Two-stage drive shaft device

A technology of drive shaft and sliding device, which is applied in the direction of control device, transportation and packaging, vehicle parts, etc., can solve the problems of vehicle wheel elevation, hidden danger, insufficient slip margin, etc. The effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

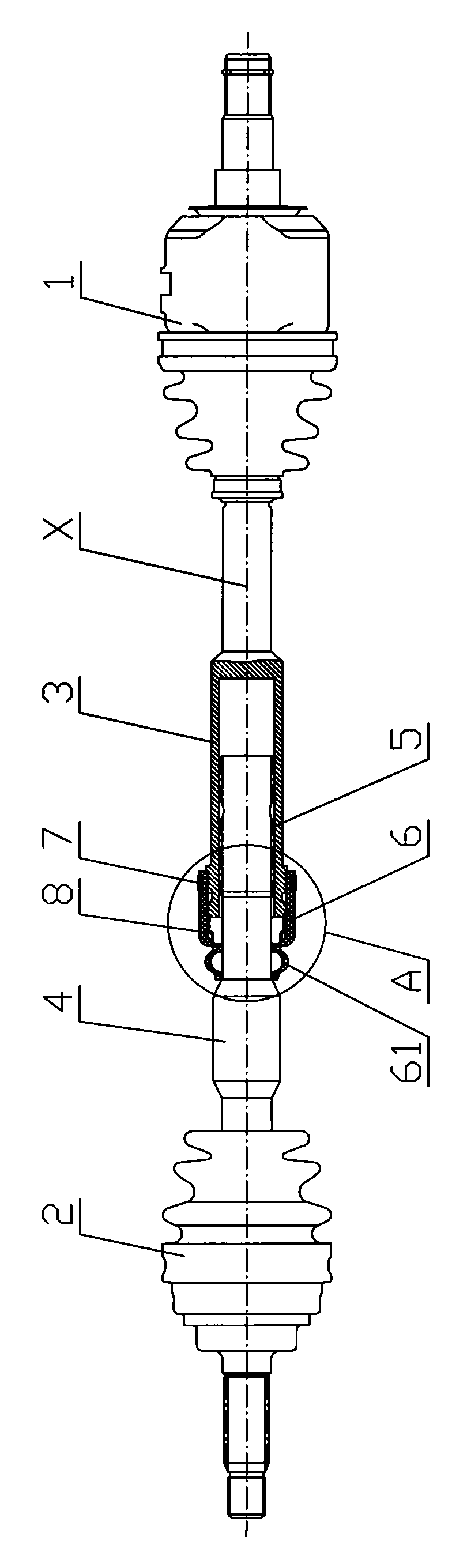

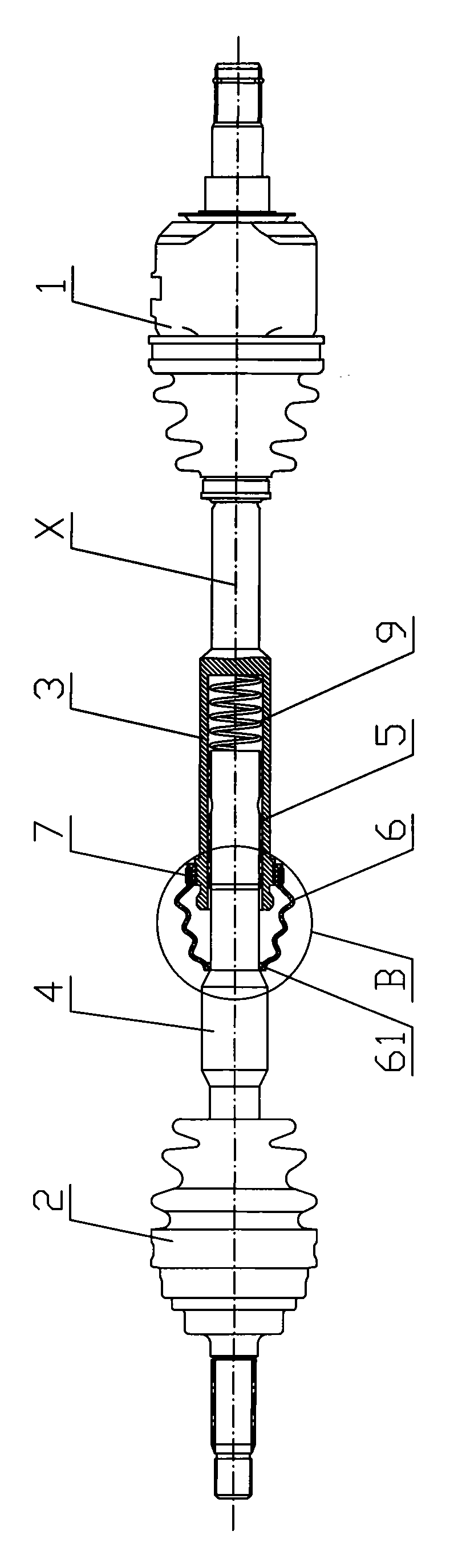

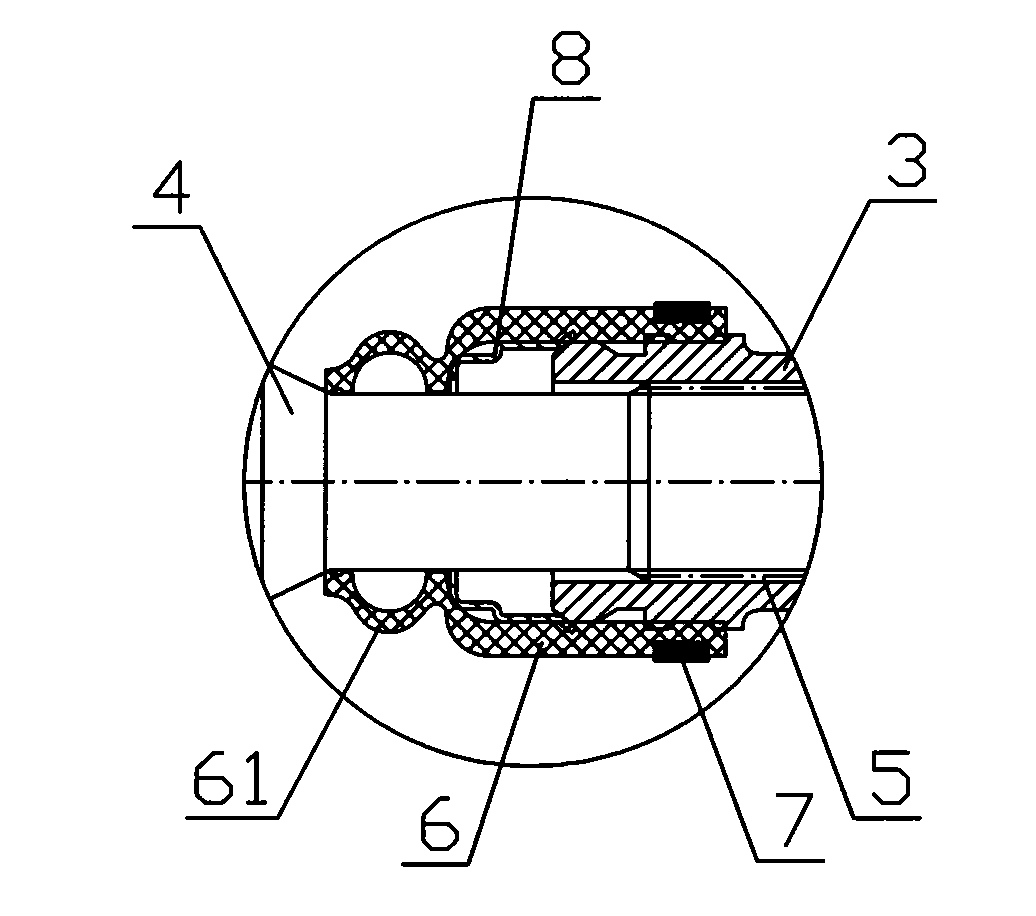

[0027] The invention discloses a two-stage drive shaft device, such as figure 1 and image 3 The first embodiment shown includes a sliding joint 1 whose shaft is connected to the transmission and a fixed joint 2 whose shaft is connected to the wheel hub. Both the sliding joint 1 and the fixed joint 2 adopt the constant velocity universal joint of the prior art Yes, that is, the sliding joint itself can slide and expand along its axial direction X to compensate for changes in the axial length of the drive shaft.

[0028] The improvement point of the present invention is that, instead of the rigid connection between the sliding joint 1 and the fixed joint 2 in the prior art, a two-stage joint for adjusting the relative axial distance between the sliding joint and the fixed joint is provided. Auxiliary slide.

[0029] Specific reference figure 1 and image 3 As shown, the secondary auxiliary sliding device includes a shaft sleeve 3 fixed at one end of the sliding joint 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com