Steel sheet for cans, hot-rolled steel sheet to be used as the base metal and processes for production of both

A manufacturing method and steel sheet technology, which are applied in the field of manufacturing steel sheets for cans and hot-rolled steel sheets for their base materials, can solve the problems of increased manufacturing processes, poor workability of DR materials, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

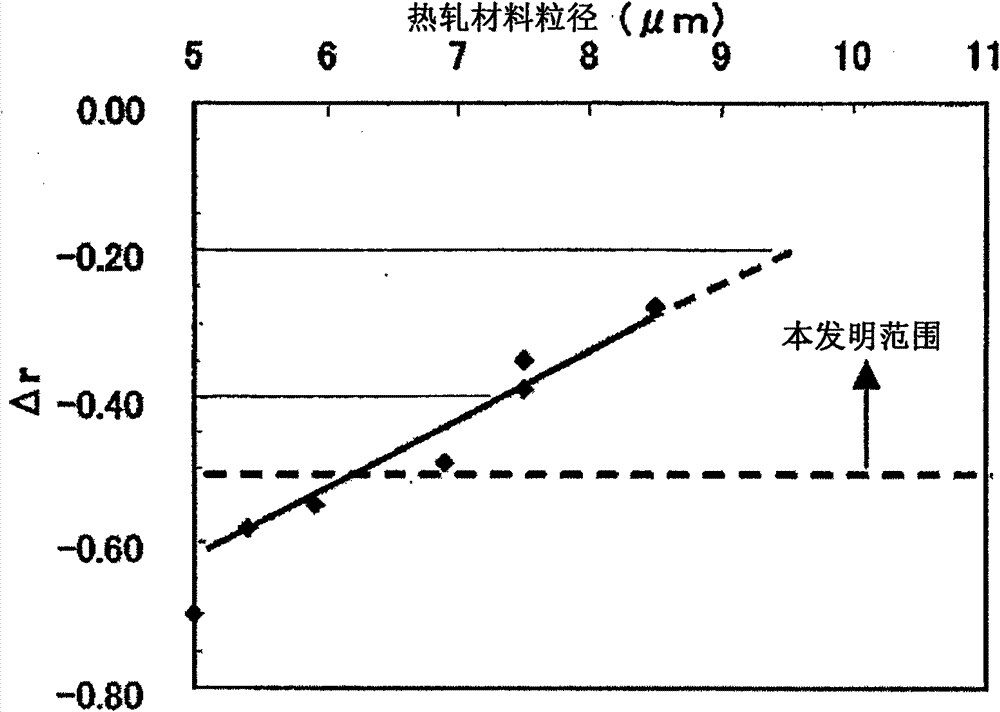

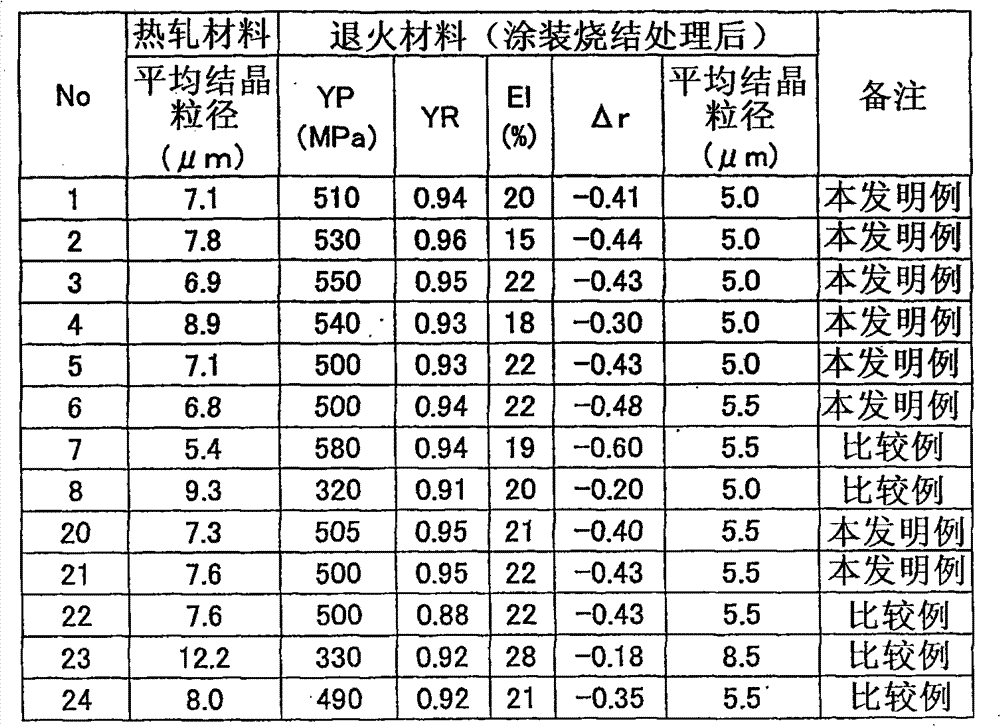

[0116] A steel containing the composition shown in Table 1 with the balance consisting of Fe and unavoidable impurities was smelted in a converter to obtain a billet. After reheating the obtained steel slab at 1250 degreeC, hot rolling was started. Hot rolling is carried out at a finishing temperature of 880°C to 900°C, cooled at an average cooling rate of 20°C to 40°C / s before coiling, and coiled at a coiling temperature of 620°C to 700°C. Next, after pickling, cold rolling is performed at a rolling reduction of about 90 to 94%, to manufacture a thin steel sheet of 0.17 to 0.2 mm. The obtained thin steel sheet was heated to 690 to 750° C. at a heating rate of 15° C. / second, and continuous annealing was performed at 690 to 750° C. for 20 seconds. Next, after cooling, temper rolling is performed so that the rolling ratio (measured by elongation) becomes 1.5% or less, and normal chrome plating (electroplating) is continuously performed to obtain a non-tin-plated steel sheet. I...

Embodiment 2

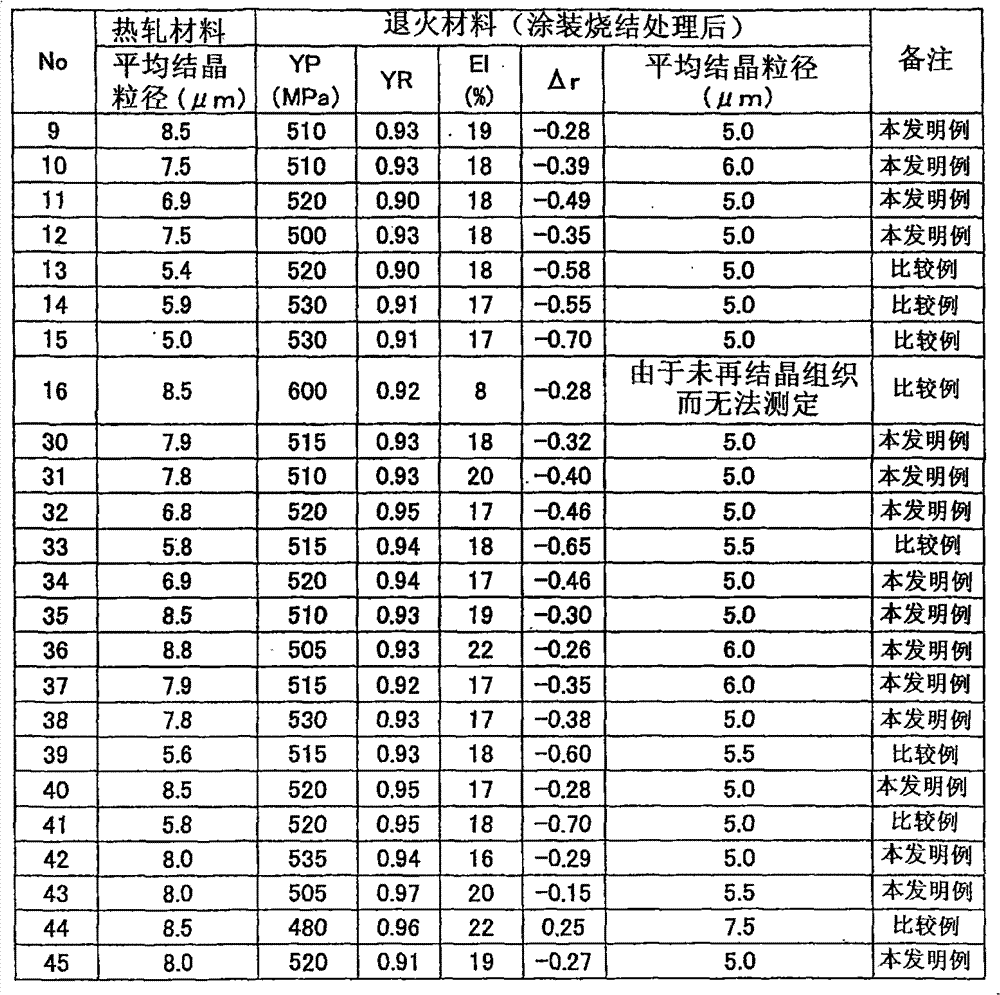

[0132] A steel containing the composition shown in Table 3 (same as No. 1 of Example 1) and the balance consisting of Fe and unavoidable impurities was melted in a real machine converter to obtain a billet. After reheating the obtained steel slab at 1250 degreeC, hot rolling was started. Hot rolling is carried out at a finishing temperature of 830°C to 900°C, cooled at an average cooling rate of 16°C to 45°C / s before coiling, and coiled at a coiling temperature of 580°C to 720°C. Next, cold rolling is performed at a rolling reduction of 75 to 94%, to produce a thin steel plate of 0.15 to 0.18 mm. The obtained thin steel sheet was heated to 630-740° C. at a heating rate of 20° C. / second, and continuous annealing was performed at 630-740° C. for 20-30 seconds. Next, after cooling, temper rolling was performed so that the rolling ratio was 1.5% or less, and normal chrome plating was continuously performed to obtain a non-tin-plated steel sheet. The detailed manufacturing condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com