High temperature high pressure enclosed counteraction apparatus and counteraction method thereof

A high-temperature, high-pressure, digestion device technology, applied in the preparation of test samples, etc., can solve the problems of limited application, poor airtight reliability of decompression devices, and high cost of digestion devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

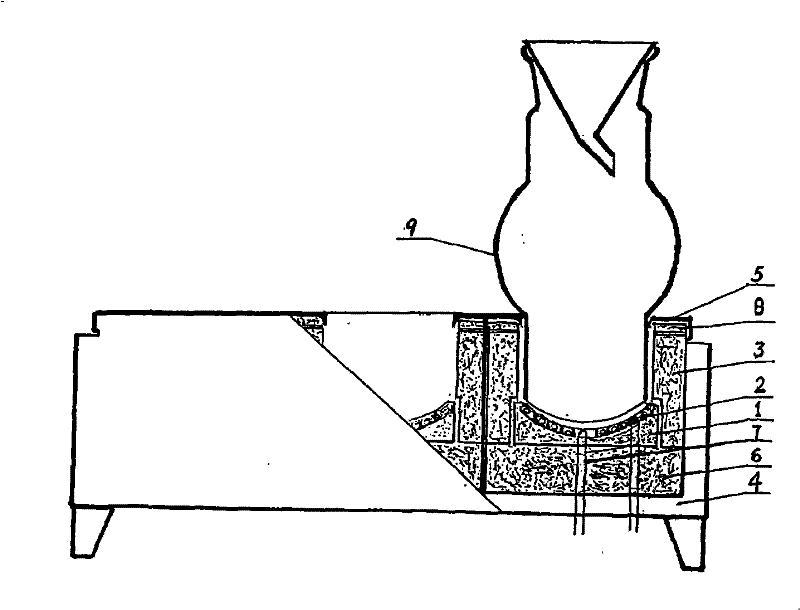

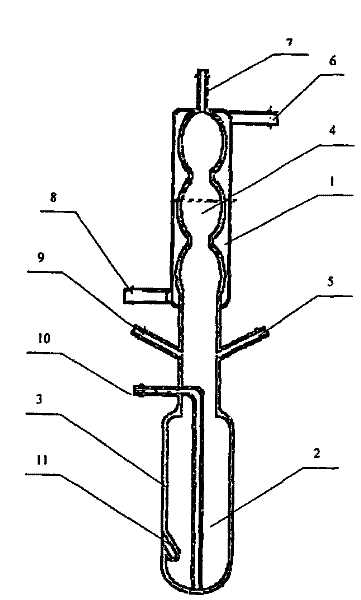

[0017] Figure 4 Shown are the front sectional view and the right view of the high temperature and high pressure airtight digestion device of the present invention, the left side is the front view, and the right side is the right view, wherein: 1 is the compression knob, 2 is the inner knob, 3 is the spring, 4 5 is the indenter, 5 is the fixed part, 6 is the guide rod, 7 is the upper high-voltage solenoid valve, 8 is the fixed support side plate, 9 is the temperature switch, 10 is the groove in the glass digestion tank, 11 is the glass wrapped with resistance heating wire Digestion tank, 12 is the lower high-pressure solenoid valve, and 13 is a transparent protective cover.

[0018] Figure 5 It is the top view of the high temperature and high pressure airtight digestion device of the present invention

[0019] The invention mainly includes two parts: a corrosion-resistant glass digestion tank and a combined high-pressure valve pressing and fixing mechanism. The combined hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com