Frame structure, backlight module and display module

A frame structure, backlight module technology, applied in optics, light source fixing, nonlinear optics, etc., can solve the problems of increasing production cost and time, degumming, etc., and achieve the effect of good display quality, reduced light leakage, and good light output effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

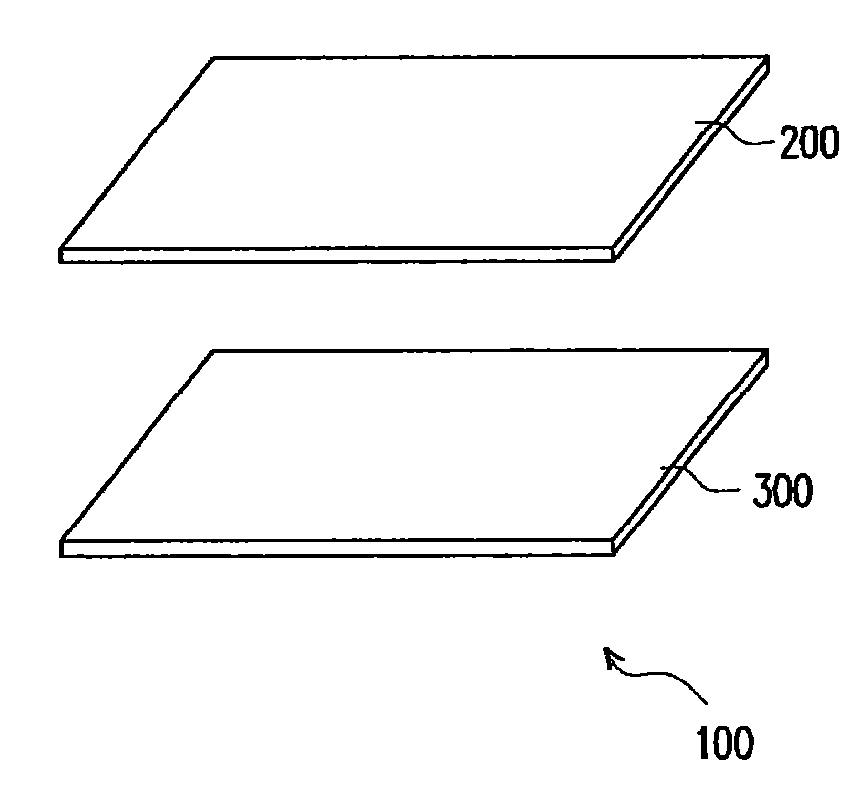

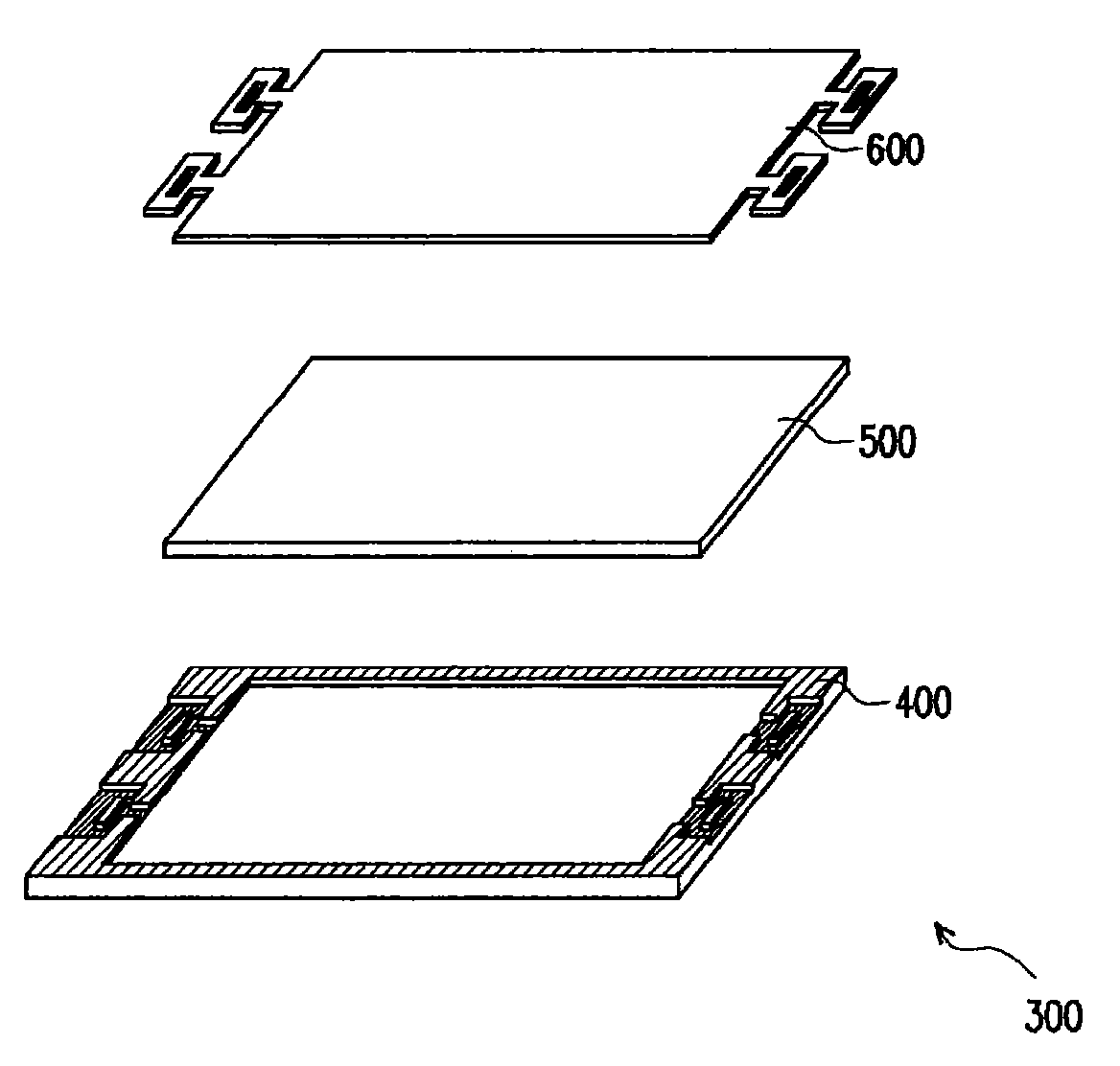

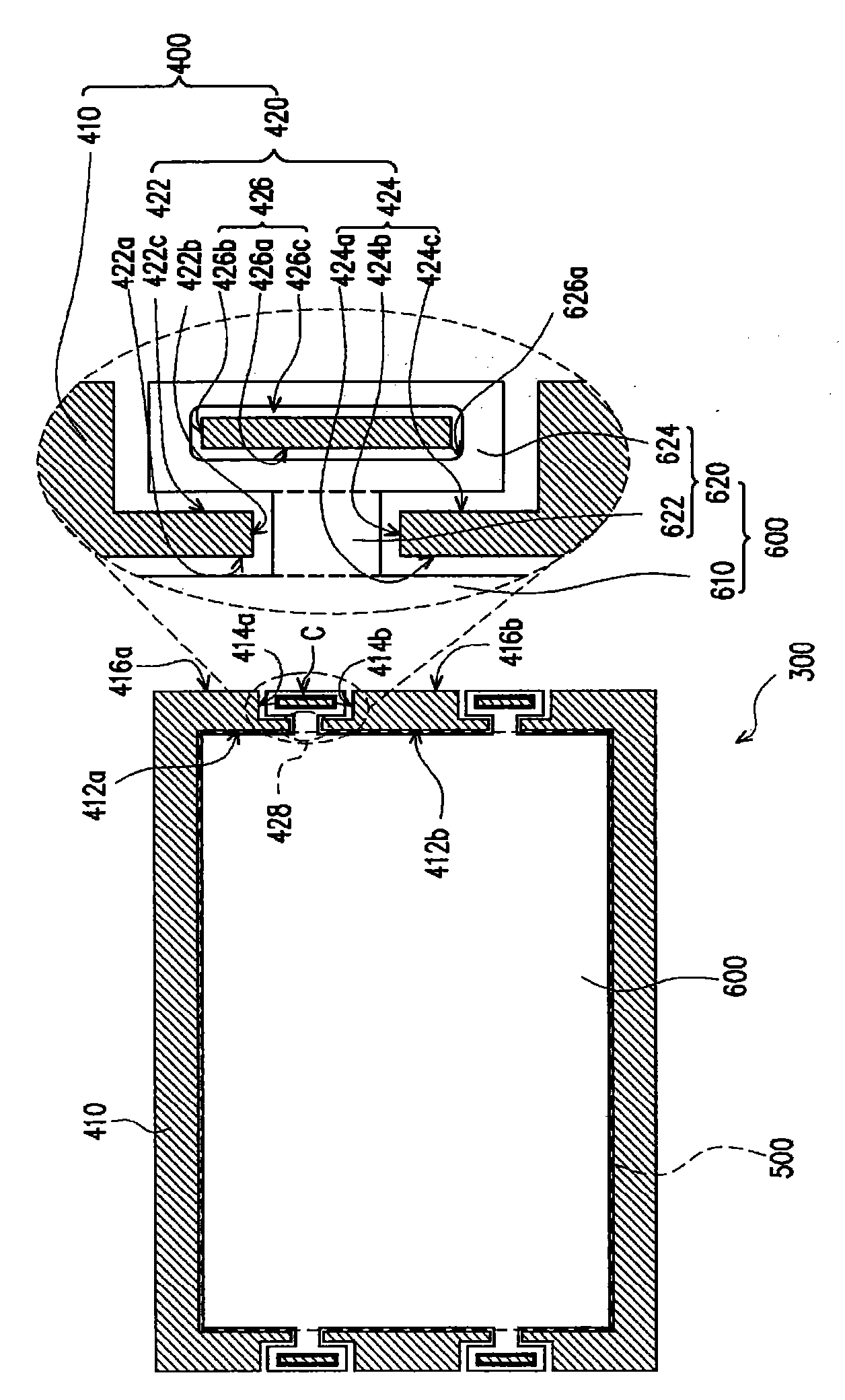

[0057] figure 1 is a schematic diagram of a display module according to an embodiment of the present invention, figure 2 for figure 1 An exploded schematic diagram of the backlight module of the display module, image 3 for figure 1 A schematic diagram of the combination of the display module and the backlight module. Please also refer to figure 1 , figure 2 and image 3 The display module 100 includes a display panel 200 and a backlight module 300 , wherein the backlight module 300 is disposed on one side of the display panel 200 , for example, is located below the display panel 200 . The backlight module 300 includes a frame structure 400, a light source module 500 and an optical film 600, wherein the light source module 500 is located in the frame structure 400 to provide brightness for the display panel 200 to display images, and the optical film 600 is located in the frame structure 400 Inside and above the light source module 500, it may include a prism sheet, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com