A ceramic pin housing structure and manufacturing method thereof

A shell and ceramic technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as inability to assemble and weld, air tightness problems, and inability to fill solder, so as to improve air tightness. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

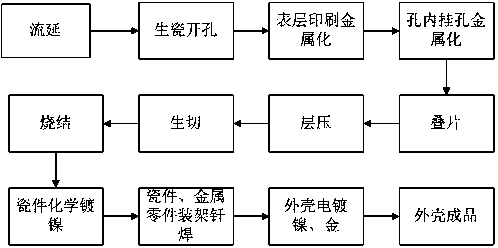

[0040] Manufacturing the ceramic pin shell structure includes the following steps:

[0041] 1) Using tape casting equipment at a drying temperature of 120°C to obtain a sheet of raw porcelain tape with a thickness of 0.34mm and a length and width of 210mm;

[0042] 2) Take 4 layers of 0.34 thick aluminum nitride raw porcelain tape, and use a mechanical punching machine to open the holes required for the lead pin;

[0043] 3) Use a printing machine and a screen screen to coat the top surface and the bottom surface with tungsten paste to obtain the metallized area required for the welding end seal of the ceramic part and the Kovar sealing ring and the metal required for welding with the Kovar frame chemical area, to dry;

[0044] 4) After drying, use the stencil screen and printing machine to open holes for the tungsten paste on the outermost layer of the porcelain tape to realize the metallization of the inner wall, and obtain the metallization area of the guide pin and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com