Anti-torsion energy dissipater with internal collision-friction-deformation three-stage energy dissipation

An energy dissipator and anti-torsion technology, which is applied in the direction of friction shock absorbers, building components, and anti-shock, can solve the problems of passive dampers with residual deformation, only axial vibration reduction ability, and limited energy dissipation capacity, etc., and achieve recovery Large deformation, convenient torsion design, and improved energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation steps of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0017] Step 1. Analyze the engineering structure, calculate the torsional force to be controlled, and determine the size and parameters of the energy dissipator according to the performance requirements to be achieved.

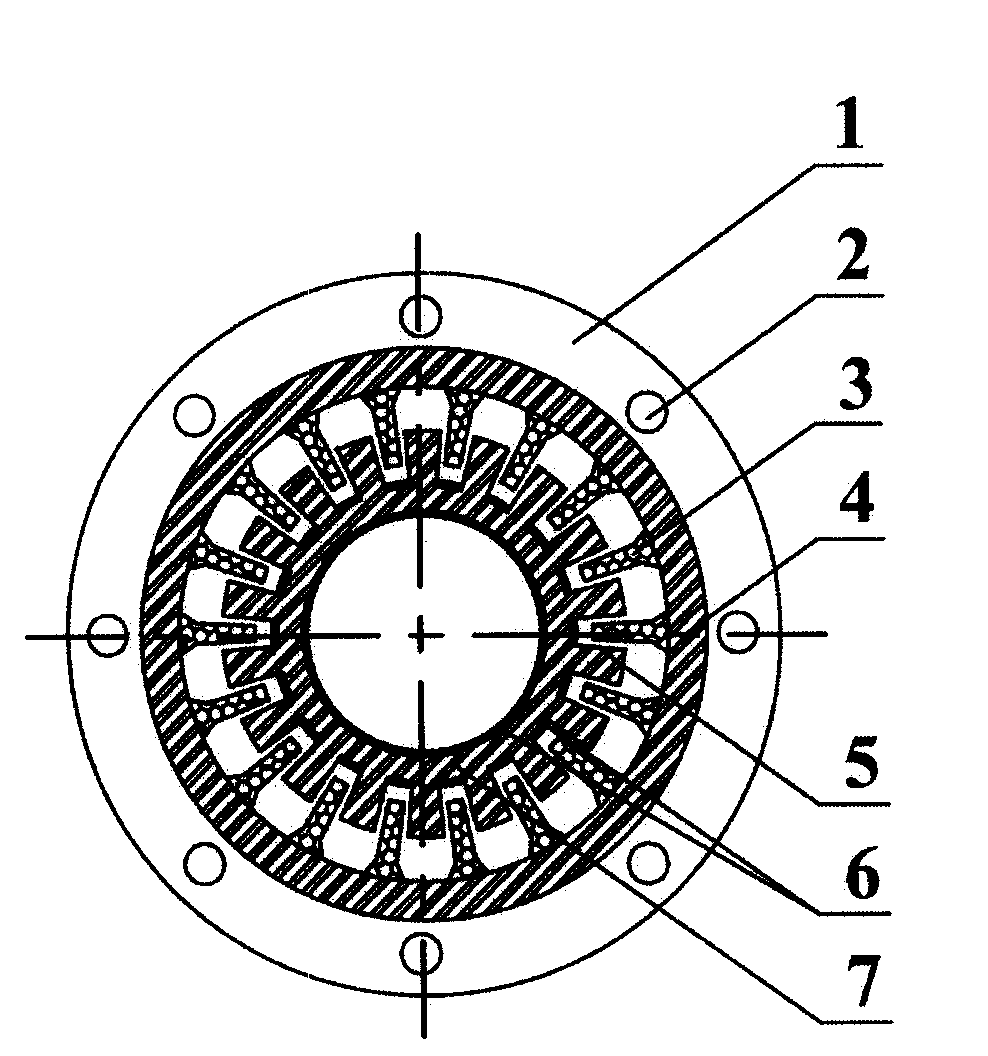

[0018] Step 2. Arrange 18 sets of spacer steel plates 5 evenly and symmetrically in the radial direction on the outer circumference of the inner steel cylinder 7 , and arrange 18 sets of shape memory alloy spacer plates 3 evenly and symmetrically in the radial direction on the inner circumference of the outer steel cylinder 4 .

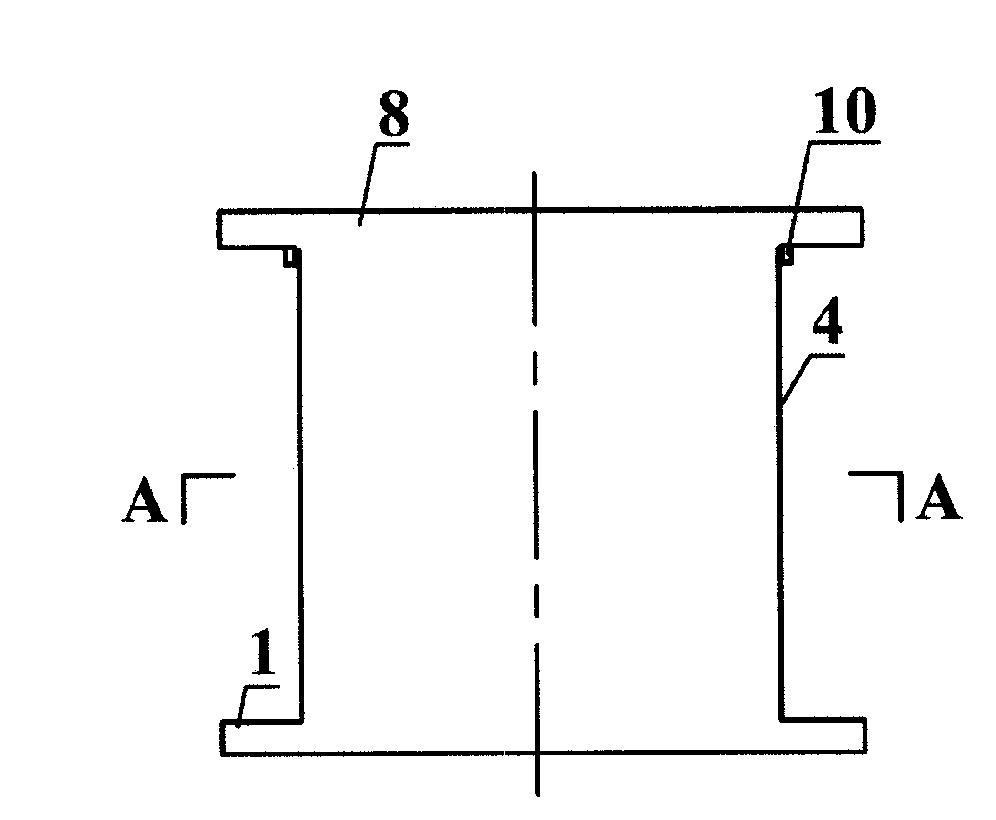

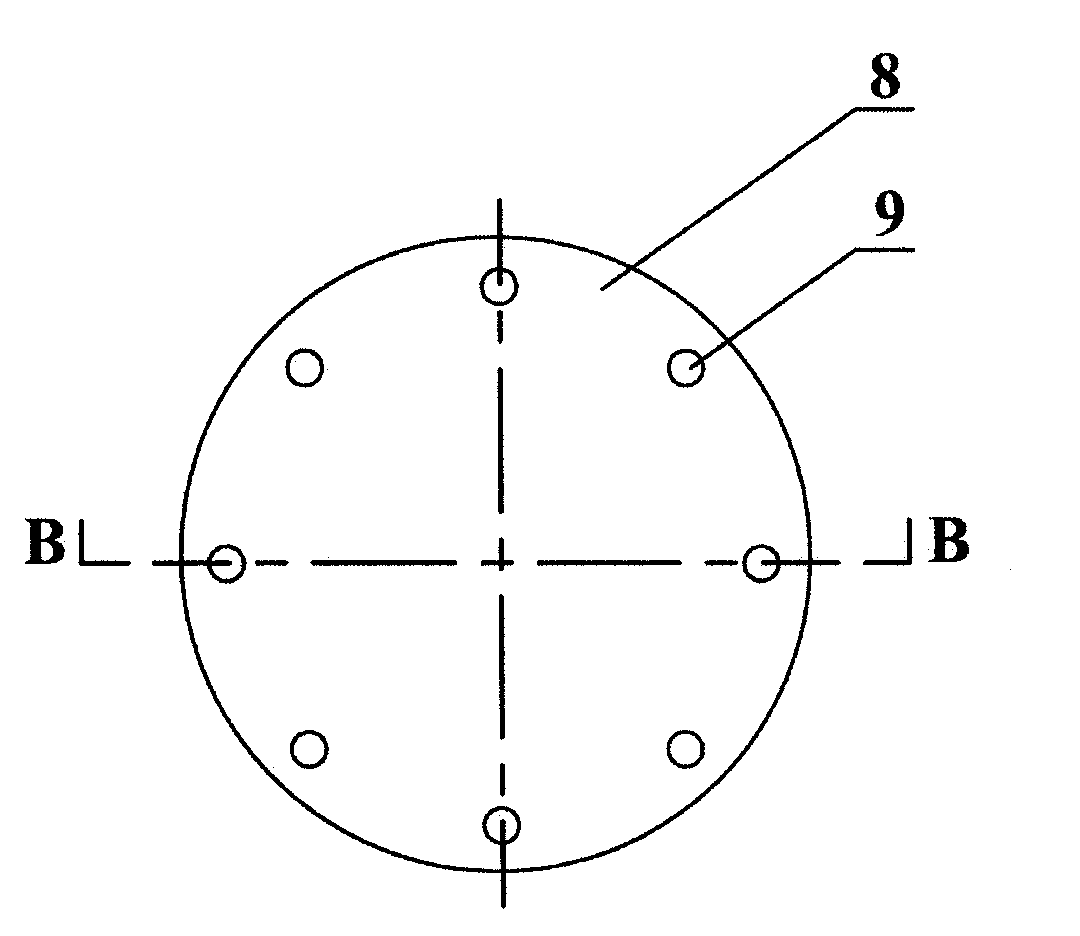

[0019] Step 3. Make a steel chute 10 on the upper flange 8 with the same radius as the outer steel cylinder 4; make a steel chute 6 on the lower flange 1 with the same radius as the inner steel cylinder 7 same.

[0020] Step 4. Weld the outer steel cylinder 4 to the lower fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com