Cast-in-place hollow floor with hidden protecting fume exhaust ductwork

A technology of hollow floor and smoke exhaust pipes, applied in the direction of ventilation system, vertical pipes, floor slabs, etc., can solve the problems of lower floor height space, high cost of fire-fighting smoke exhaust and ventilation system, etc., and achieve the effect of improving earthquake resistance and crack prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

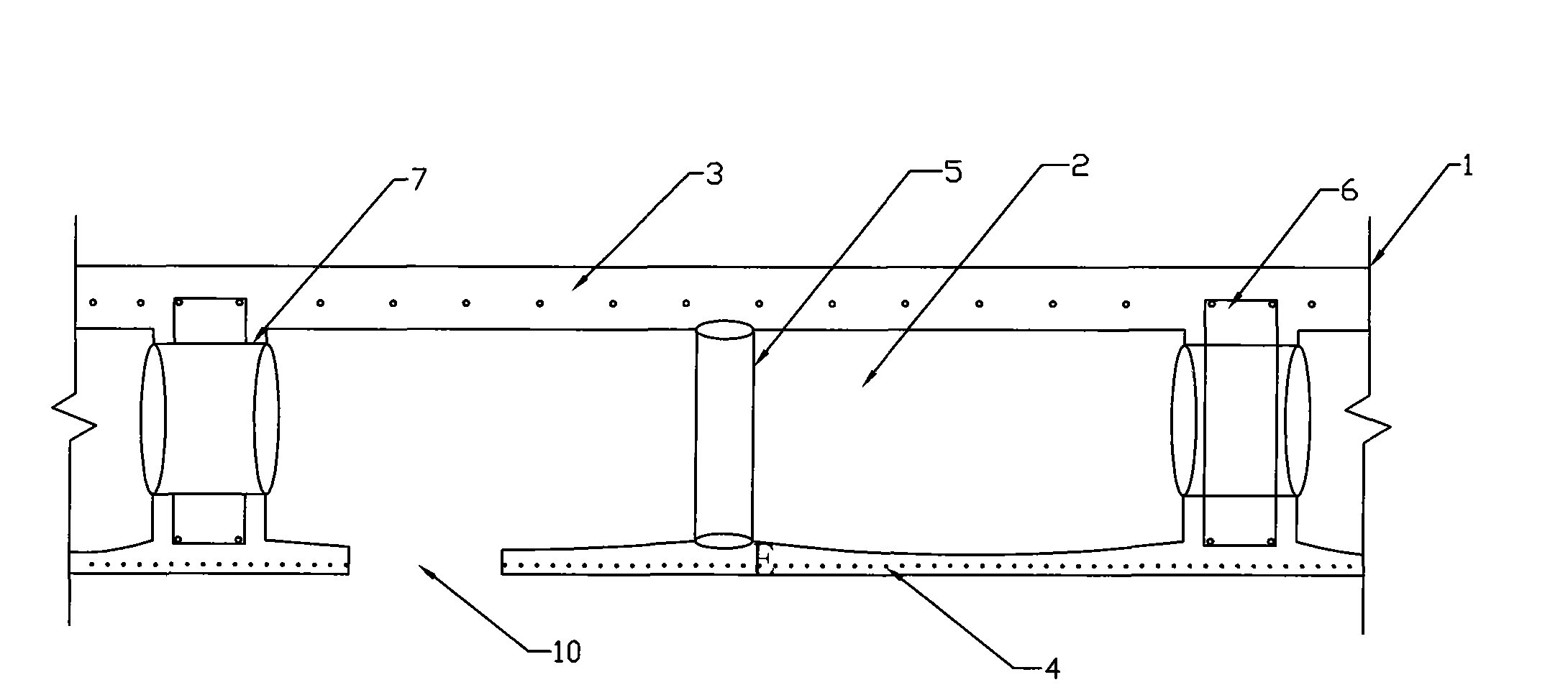

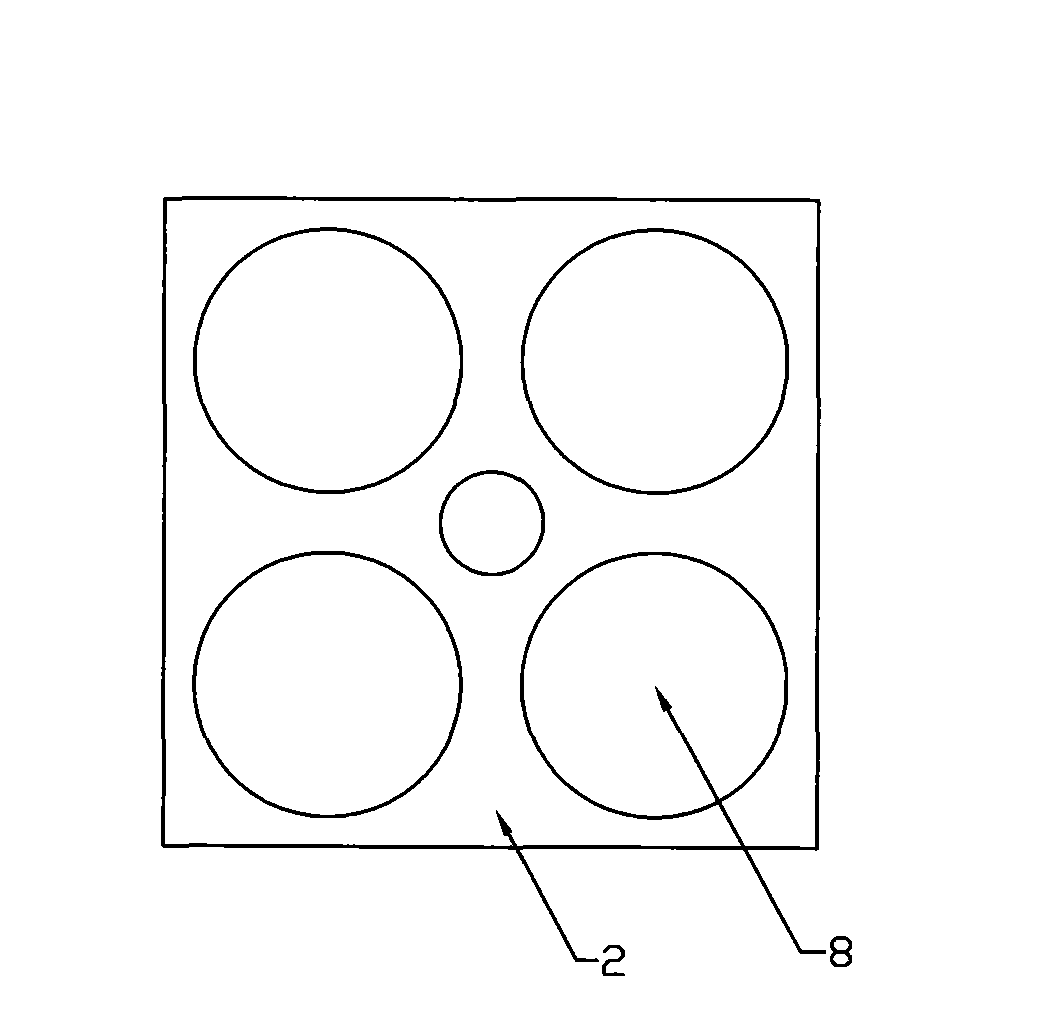

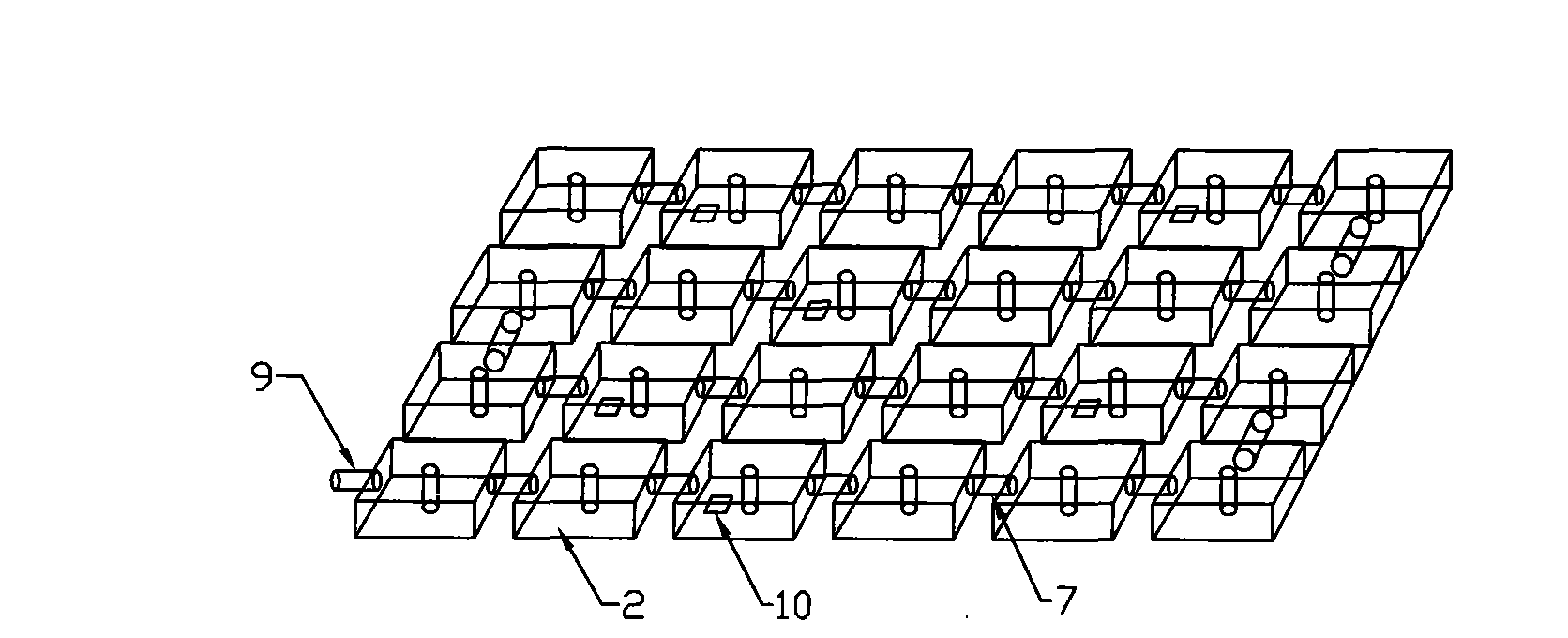

[0020] Such as figure 1 As shown, the schematic diagram of the cast-in-place hollow floor and the thin-walled box inside, the floor 1 includes the thin-walled box 2 in the middle, the upper flange plate 3, the rib beam 6, the lower flange plate 4, and the thin-walled box 2 There are multiple and cast-in-place with composite cement slurry or assembled by plates. The bottom plate of the thin-walled box body 2 has arc-shaped protrusions 8 whose height is ≤19mm, 100mm≤arc-shaped length≤300mm, and the arc-shaped protrusions on the bottom plate There are at least three arcs from 8, and the priority is to maintain balance. The bottom plate and the top cover of the thin-walled box have opposite lower holes and upper holes, and the lower holes on the bottom plate are connected to the upper holes on the top cover through closed through passages 5, 50mm≤straight diameter or side length≤180mm. The air suction port 10 of this scheme directly passes through the lower flange plate of the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com