Cable coil quality detection apparatus

A technology of detection device and cable reel, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. It can solve difficult tension control, affect the progress of product testing, and unwinding process does not conform to actual use conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

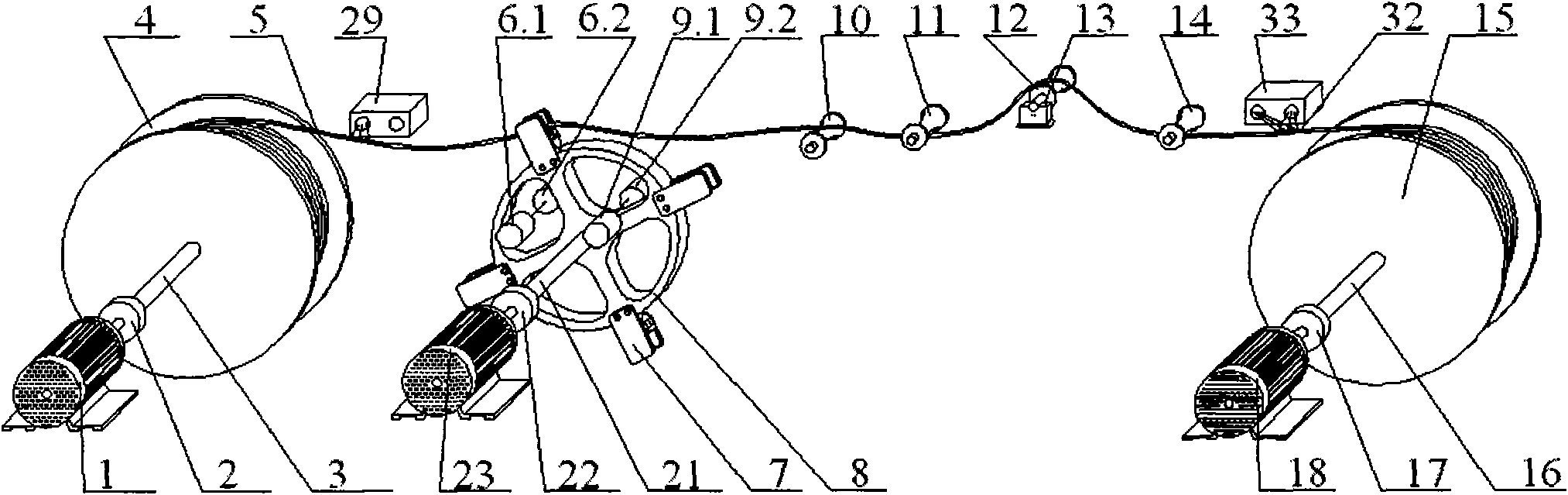

[0029] Such as figure 1 As shown, the present invention includes a cable reel portion, an auxiliary reel portion and a grip wheel portion; wherein:

[0030] Cable reel part: the cable reel 4 is installed on the first shaft 3, and the first shaft 3 is connected to the first motor 1 through the first electromagnetic clutch 2;

[0031] Auxiliary reel part: the auxiliary reel 15 is installed on the second shaft 16, and the second shaft 16 is connected with the second motor 18 through the magnetic powder clutch 17;

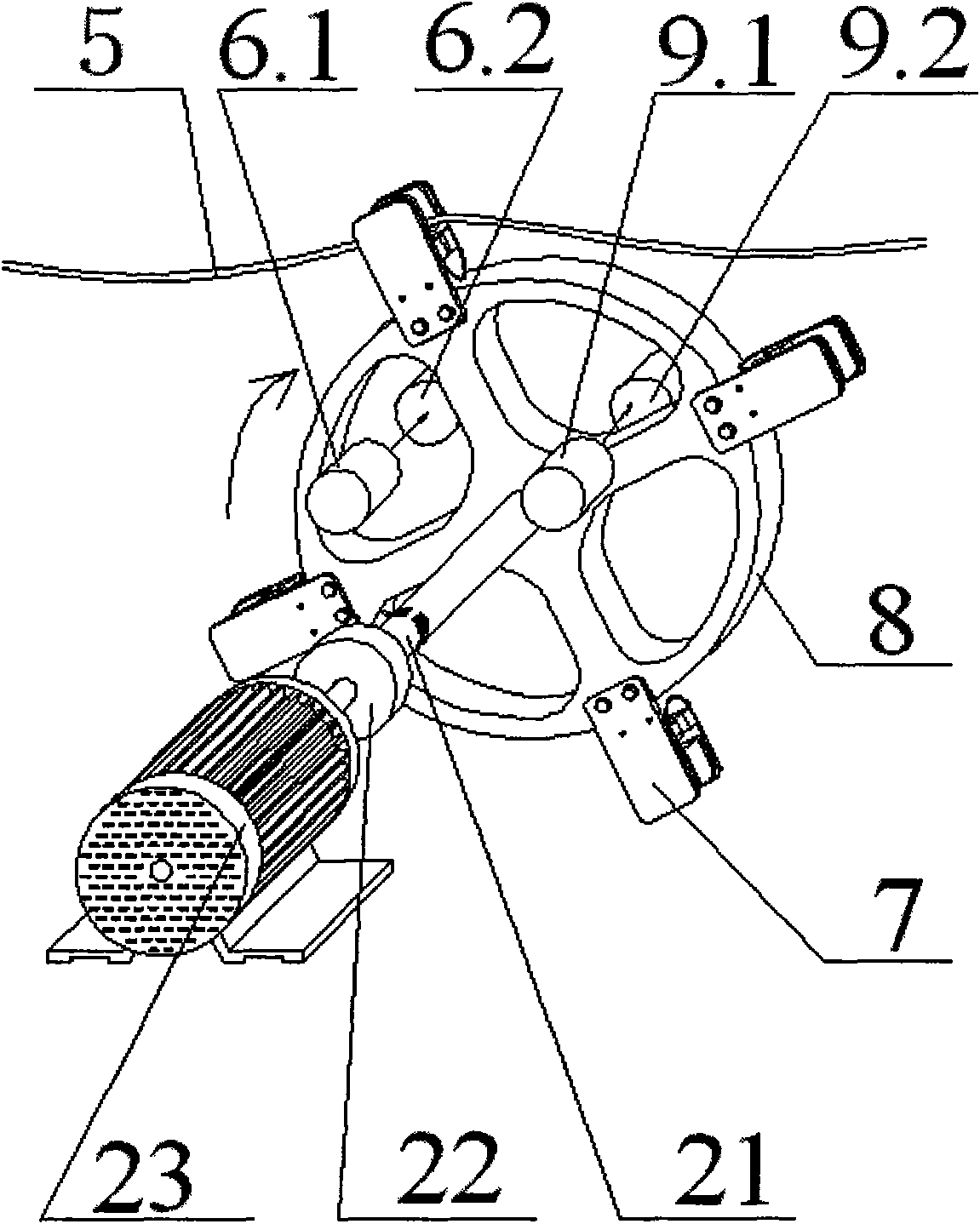

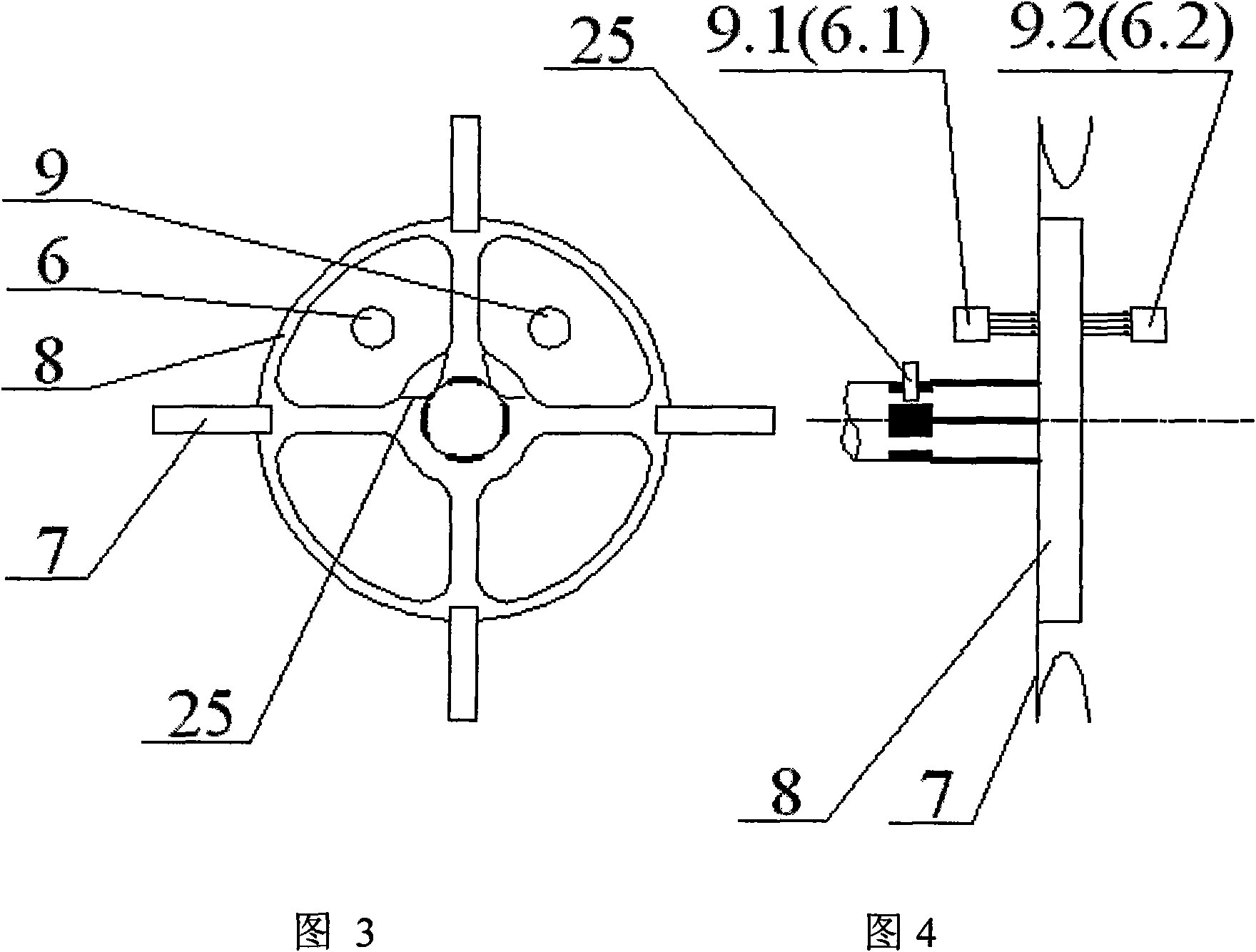

[0032] Such as figure 2 , image 3 , Figure 4 As shown, the grip wheel part: the hollow grip wheel 8 with cross-shaped spokes is installed on the third shaft 21, the third shaft 21 is connected with the third motor 23 through the second electromagnetic clutch 22, and the upper edge of the third shaft 21 The circumference is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com