Semiconductor lead heading machine

A technology for semiconductors and heading machines, which is applied in semiconductor/solid-state device manufacturing, circuit/current collector parts, metal extrusion, etc. It can solve problems such as low precision, burrs, rough surfaces, etc., to improve precision and improve production efficiency , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

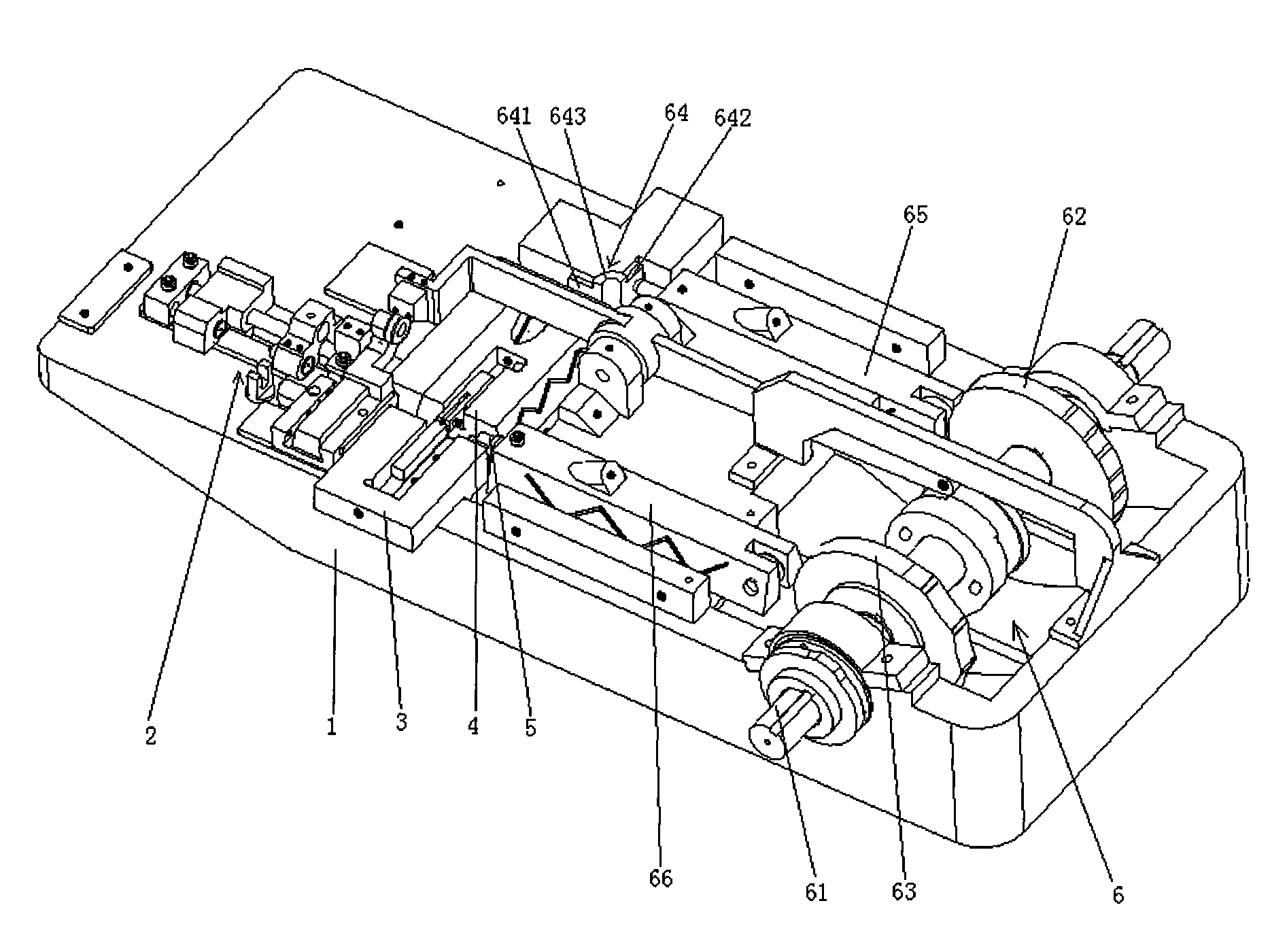

[0011] Such as figure 1 As shown, the semiconductor wire heading machine includes a machine platform 1, and a wire feeding mechanism 2, a front mold 3, a rear mold 4, a bumper 5, and a pushing mechanism 6 arranged on the machine platform 1. The front and rear molds 3 , 4 can be combined to form a mold cavity, the front and rear molds 3 and 4 lock the wire blank sent by the wire feeding mechanism 2 into the mold cavity, and the pushing mechanism 6 pushes the bumper 5 to hit one end of the wire blank to form the end. The pushing structure described above includes a main shaft 61 driven by a motor, a clamping cam 62 rotating with the main shaft 61, a bumper cam 63, a transmission member 64, a mold clamping slider 65 and a bumper slider 66, and the transmission member 64 Rotate and fix on the machine table 1, the mold locking slider 65 is in close contact with the mold locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com