A Large Size Ceramic Package Interface Structure

A technology of ceramic encapsulation and interface structure, applied in the direction of insulators, etc., can solve the problems such as the inability to effectively ensure the air-tightness of the large-sized vacuum insulation interface, the reduction of the vacuum performance of the vacuum insulation interface, and the large thermal expansion difference between the metal and the ceramic, etc. The effect of reducing the risk of explosion and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected", "fixed", etc.

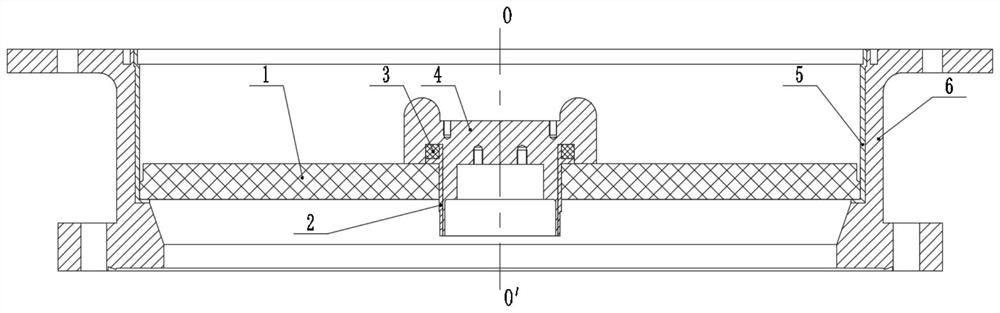

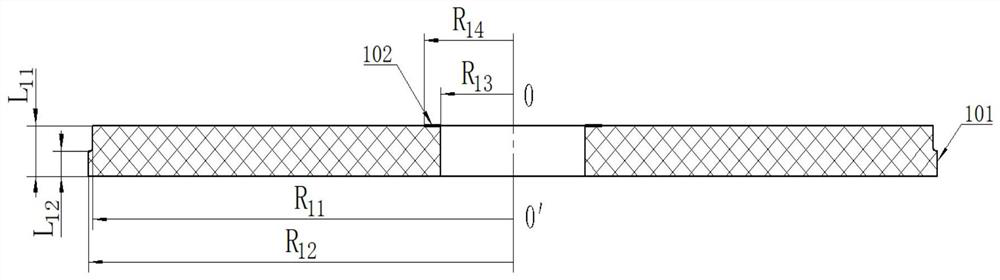

[0040] The present invention will be described in detail below.

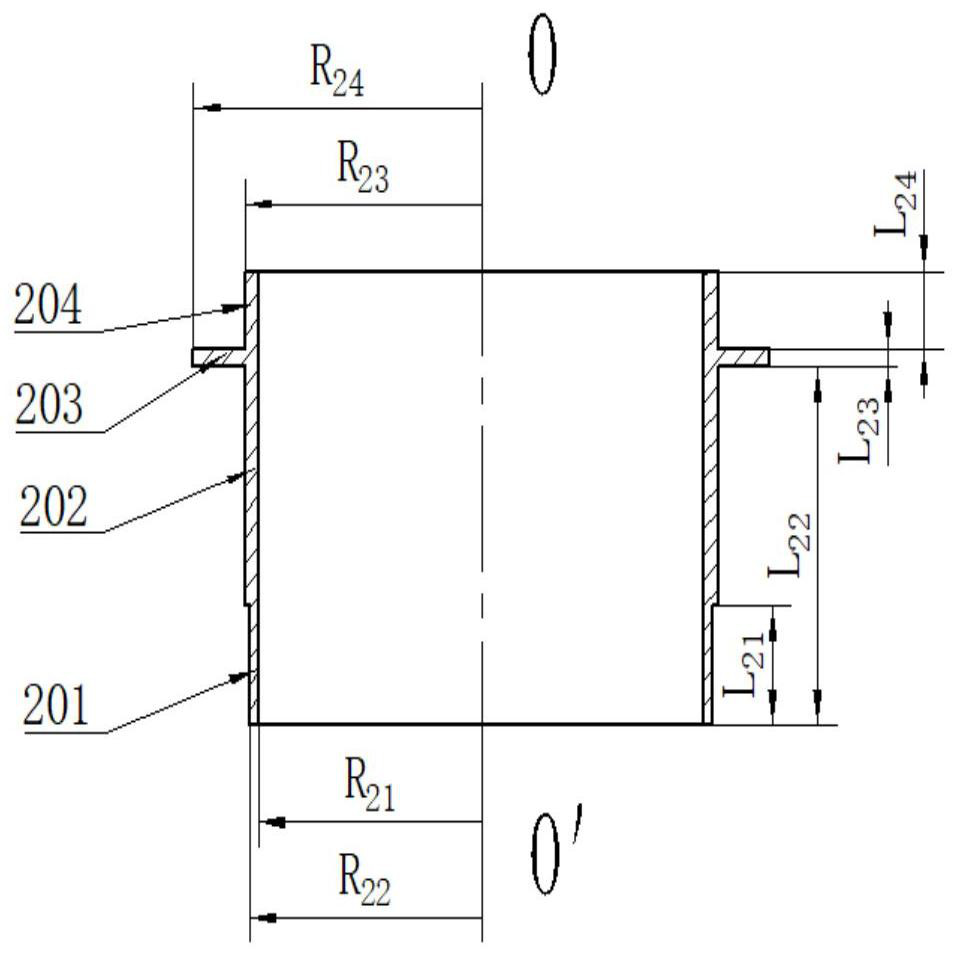

[0049] In some possible embodiments, the side of the cylinder one 401 away from the support ring is provided with an annular protrusion,

[0050] FIG. 4 is a schematic cross-sectional view of the inner conductor support base 4 of the present invention along the front direction of OO'. The inner conductor support seat 4 consists of a cylinder 401,

[0067] In some possible embodiments, in order to facilitate the installation and positioning of the ceramic during the brazing seal, and to facilitate

[0078] The present invention is not limited to the foregoing specific embodiments. The present invention extends to any of the

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com