Fireproof coated board

A technology of fire-resistant coating and fire-resistant coating layer, which is applied in the direction of layered products, natural mineral layered products, chemical instruments and methods, etc., can solve the problems of inconvenient construction, high cost, hard texture, etc., and achieve fire-proof and flame-retardant effects Good, easy to transport and construct, easy to cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

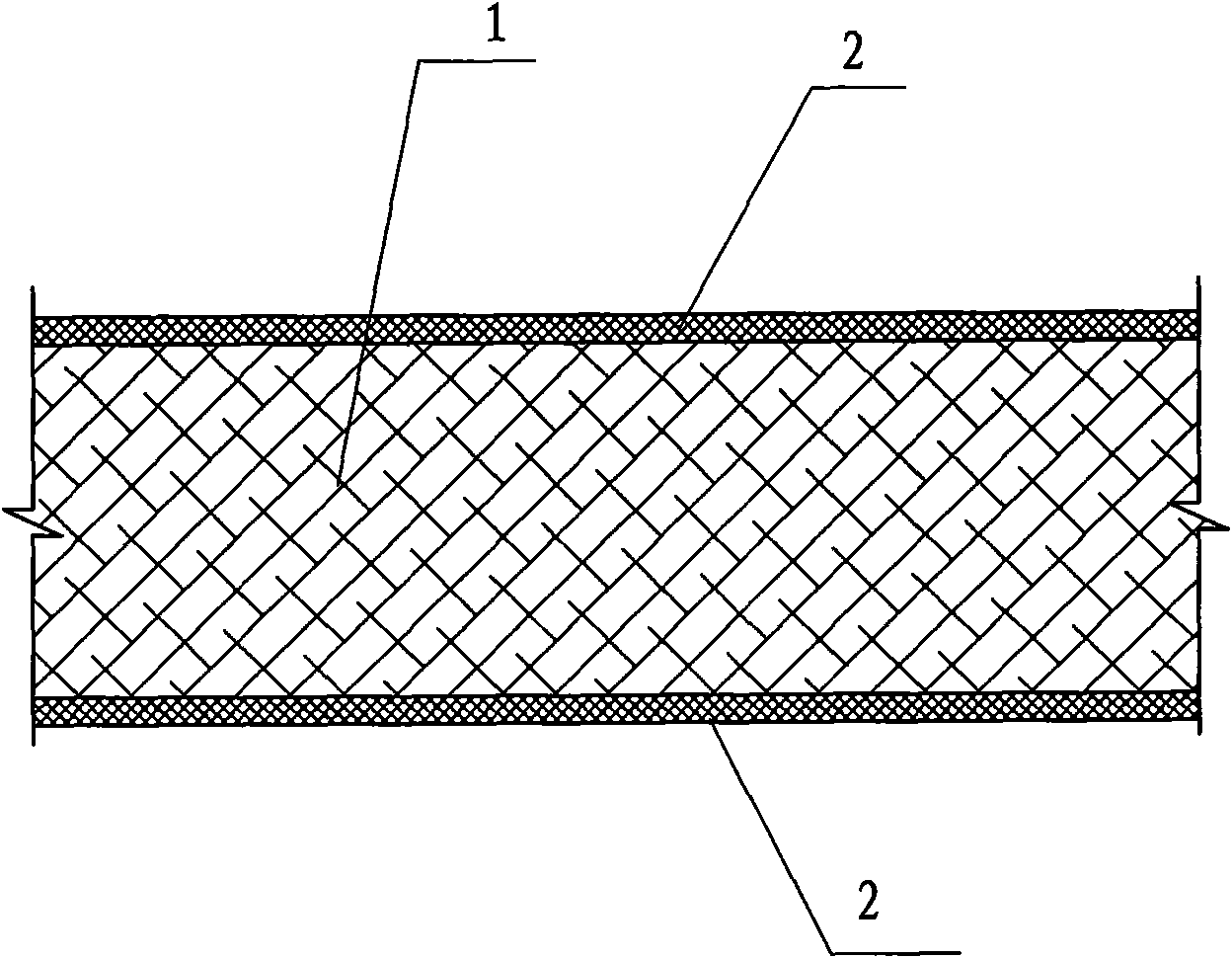

[0007] As shown in the figure, the fireproof coating board consists of a rock wool board base layer 1 and a fireproof coating layer 2 coated on both sides of the rock wool board base layer. Its fireproof coating layer can directly use conventional various types of cable fireproof coatings.

[0008] Scope of application of the present invention:

[0009] 1. Applicable to electric power, metallurgy, petrochemical, post and telecommunications industries, fire protection and fire-resistant separation of cables with various voltage levels;

[0010] 2. Suitable for large openings; single or multiple pipelines; fire separation of cables, cable bundles and cable trays, flammable pipes, metal pipes, and HVAC air ducts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap