Automatic-lifting type insulating platform used for hot-line work

A live working, automatic lifting technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of unable to use concrete poles to automatically lift, unable to provide an insulating platform for live working, etc., to make up for limitations, make up for road restrictions, and reduce safety. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

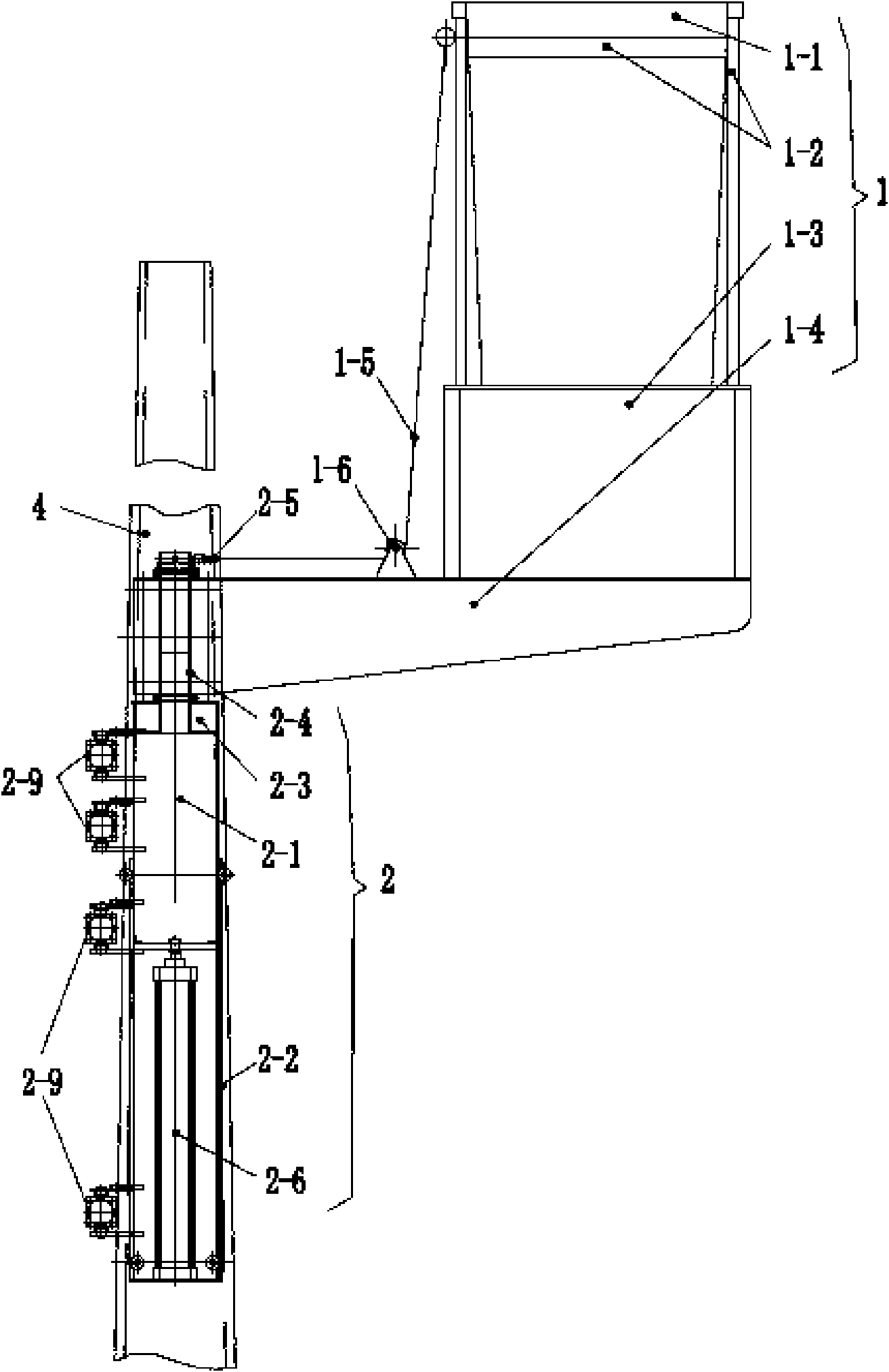

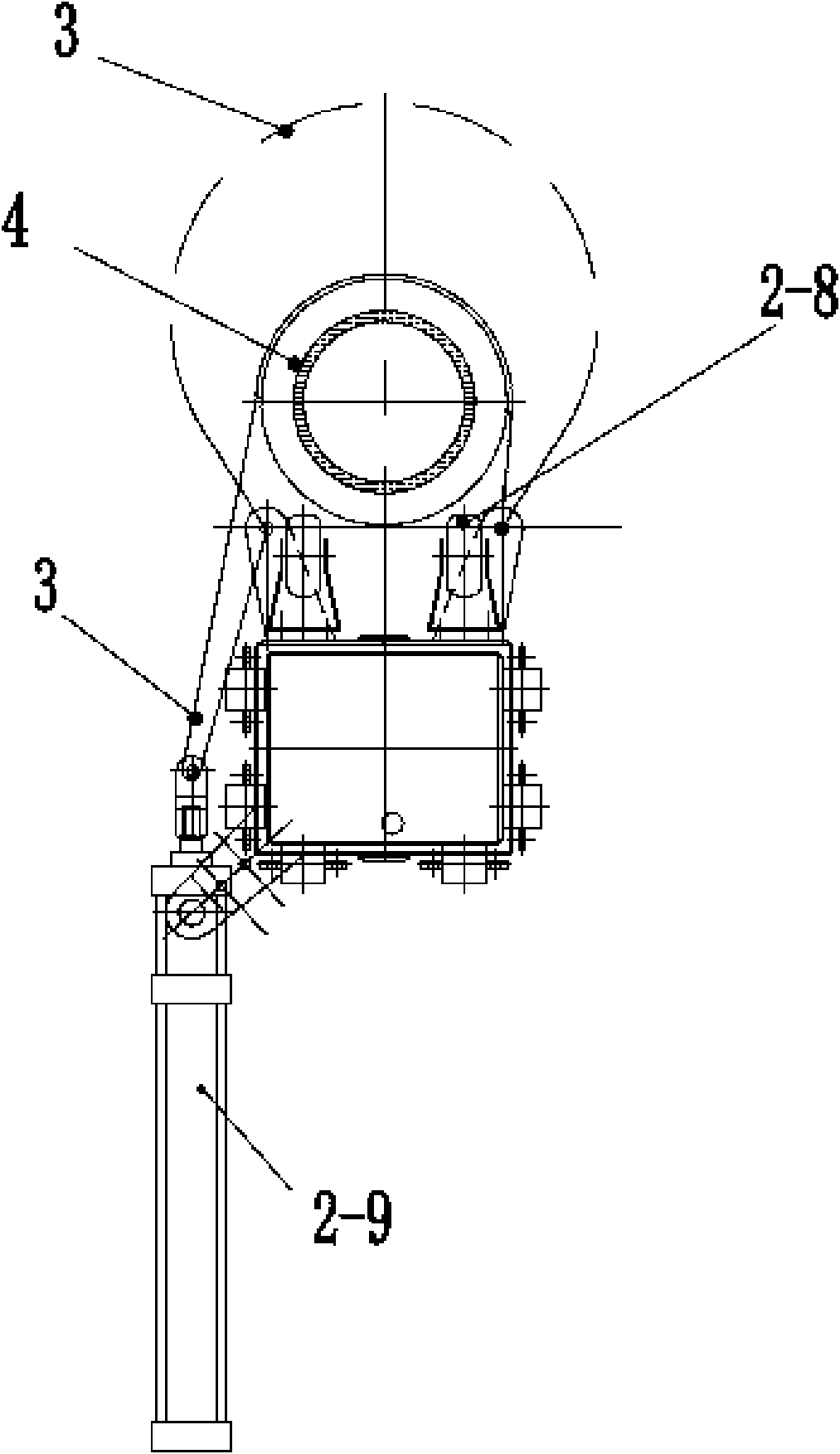

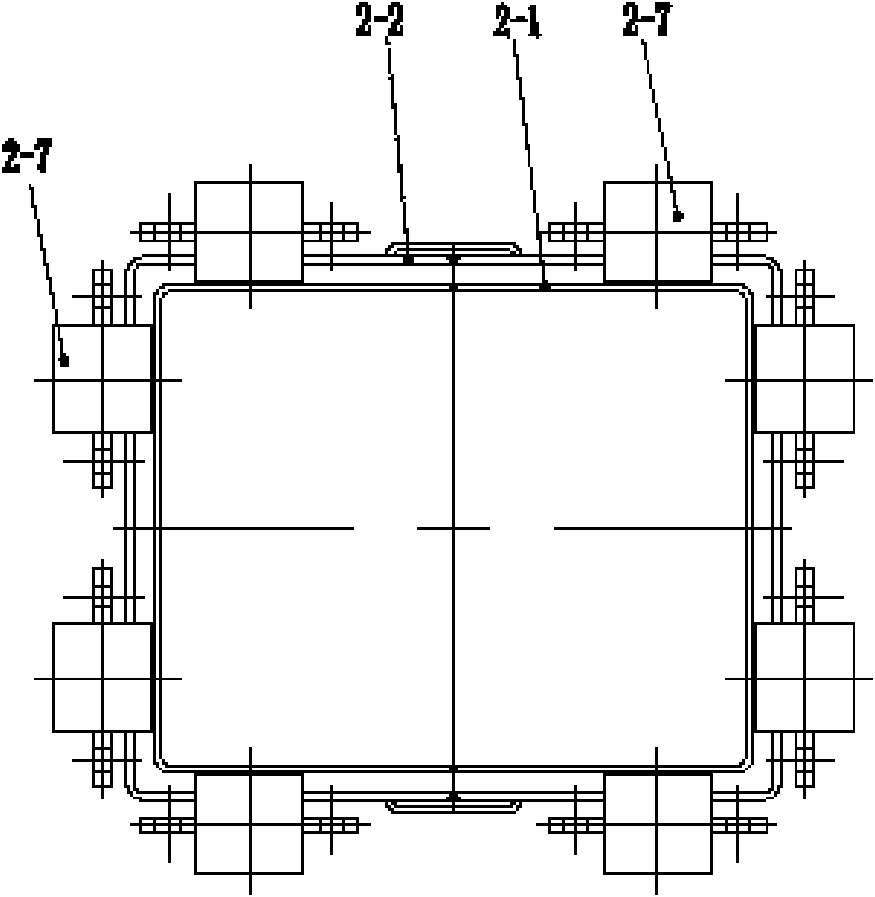

[0020] See Figure 1-6 , the self-lifting insulating platform for live work of this implementation includes: an automatic climbing device 2 and an insulating rotating platform 1 located on the automatic climbing device 2; the automatic climbing device 2 includes: an inner cylinder 2-1 and an outer cylinder connected up and down 2-2, and the climbing cylinder 2-6 used to control the relative displacement of the inner cylinder 2-1 and the outer cylinder 2-2; the inner cylinder 2-1 and the outer cylinder 2-2 are opposite to the concrete rod 4 when in use At least one pair of guide wheels 2-8 arranged in parallel and equal height, and a pair of climbing flat belts 3 for being sleeved on the concrete pole 4 are respectively provided on the rear side of the inner cylinder 2-1 and the outer cylinder 2-2. At least one pair of locking cylinders 2-9 for tightening the climbing flat belt 3 are respectively provided on the left side. The head of the movable shaft of the locking cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com