Shape memory alloy driven retractable small actuator and control circuit thereof

A technology of memory alloy and memory alloy wire, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve the problems of large driving force and large stroke, and achieve the effect of large stroke and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

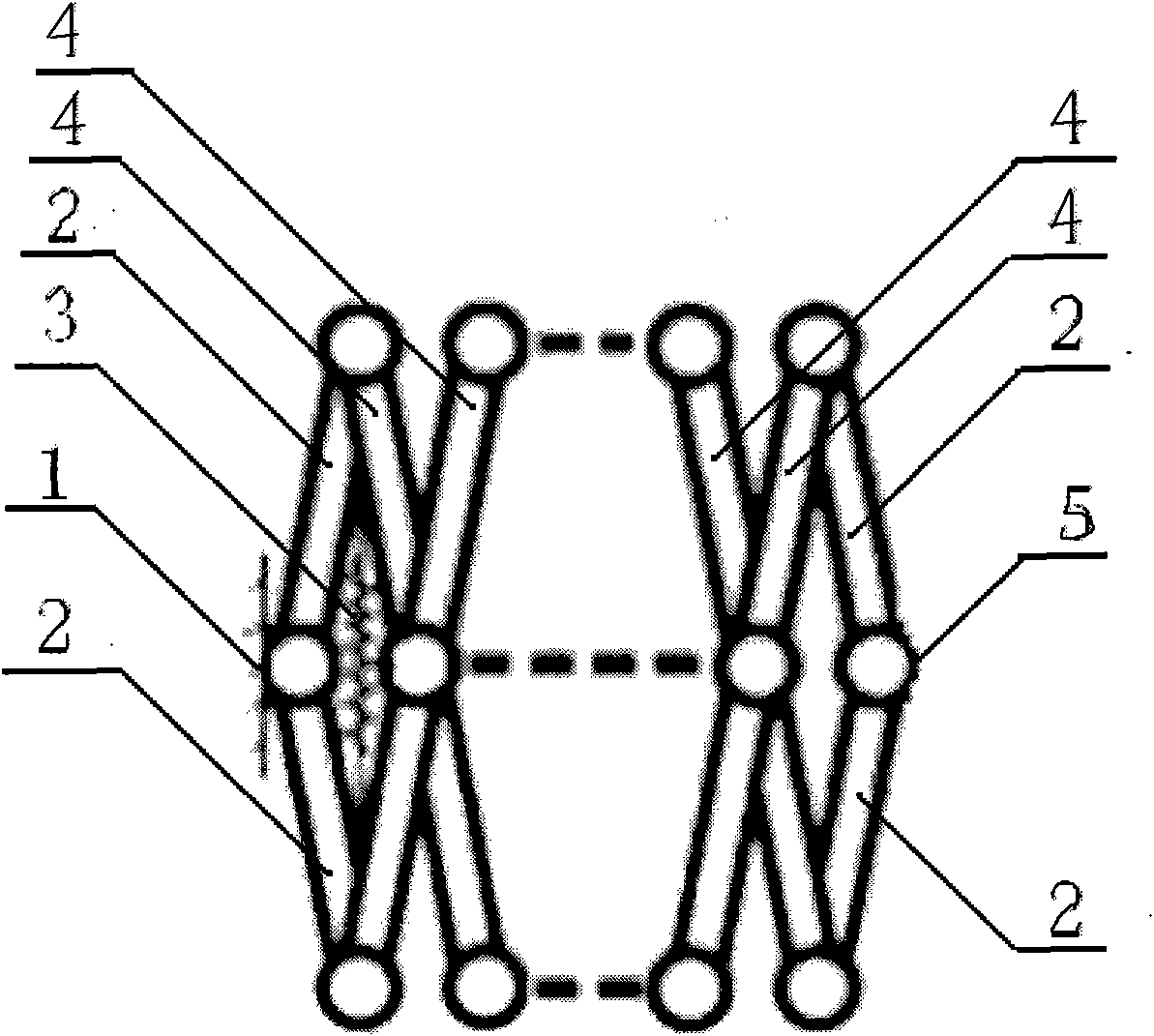

[0030] like figure 1 As shown, a shape-memory alloy-driven telescopic micro-actuator includes a fixed end 1, a return spring (not shown in the figure), a shape-memory alloy wire 3, and multiple groups connected by two long rods 4 riveted in the middle. Long rod group, four short rods 2, working end 5,

[0031] At the fixed end 1, one end of the two short rods 2 is connected by a rivet,

[0032] At the working end 5, one ends of the other two short rods 2 are connected by riveting;

[0033] Two sets of long rod groups are connected in pairs to form a long rod member, and the connection mode between two adjacent long rod groups is: one end of the two long rods 4 of one long rod group is riveted to connect with the other long rod respectively. One end of the two long rods 4 of the rod group.

[0034] The two long rods 4 of the long rod group at one end of the long rod member are respectively riveted with the other ends of the two short rods 2 of the fixed end 1 .

[0035] The...

Embodiment 2

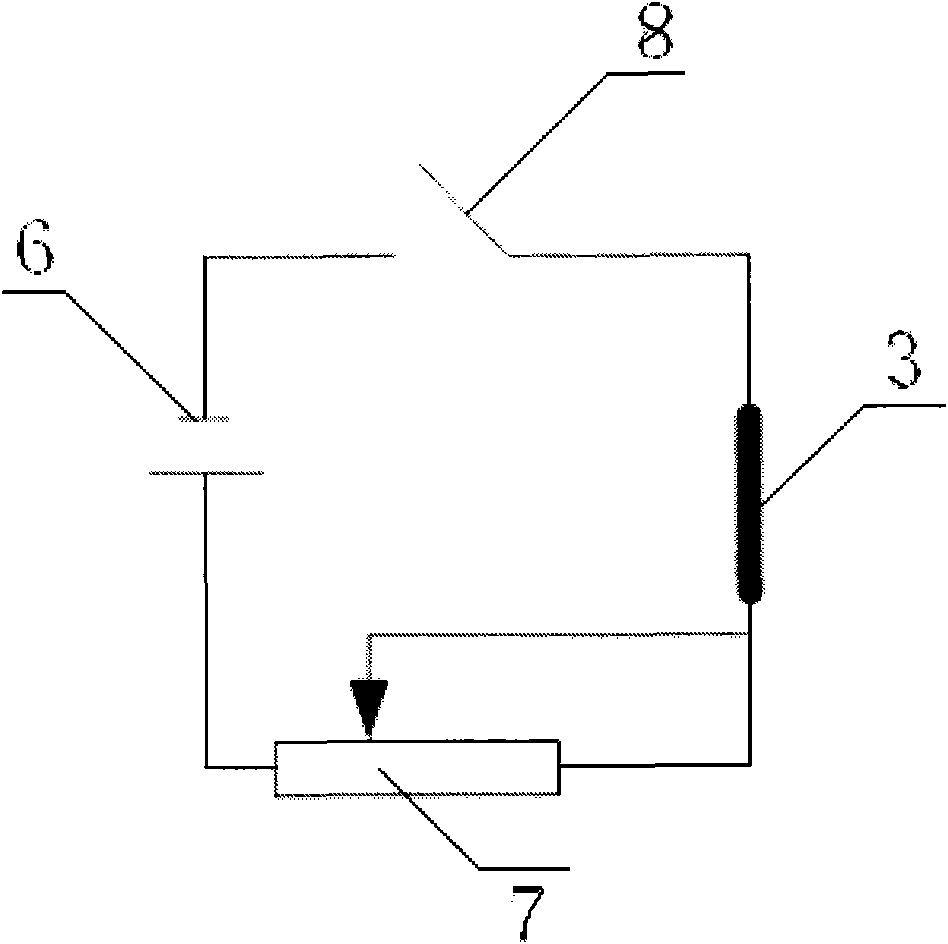

[0047] like figure 2 As shown, a control circuit for a shape memory alloy-driven retractable micro-actuator adopts the shape-memory alloy-driven retractable micro-actuator described in Embodiment 1, including a DC power supply 6 , a sliding resistor 7 , and a switch 8 . The DC power supply 6, the sliding resistor 7, the shape memory alloy wire 3 for driving the retractable micro-actuator and the switch 8 are connected in series in sequence.

[0048] Its control principle is as follows:

[0049] The closing and opening of the switch 8 controls the energization and de-energization of the shape memory wire 3, thereby controlling the action of the shape memory alloy to drive the telescopic micro actuator, that is, the telescopic micro actuator is stretched when the switch is closed, and the telescopic micro actuator is stretched when the switch is opened. The retractable micro-actuator shrinks, and when the sliding rheostat 7 slides, the resistance of the circuit is changed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com