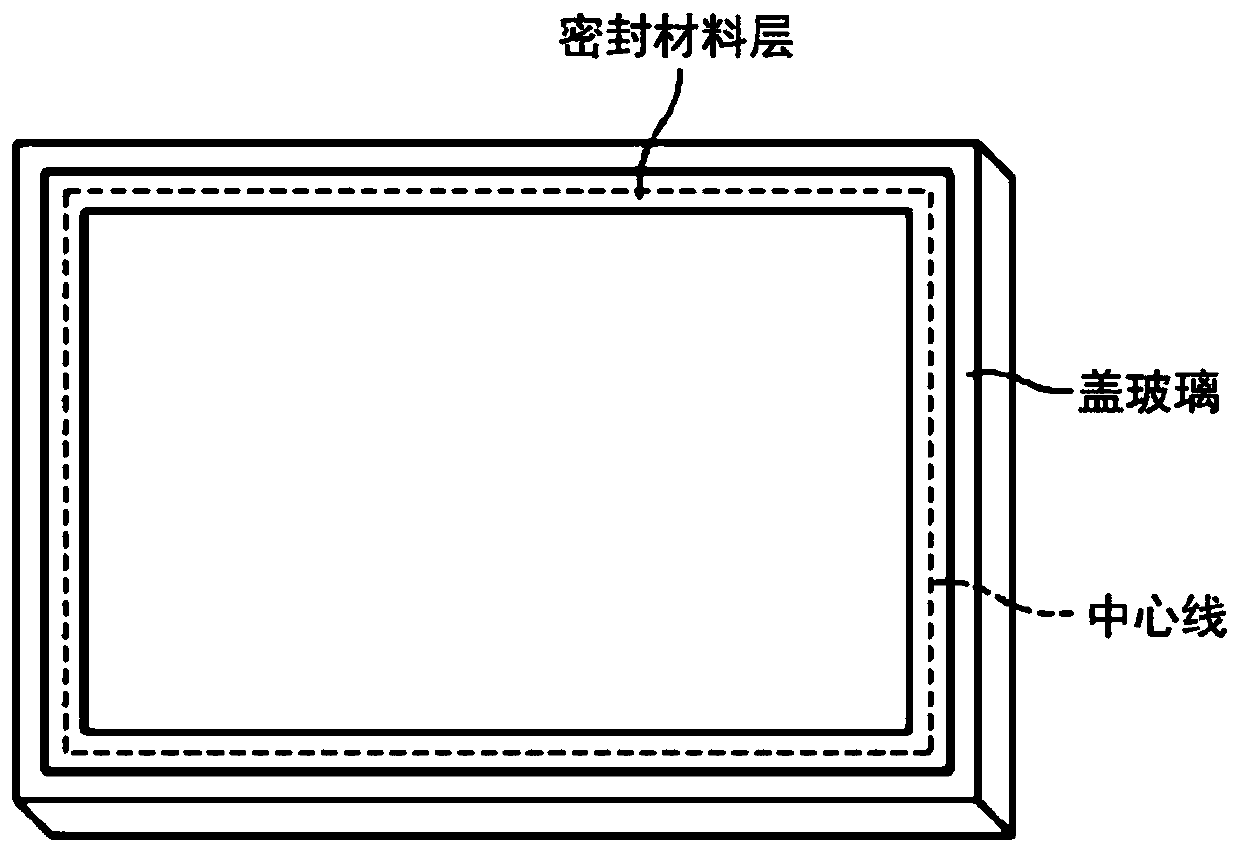

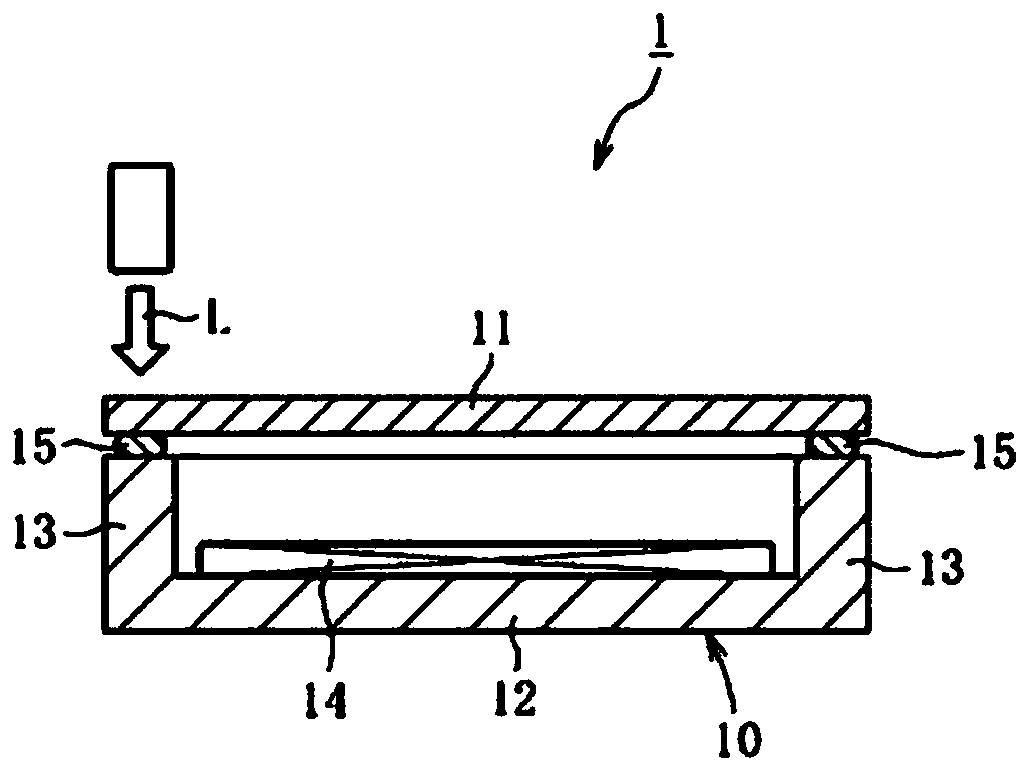

Cover glass and airtight package

A hermetic packaging, cover glass technology, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve problems such as thermal degradation of internal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, the present invention will be described based on examples. It should be noted that the following examples are merely examples. The present invention is not limited by the following examples.

[0082] Table 1 shows examples (sample Nos. 1 to 7) of the present invention. Table 2 shows comparative examples (sample Nos. 8 to 14).

[0083] [Table 1]

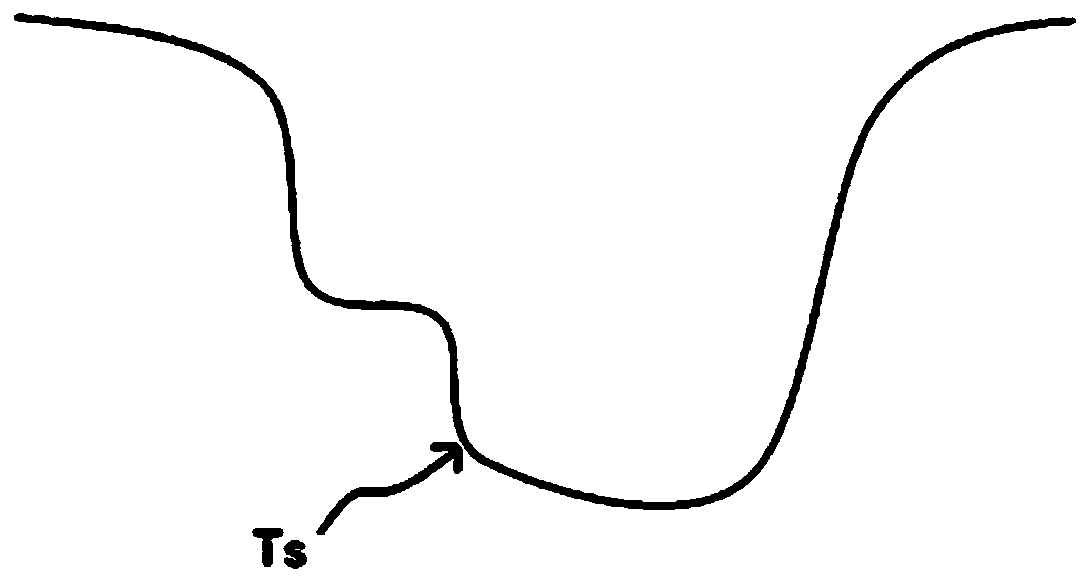

[0084] No.1 No.2 No.3 No.4 No.5 No.6 No.7 Center line length [mm] 172 114 88 64 44 24 172 Average width [mm] 0.50 0.40 0.35 0.30 0.30 0.25 0.55 Average width / centerline length [%] 0.29% 0.35% 0.40% 0.47% 0.68% 1.04% 0.32% Average thickness [μm] 0.6 0.6 0.6 0.6 0.6 0.6 0.6 air tightness ○ ○ ○ ○ ○ ○ ○

[0085] [Table 2]

[0086] No.8 No.9 No.10 No.11 No.12 No.13 No.14 Center line length [mm] 172 114 88 64 44 24 172 Average width [mm] 0.30 0.30 0.25 0.20 0.20 0.15 0.28 Averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com