Pneumatic tire

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, special tires, tire parts, etc. It can solve the problems of poor adhesion, difficulty in suppressing air leakage, and failure to solve the adhesion between the air-proof layer and the surrounding rubber layer. Excellent adhesion without deteriorating durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

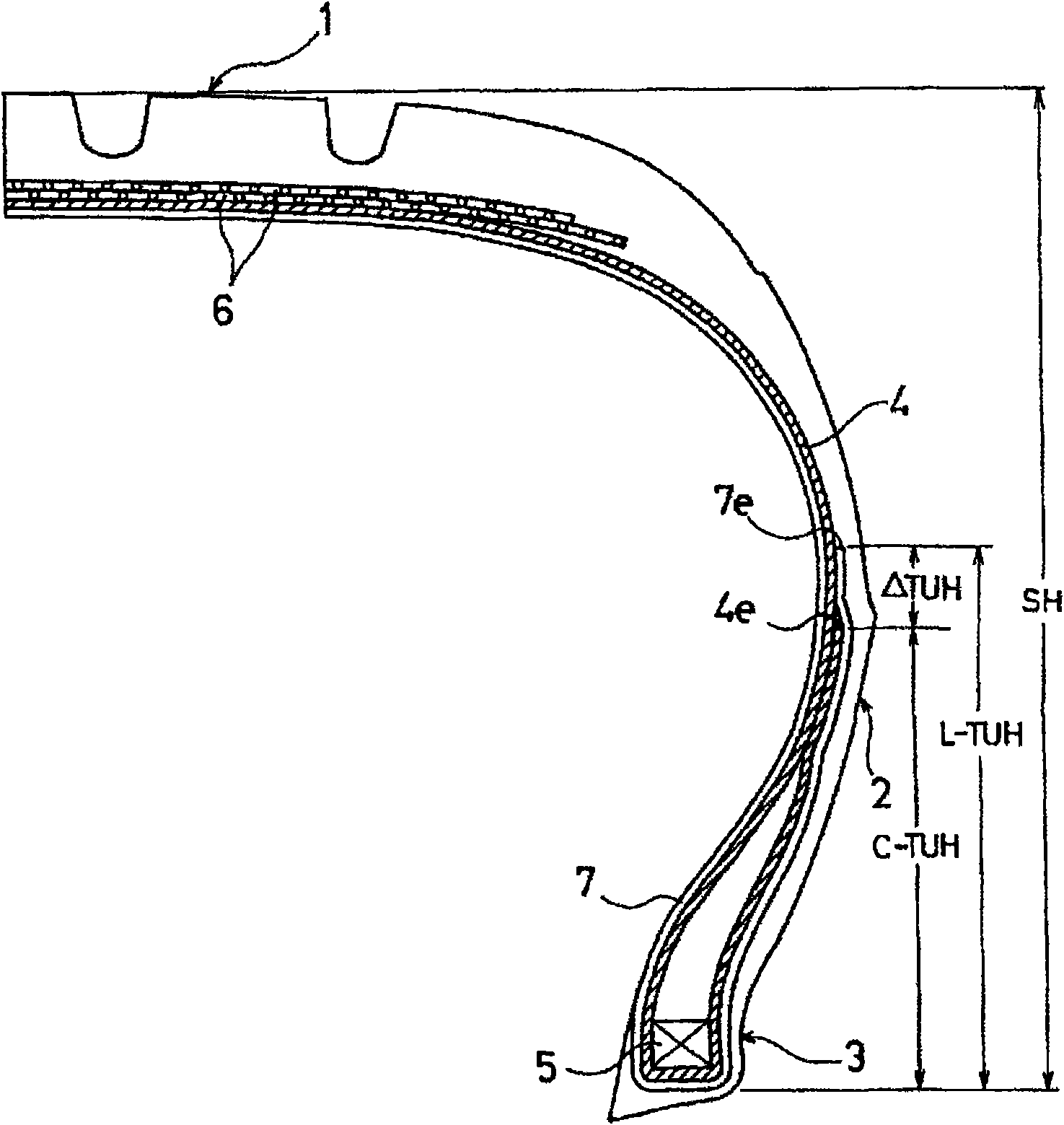

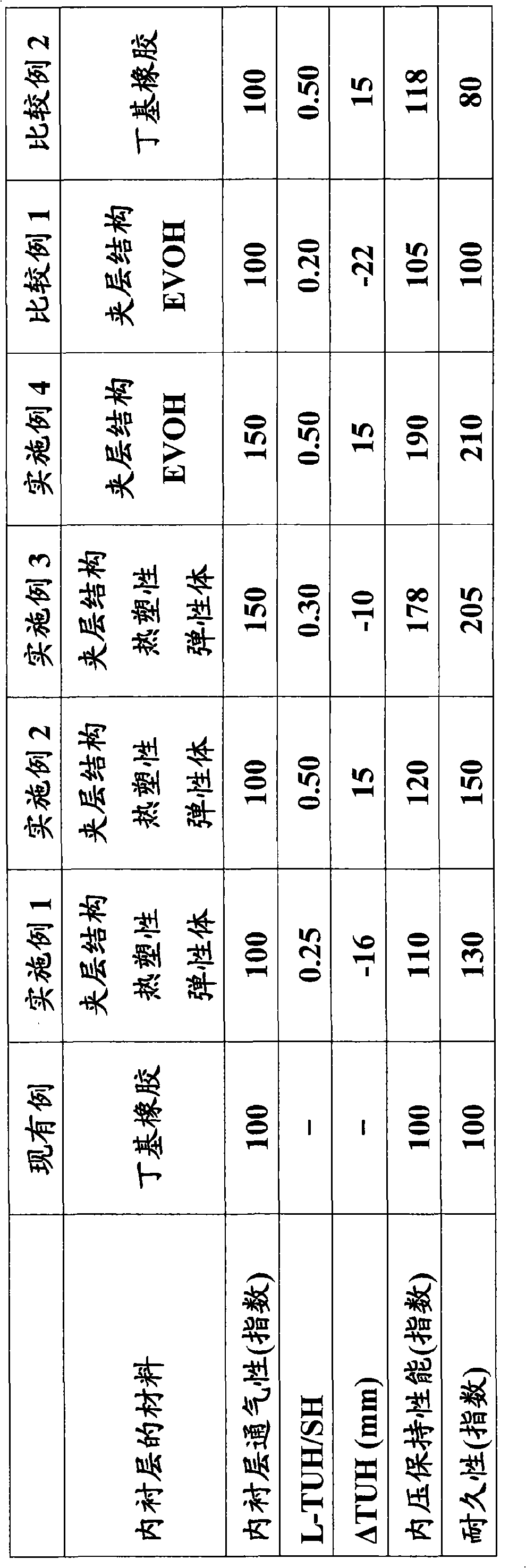

[0045] Tires of Conventional Example, Examples 1-4, and Comparative Examples 1-2 were produced. The tire size is 195 / 60R15. In these tires, a carcass layer containing a plurality of reinforcing cords is spanned between a pair of bead portions, and the carcass layer is wound around the bead core from the inner side to the outer side of the tire. The constituent material of the inner liner on the inner cavity side, the ratio of the turn-up height (L-TUH) of the inner liner to the tire section height (SH) (L-TUH / SH), and the turn-up height of the carcass layer ( The difference (ΔTUH) between C-TUH) and the rolled-up height (L-TUH) of the inner liner is different.

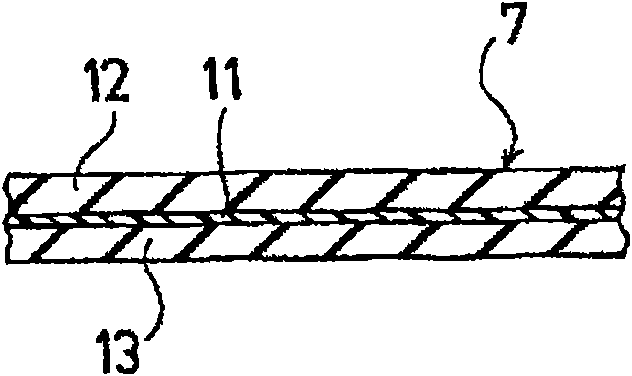

[0046] The tire of the conventional example employs an inner liner layer having a thickness of 0.5 mm formed of a rubber composition mainly composed of butyl rubber, and the inner liner layer is terminated on the inner surface of the tire. The tires of Examples 1 to 3 employ an inner liner with a thickness of 0.5 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com