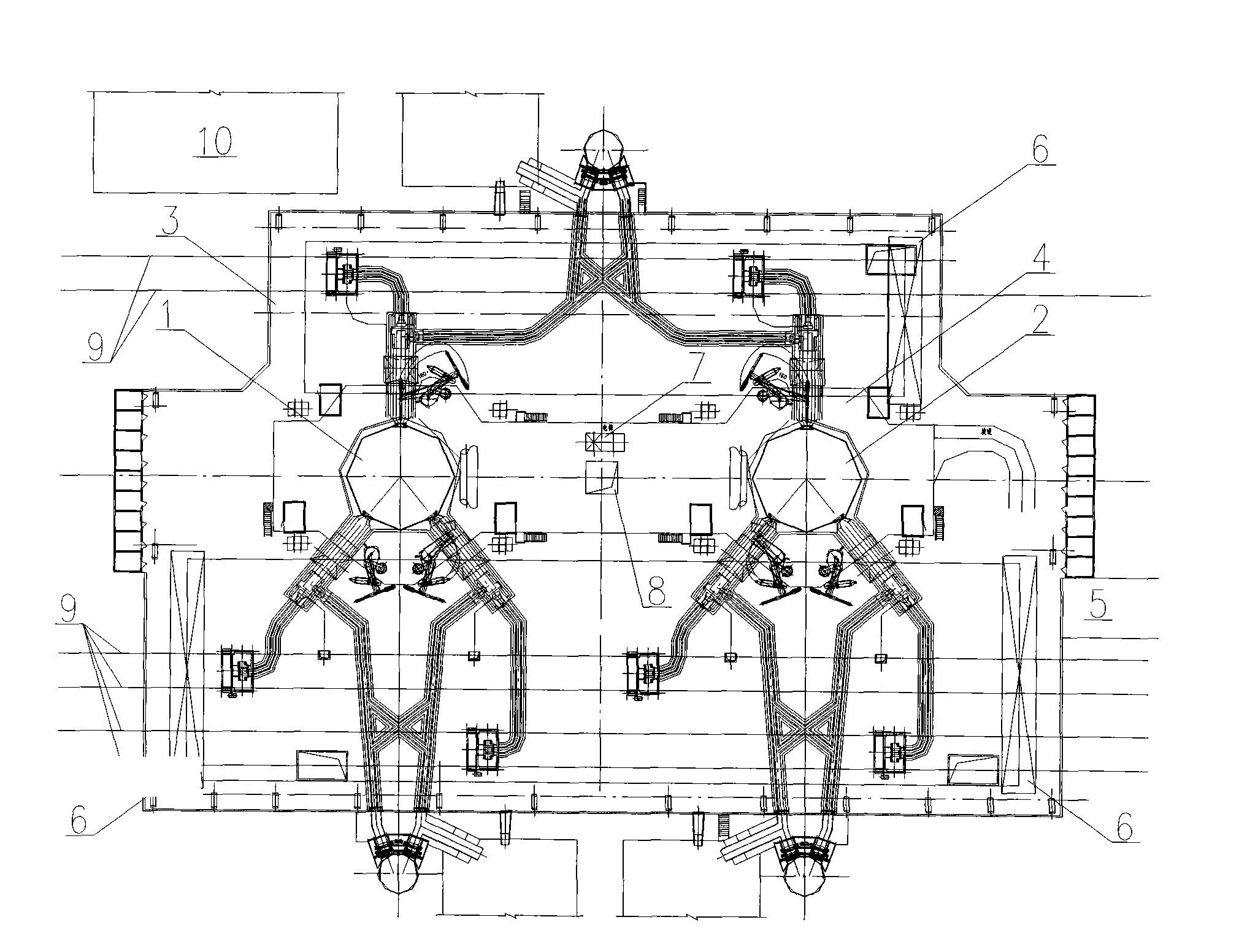

Processing arrangement of blast furnace cast house

A blast furnace tapping and tapping yard technology, which is applied to the discharge device and other directions, can solve the problems of high operation and maintenance costs, difficult layout of the general layout, long molten iron transportation lines, etc., and achieves the reduction of operation and maintenance costs, flexible layout, and investment saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] No. 1 Blast Furnace 1 and No. 2 Blast Furnace 2 are arranged in a row at a short distance, with a shared casthouse platform 3, tuyere platform 4, and a shared casthouse and casthouse factory building; cars can pass through the upper From the casthouse elevated channel 5 to the casthouse platform 3, the furnace front mobile equipment and ditch repairing machinery can also reach any position of the two blast furnaces through the casthouse, so as to realize the sharing of furnace front equipment and spare parts; The main spans of the two blast furnaces are connected, and the main span crane 6 can also be used in a backup or shared manner depending on the situation, and the hoisting dead zone of the crane is reduced, and the usable area can be increased; the furnace body elevator 7 can be arranged near the two blast furnaces The space between two blast furnaces is shared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com