Multi-variant spherical travelling-wave ultrasonic motor moment measuring device

An ultrasonic motor and torque measurement technology, applied in the direction of measurement device, torque measurement, generator/motor, etc., can solve the problems of dynamometer measurement, high torque density of multi-degree-of-freedom ultrasonic motor, difficult measurement, etc., and achieve a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, and the object and effect of the present invention will become more apparent.

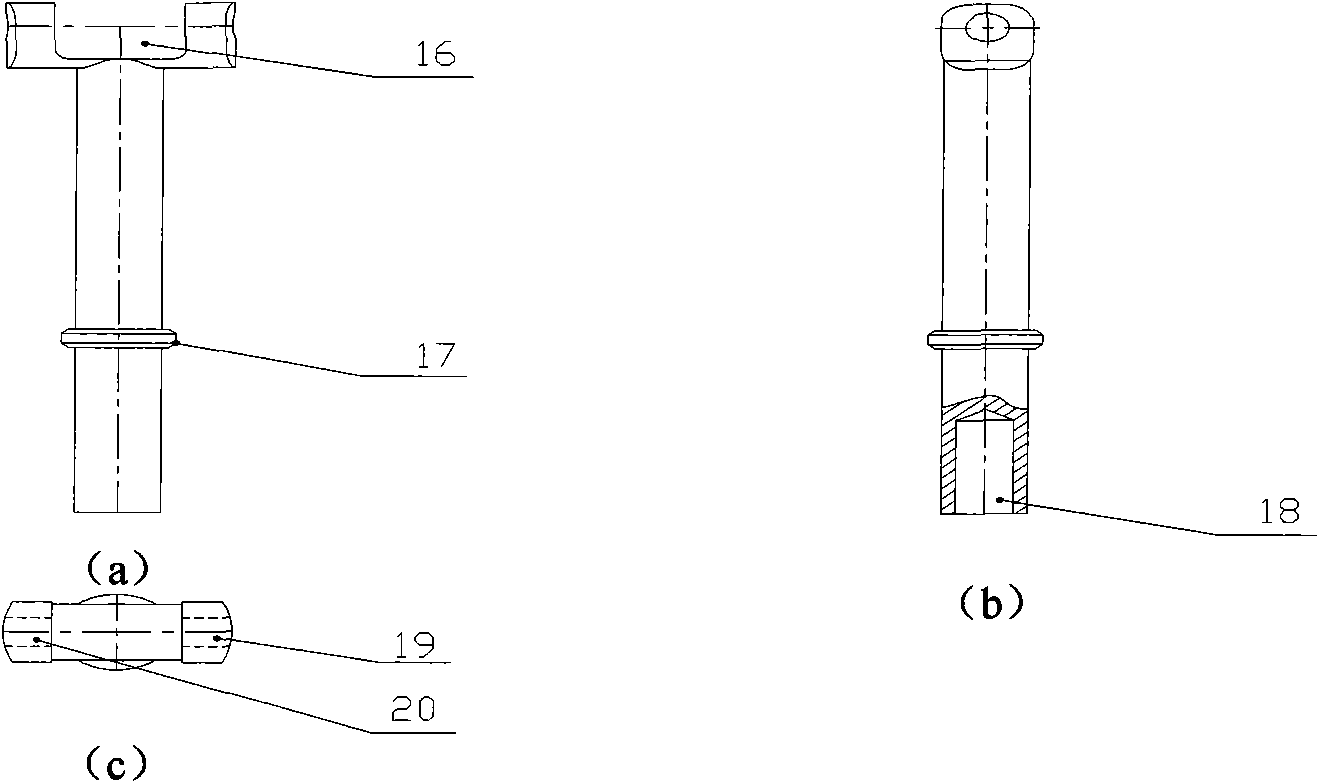

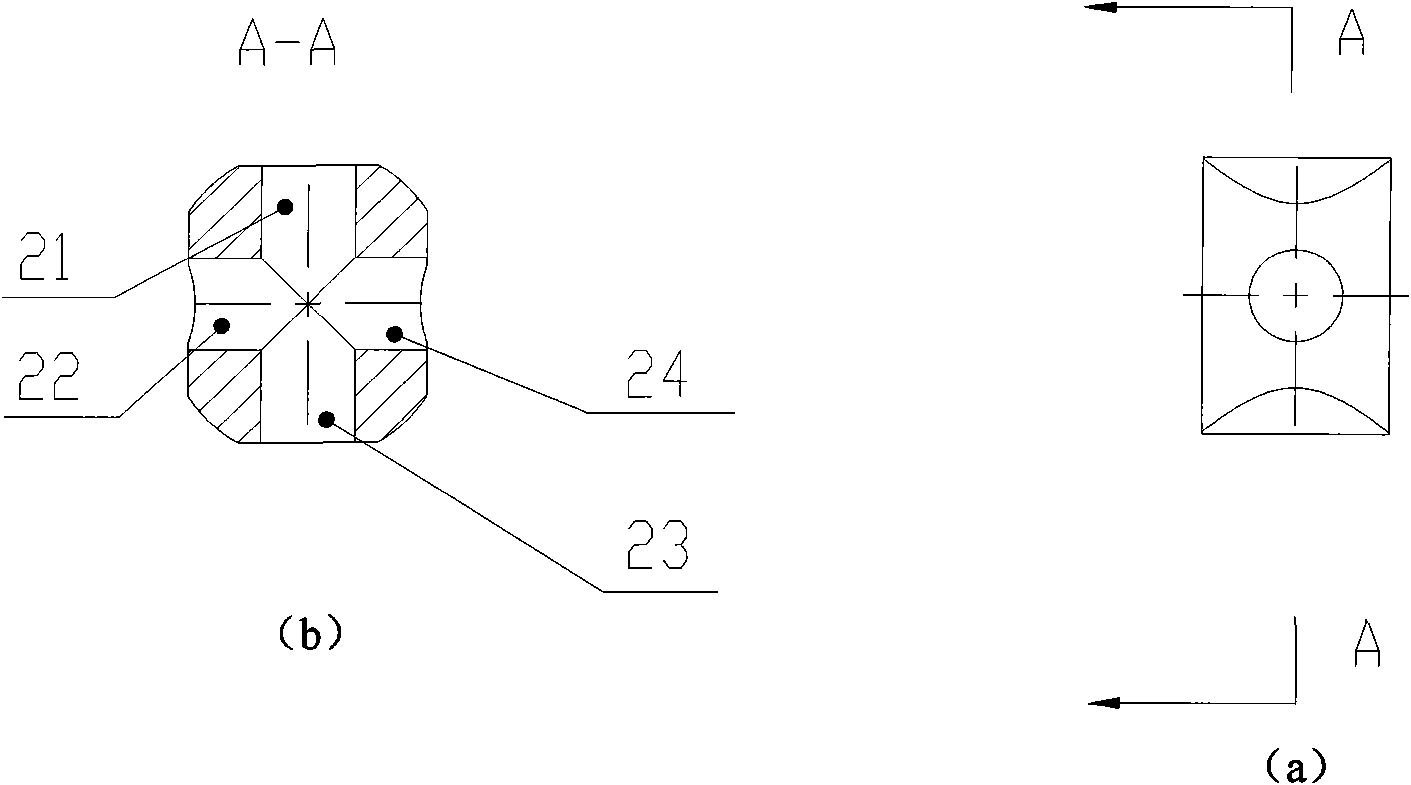

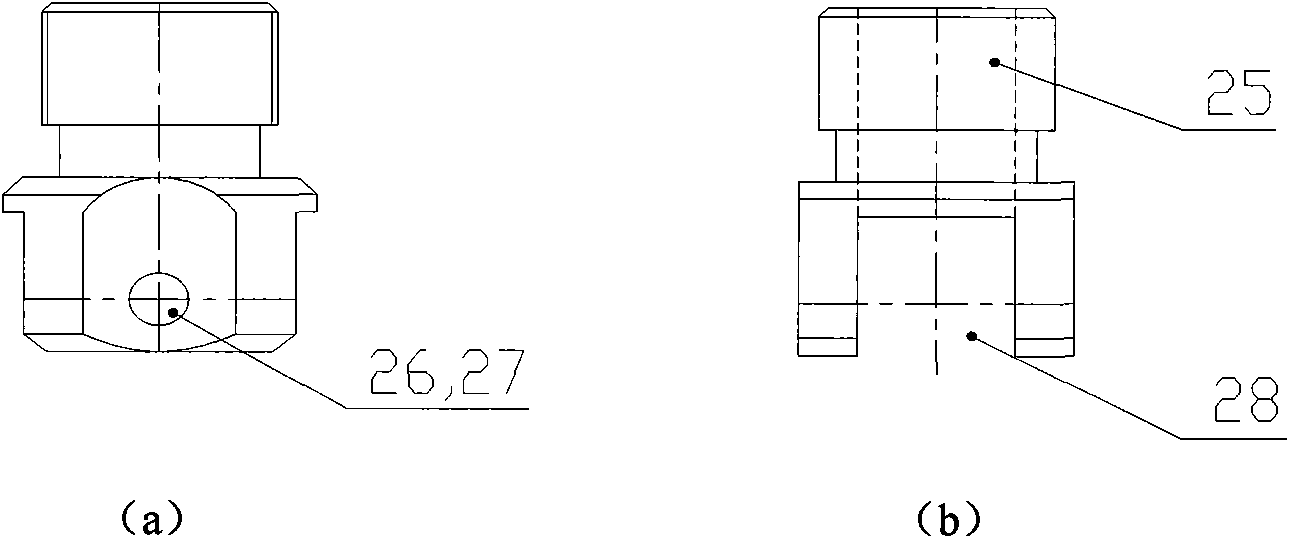

[0023] like Figure 7 As shown, the multi-degree-of-freedom spherical traveling wave ultrasonic motor torque measuring device of the present invention comprises: a mandrel 1, a universal joint 2, an upper cover 3, a lower cover 4, a first hardwood concave indenter 5, a base 6, Cross head 7 , short mandrel 8 , force measuring rod 9 , bent plate 10 , bracket 11 , pressure sensor 12 and second hardwood concave indenter 34 . Among them, the upper end of the force measuring rod 9 is connected with the cross head 7 through the short mandrel 8, and is connected with the universal joint 2 through the mandrel 1, and the connection between the force measuring rod 9 and the cross head 7 and the universal joint 2 is The clearance fit allows the force measuring rod 9 to have a small range of motion in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com