High-radiating light-emitting diode module and light-emitting diode lamps

A technology of light-emitting diodes and high heat dissipation, which is applied to semiconductor devices of light-emitting elements, light sources, point light sources, etc., and can solve the problems of reduced lighting brightness, large volume, and difficulty in increasing the number of radiators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

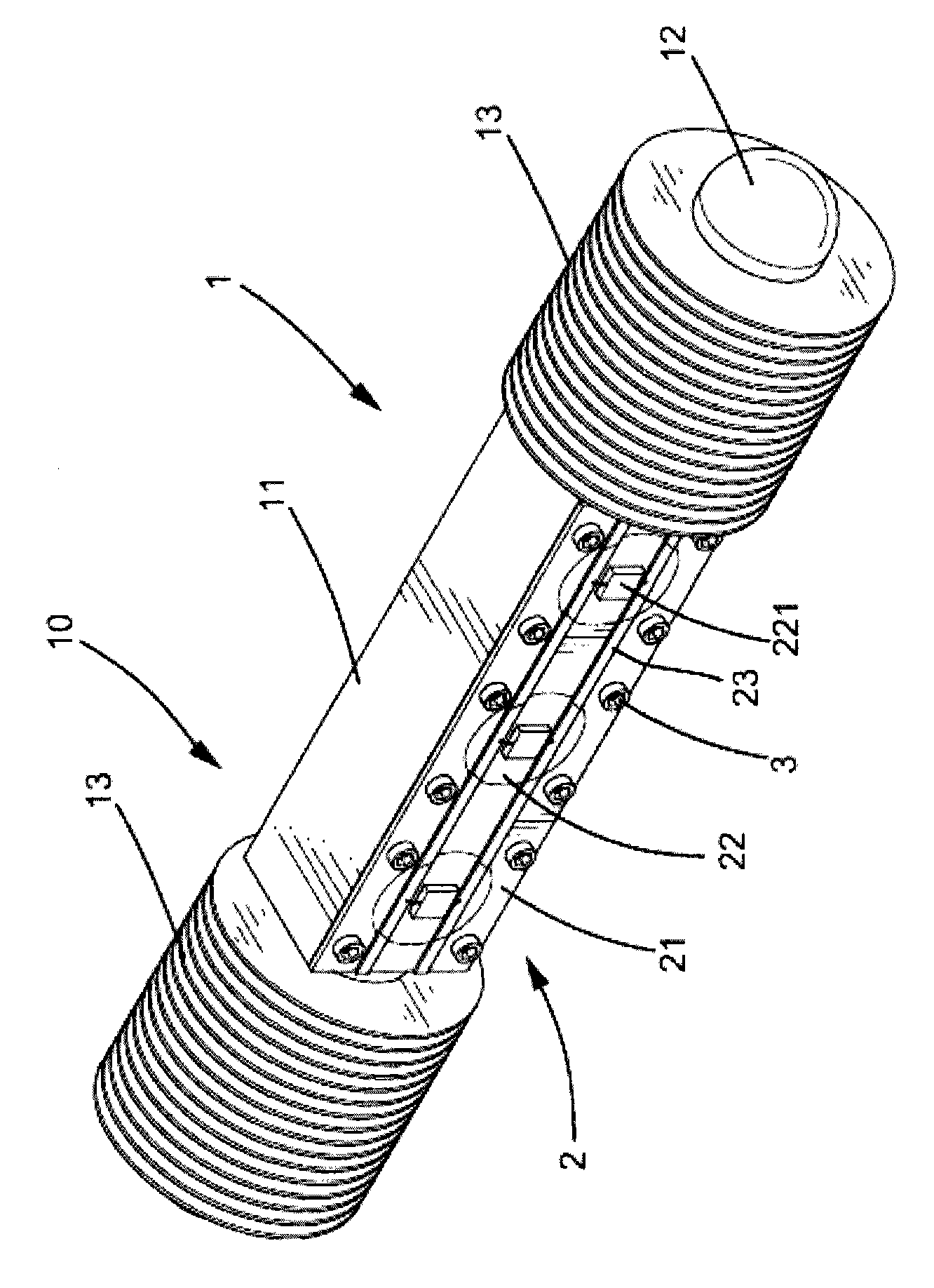

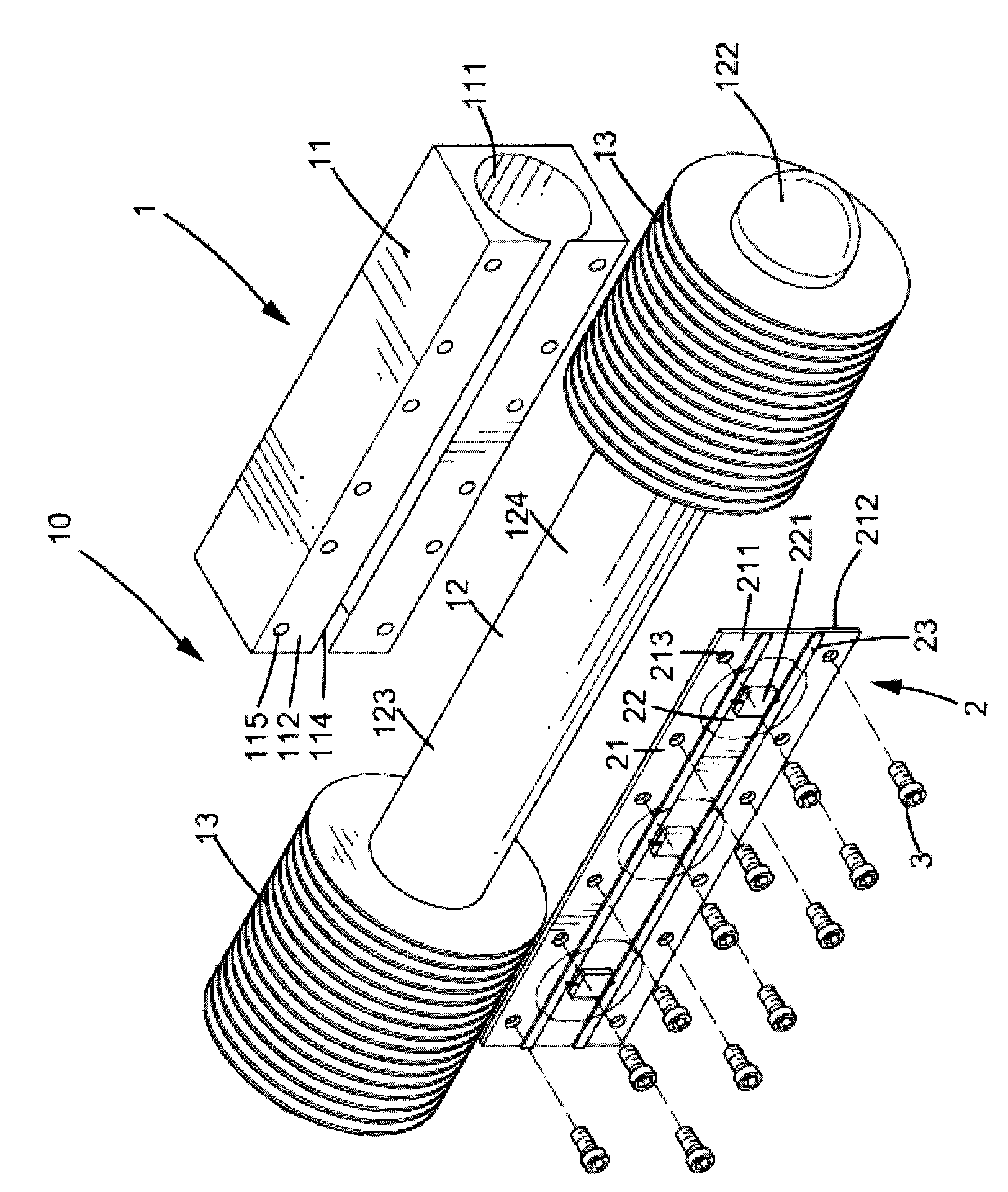

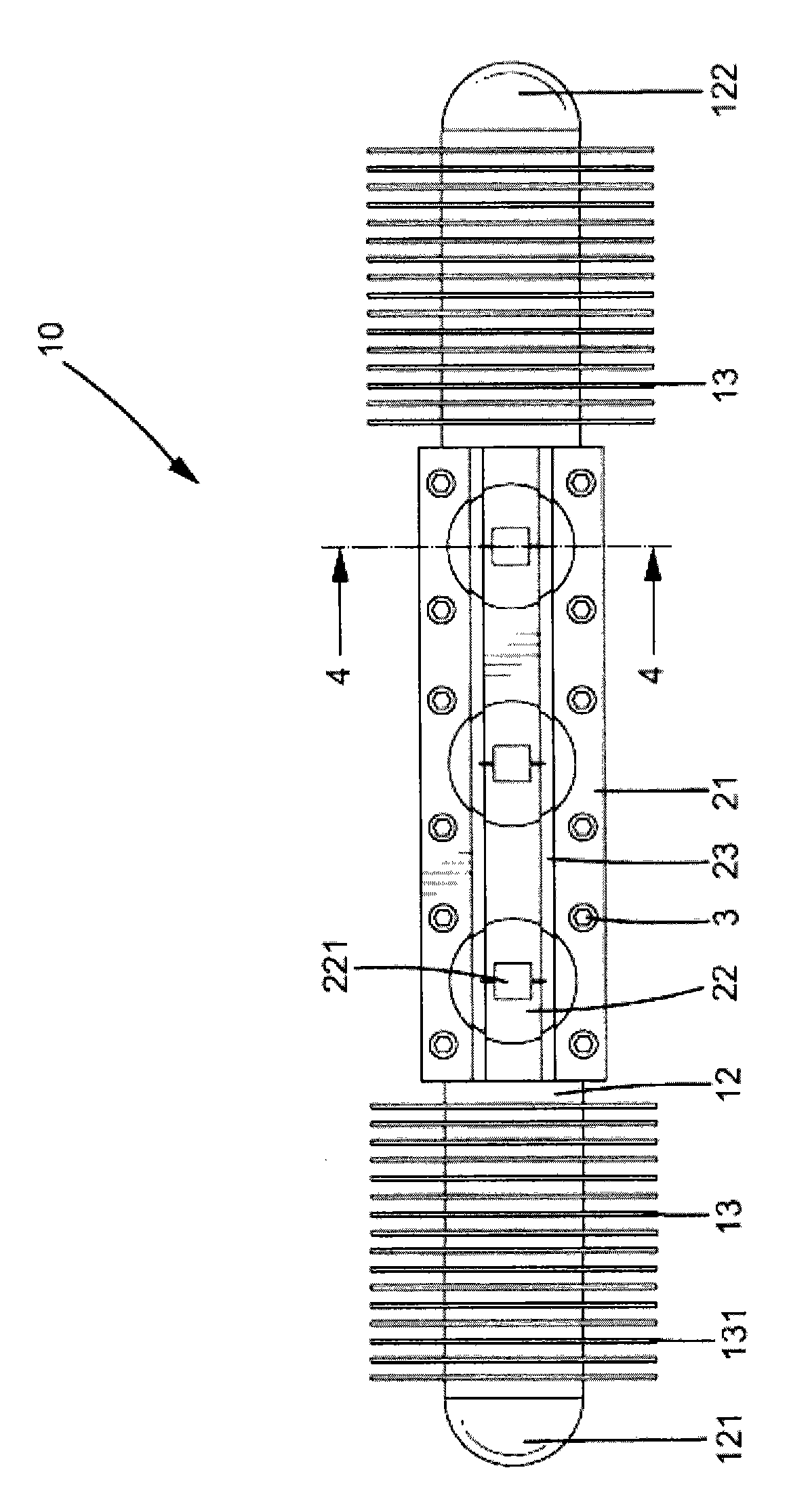

[0065] see Figure 1 to Figure 4 , shows the LED module 10 according to the first embodiment of the present invention; the LED module 10 includes an LED light source assembly 2 and a heat dissipation module 1 .

[0066] The light emitting diode light source assembly 2 includes a substrate 21 made of metal material and a plurality of light emitting diodes 22; the metal substrate has a first surface 211 and a second surface 212 opposite to each other, and a circuit board 23 is combined on the first surface 211 Each light emitting diode 22 is combined on the first surface 211 of the substrate and includes at least one light emitting diode chip 221 electrically connected to the circuit board 23 . In this embodiment, the substrate 21 is provided with a plurality of through holes 213, and the thickness of the substrate 21 is 0.5-1 mm.

[0067] The heat dissipation module 1 includes a heat dissipation body 11, a heat pipe 12 and two fin radiators 13; the interior of the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com