Headbox and stock delivery system for a papermaking machine

A technology of headbox and paper machine, which is applied in the direction of paper machine, paper making, paper machine wet end, etc., and can solve the problem that the pulp flow cannot evenly cross the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Certain terms used in the ensuing descriptions are for convenience only and are not to be considered as limitations, wherein the words "lower" and "upper" refer to directions in the drawings for reference, and "CD" generally is the cross-direction of the equipment extending across the moving Fourdrinier paper machine fabric used to receive the stock, while "MD" means the machine direction, or movement in the paper machine The forward direction of the belt, and the terms "pipes", "tube", and "hoses" are used interchangeably herein to refer to elongated hollow bodies used to carry fluids, and It may then be flexible or rigid, and the terms "a" and "an" are defined to include one or more of the indicated item unless otherwise indicated.

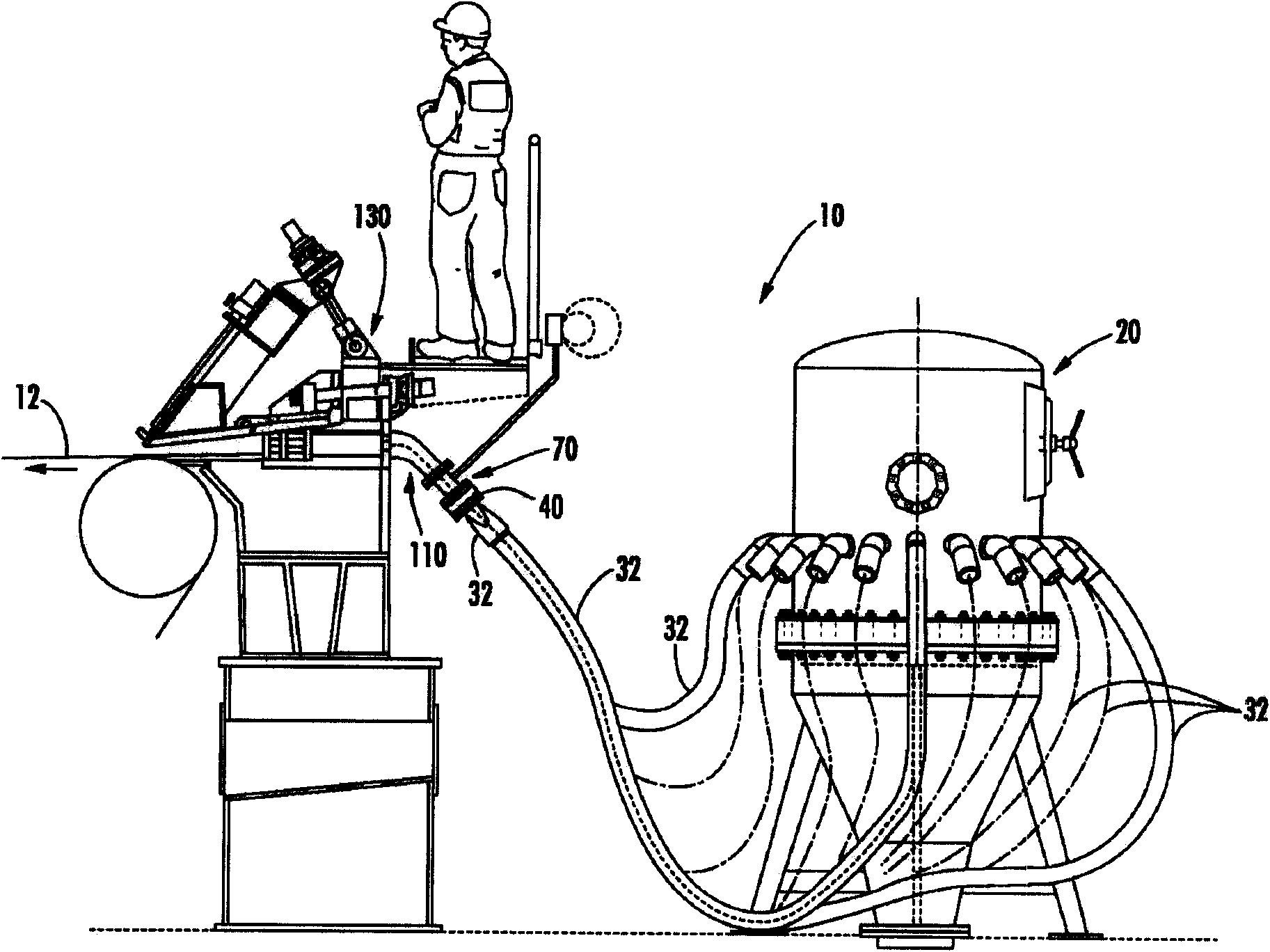

[0037] Such as figure 1 Shown is the headbox and stock delivery system 10 for a paper machine. The headbox and slurry delivery system 10 includes a radial distributor 20, a stock dilution assembly 70, a diverging channel 110, and a head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com