Glass substrate packaging system, protecting-sheet loading device, protecting-sheet feeding device, and glass substrate packaging method

A technology of glass substrates and loading devices, which is applied in the directions of packaging, transportation and packaging, and types of packaged items, and can solve problems such as glass substrate damage or increased size in the stacking direction, position deviation, or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, embodiments of the present invention will be described based on the drawings.

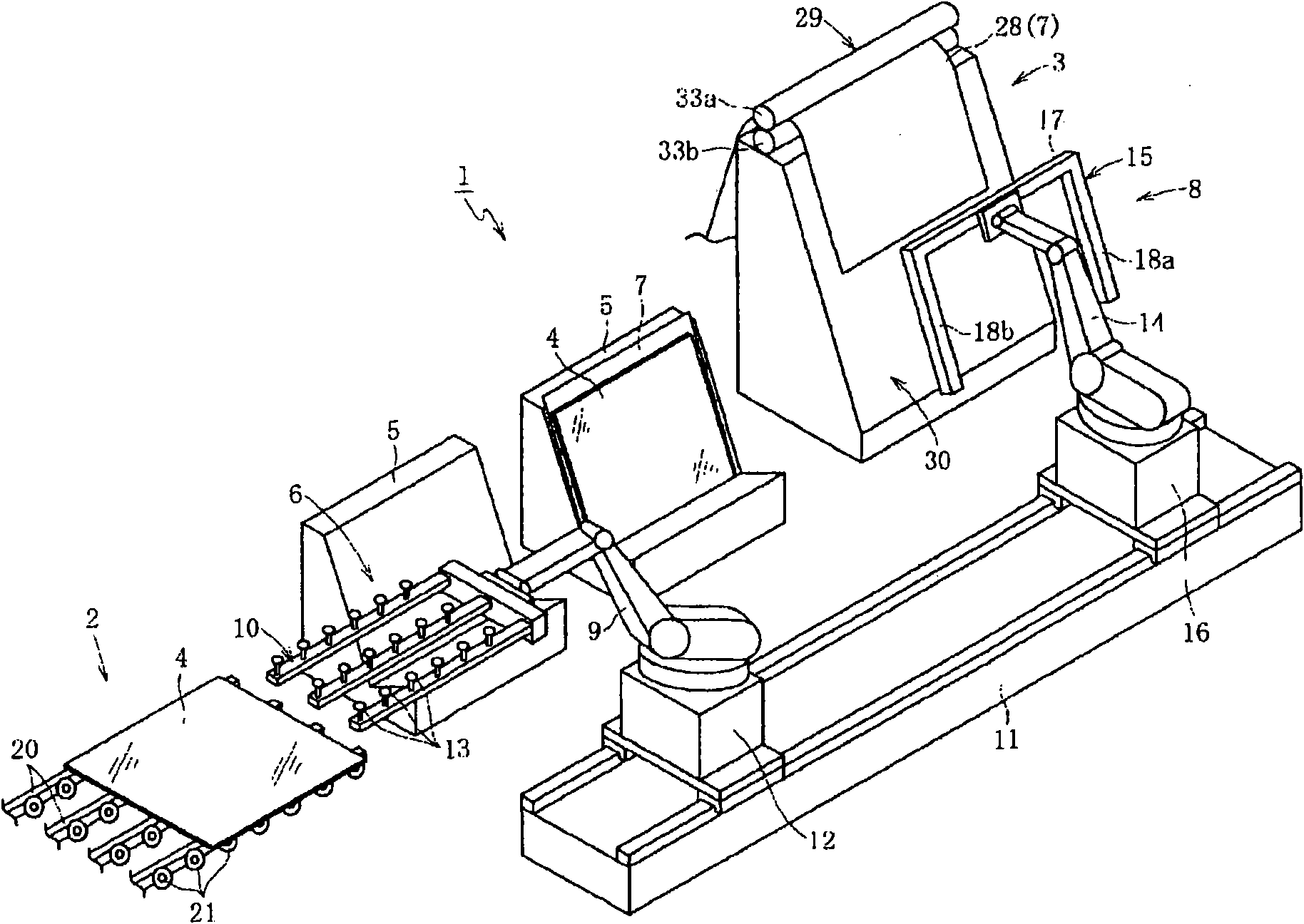

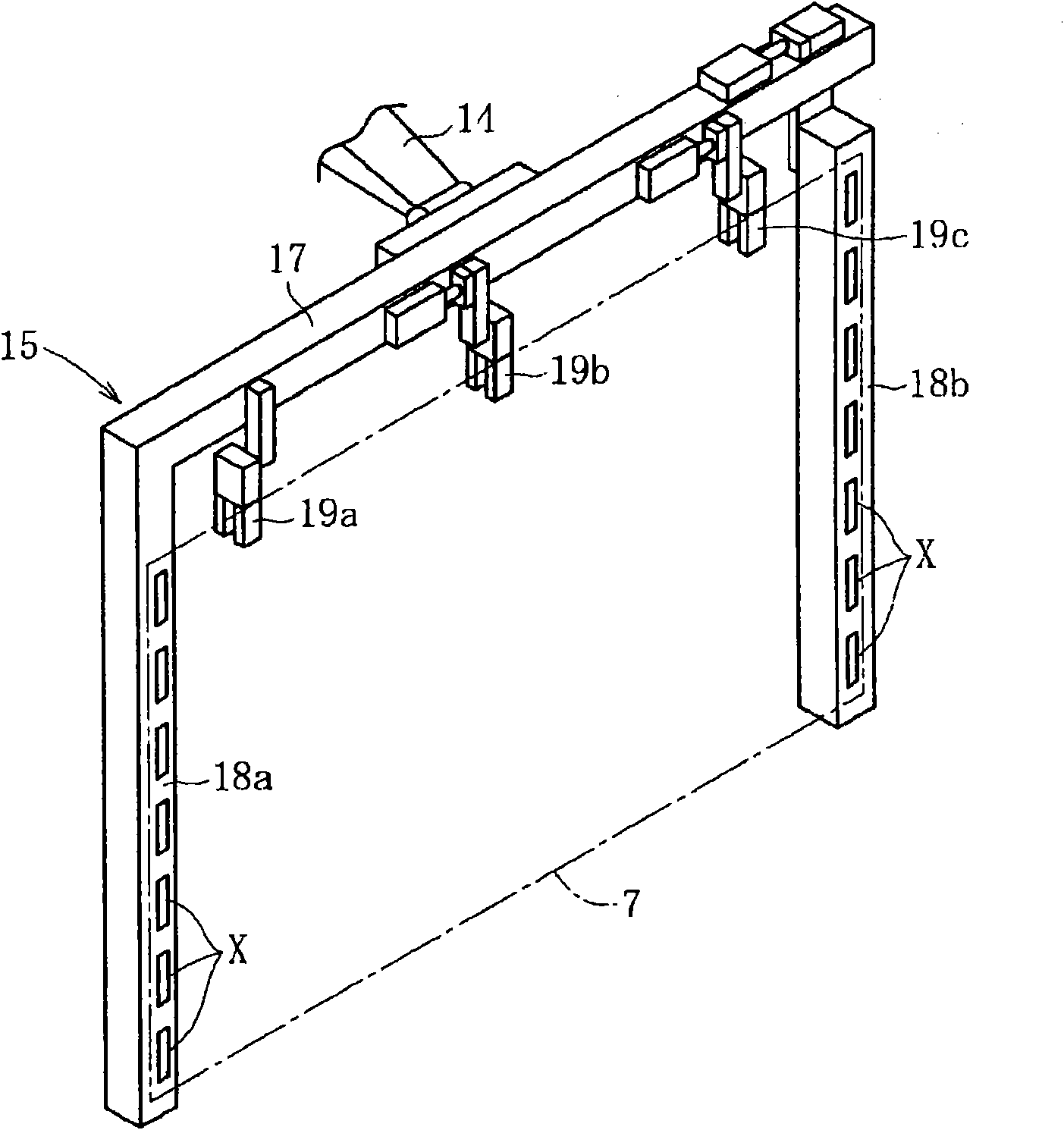

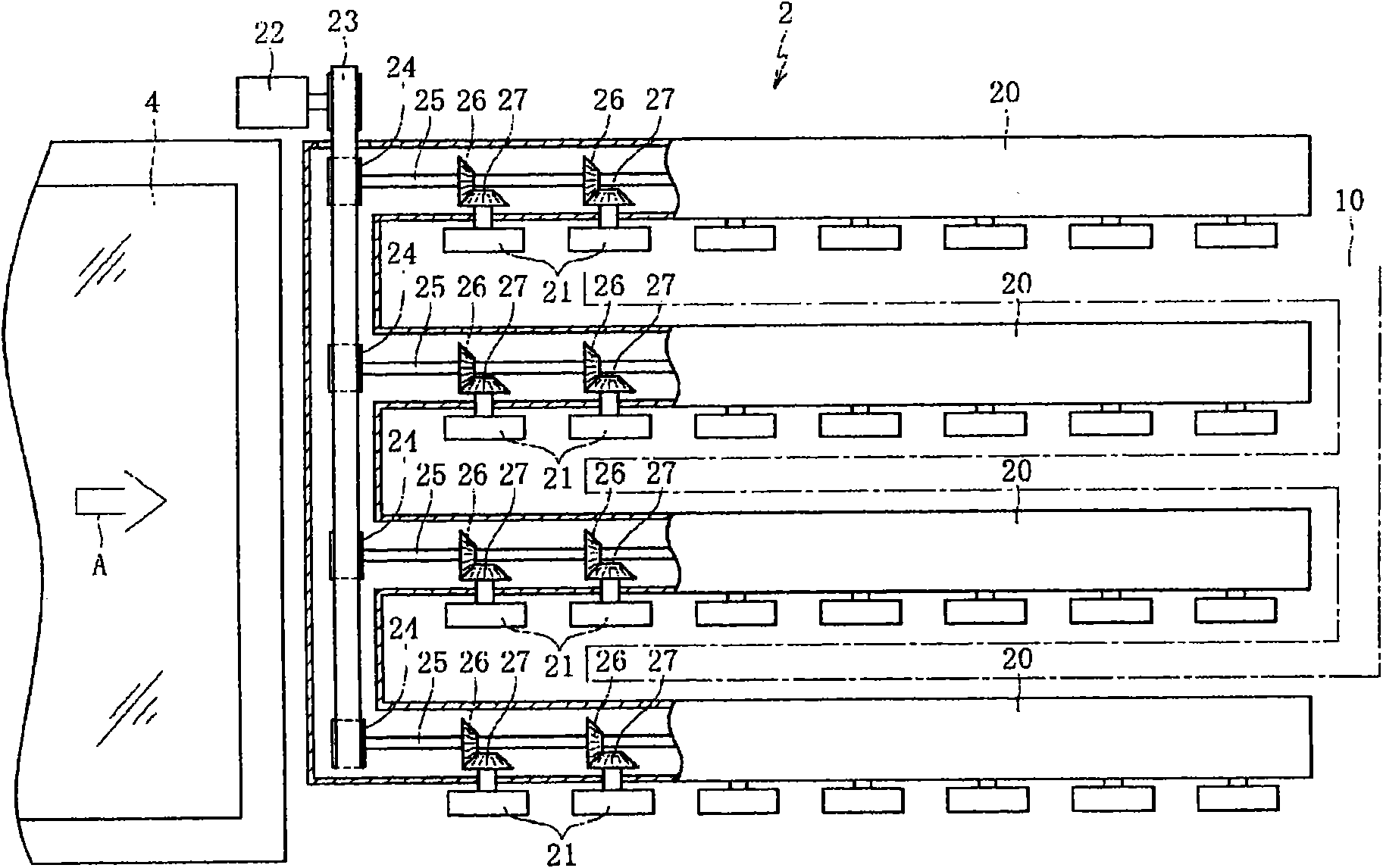

[0092] figure 1 It is a perspective view which schematically shows the whole structure of the glass substrate packing system which concerns on one Embodiment of this invention. As shown in the figure, the glass substrate packaging system 1 includes: a glass substrate supply device 2; a protective sheet supply device 3; Glass substrate loading device 6; the protective sheet 7 supplied by the protective sheet supply device 3 is placed on the protective sheet loading device 8 of the pallet 5, and the glass substrate loading device 6 and the protective sheet loading device 8 are used to place the protective sheet 7 on the pallet 5 respectively. The glass substrate 4 and the protective sheet 7 are automatically laminated and packaged alternately in the vertical orientation. In addition, in this embodiment, the glass substrate 4 is a glass substrate for FPD, and the size of one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com