Sheet-feed printer

A printing machine and single-page technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

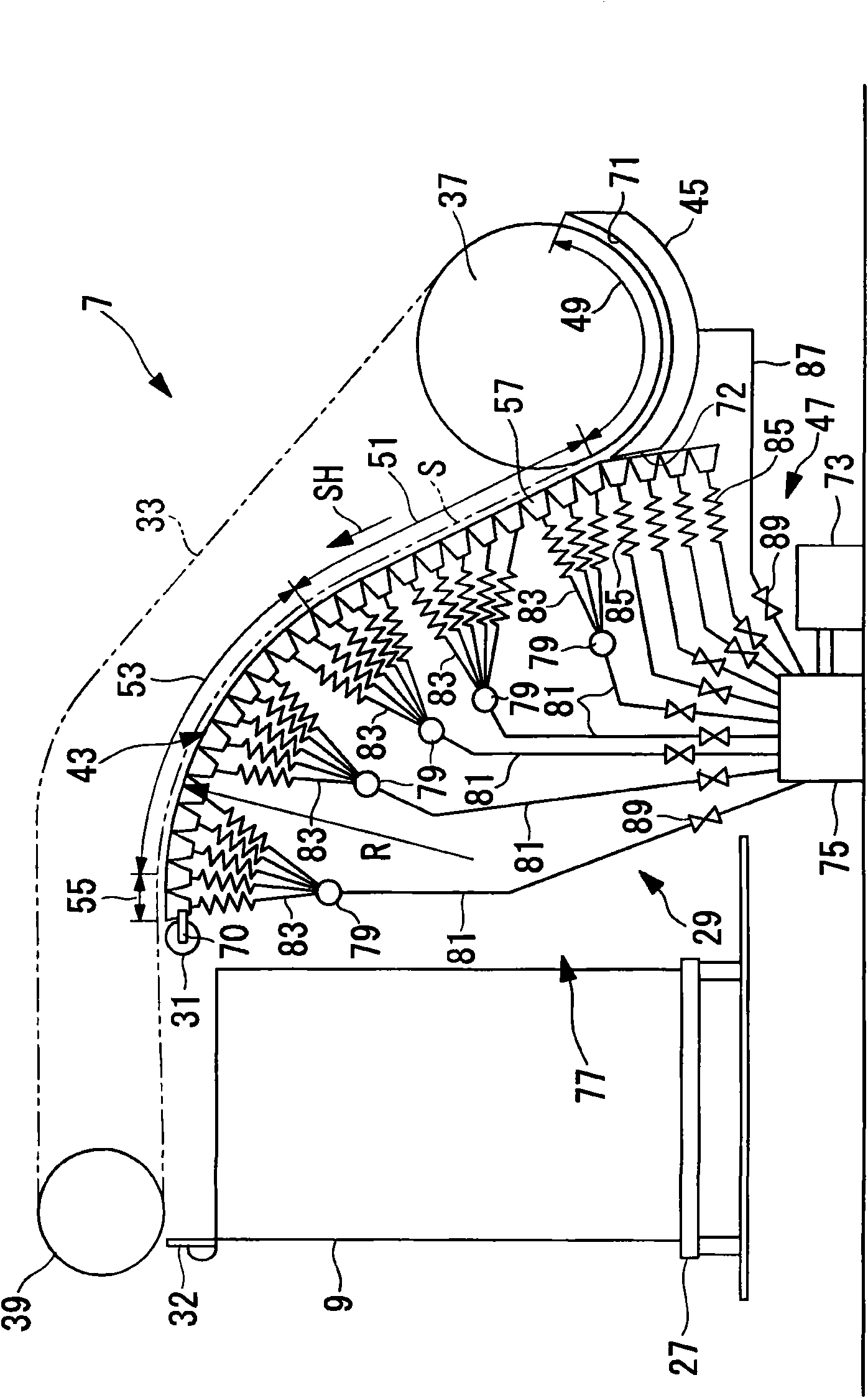

[0074] Use the following Figure 1 to Figure 7 A first embodiment of the present invention will be described.

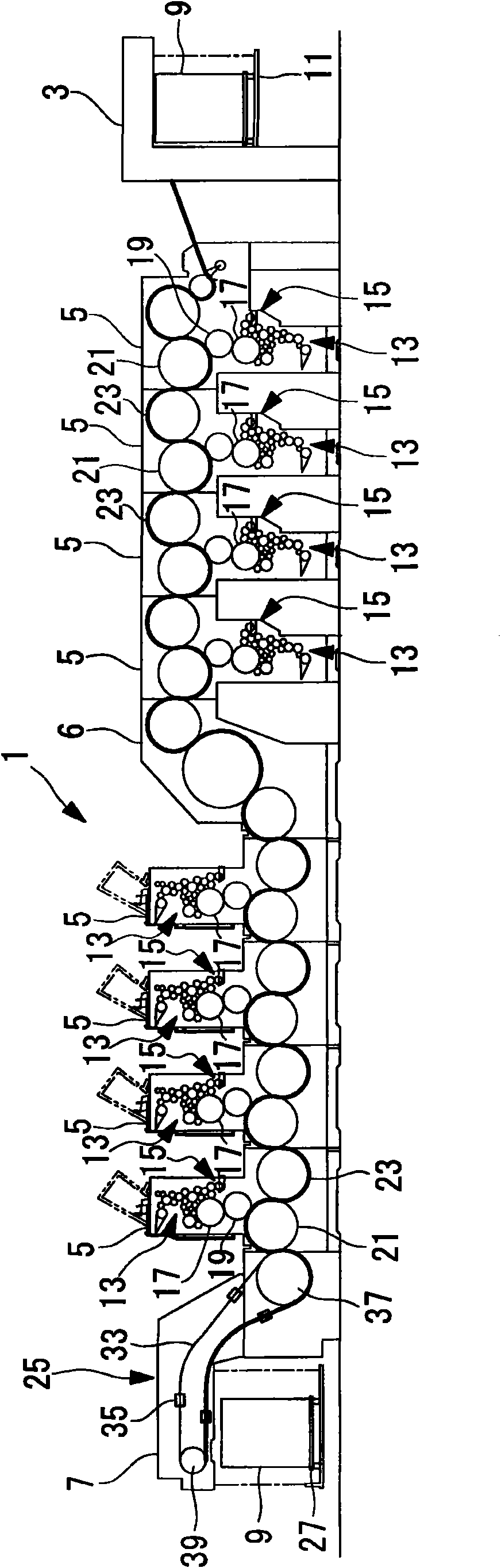

[0075] figure 1 It is a front view showing an overall schematic configuration of a double-sided printing machine (single-sheet printing machine) 1 .

[0076] The single-sheet double-sided printing machine 1 is equipped with: a sheet feeding device 3 that supplies the stacked single sheets from the upstream side to the downstream side of the single sheets that are supplied to the printed matter; for example, a plurality of printing units 5 that print different colors to realize color printing; The paper discharge device 7 where the single sheets are placed in a stacked state.

[0077] The paper feeding device 3 sequentially takes out and supplies the single sheets 9 stacked on the paper feeding table 11 one by one from the top using a paper feeding mechanism (sheet sucker, cam, etc.) not shown.

[0078] The paper feed table 11 moves upward in response to feeding of...

no. 2 example

[0181] Use below Figure 9 with Figure 10 A second embodiment of the present invention will be described.

[0182] The basic structure of this embodiment is the same as that of the first embodiment, but the structure of the cavity 57 is different. This difference will be described in this embodiment, and repeated descriptions of other parts will be omitted.

[0183] The same symbols are assigned to the same structural elements as those in the first embodiment, and detailed description thereof will be omitted.

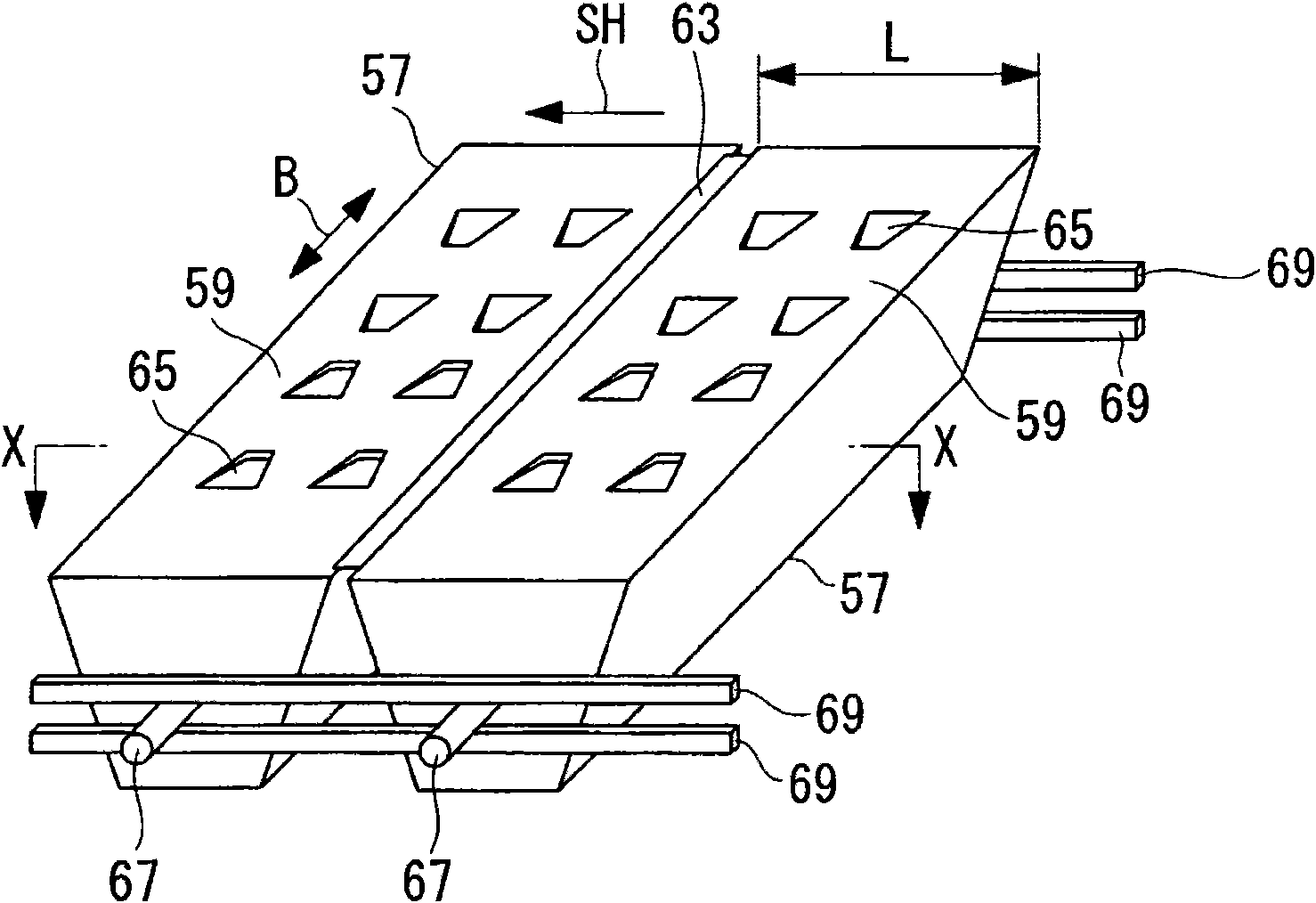

[0184] Figure 9 It is a front view showing a part of the moving sheet guide 43 . Figure 10 is a front view of cavity 58.

[0185] When the moving single-sheet guide 43 is moved in the single-sheet conveyance direction SH corresponding to the size of the single sheet 9, the moving single-sheet guide 43 has a cavity 58 that can be positioned at the convexly curved portion 53 and a cavity that cannot be positioned at the convexly curved portion 53. Cavity 57.

[...

no. 3 example

[0194] Use below Figure 11 A third embodiment of the present invention will be described.

[0195] The basic structure of this embodiment is the same as that of the first embodiment, but the structure of the cavity 57 is different. This difference will be described in this embodiment, and repeated descriptions of other parts will be omitted.

[0196]The same symbols are assigned to the same structural elements as those in the first embodiment, and detailed description thereof will be omitted.

[0197] Figure 11 It is a front view showing a part of the moving sheet guide 43 .

[0198] When the moving sheet guide 43 moves in the sheet conveyance direction SH corresponding to the size of the sheet 9, the upstream side portion of the moving sheet guide 43 has a cavity 56 that can be located at a part away from the sheet conveyance path S and It is impossible to locate the cavity 57 at the part away from the sheet conveyance path S. As shown in FIG.

[0199] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com