Method for manufacturing rice transplanting seat

A production method and technology of a seat body, which are applied in the field of production of rice transplanting seats, and can solve problems such as troublesome production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

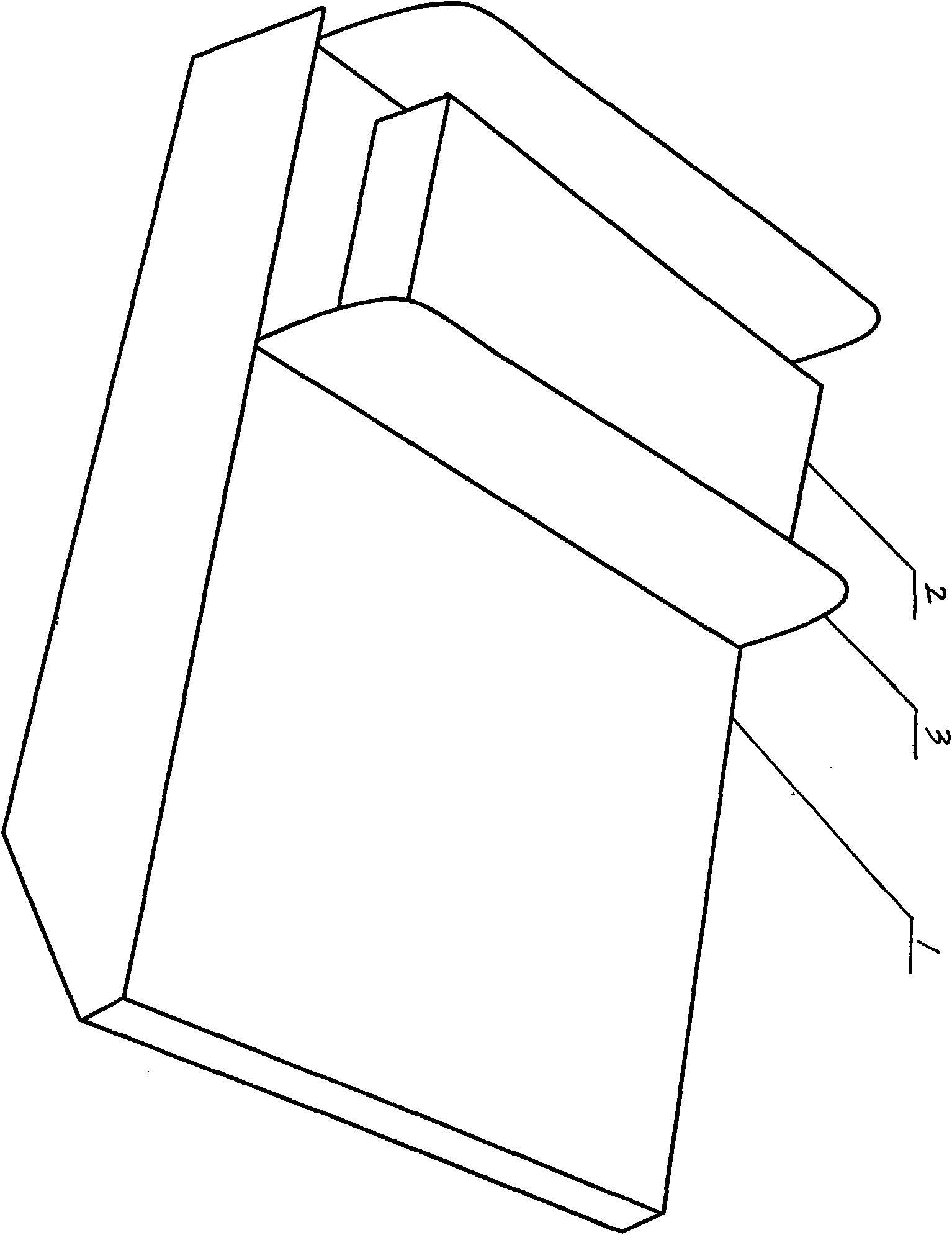

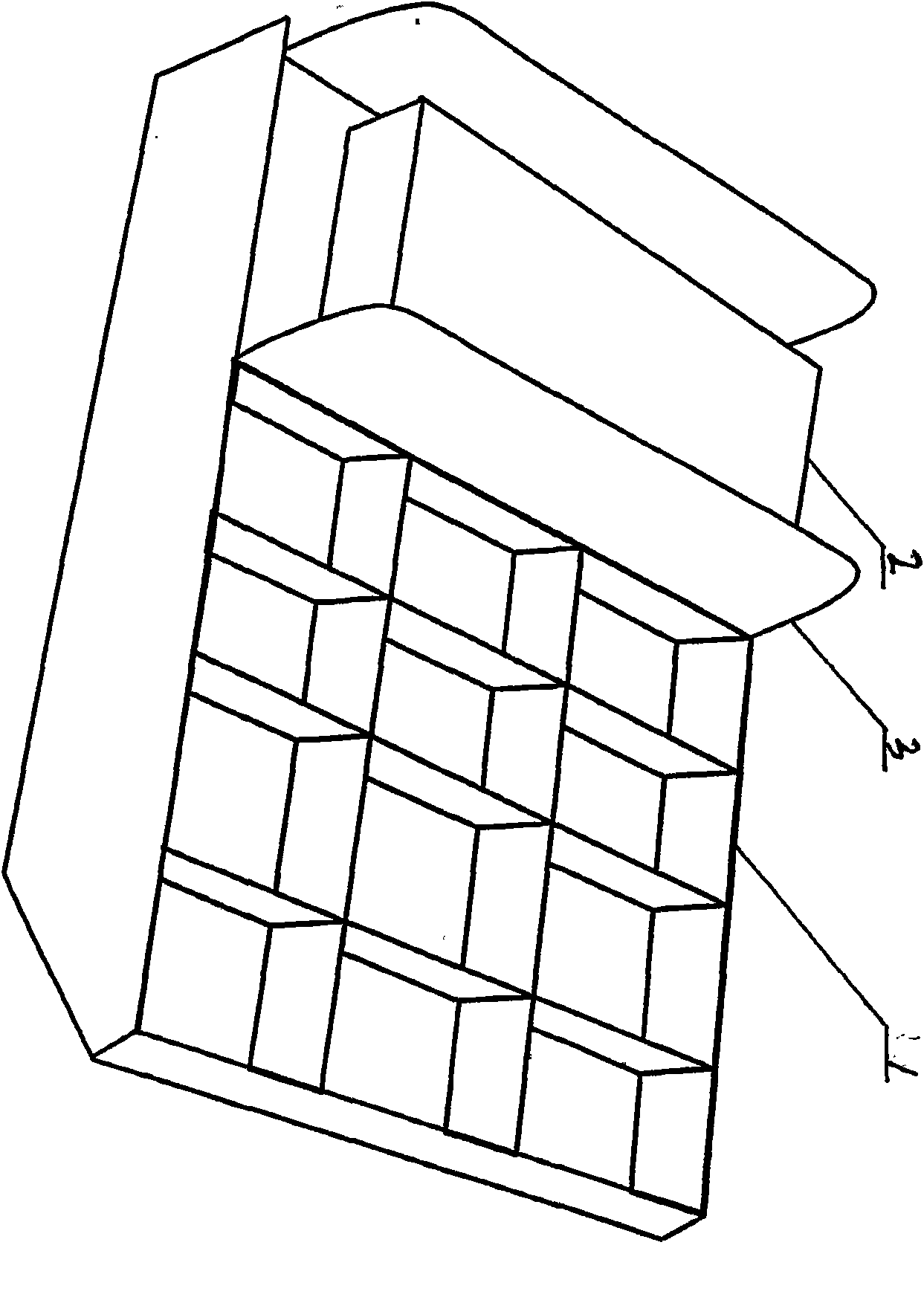

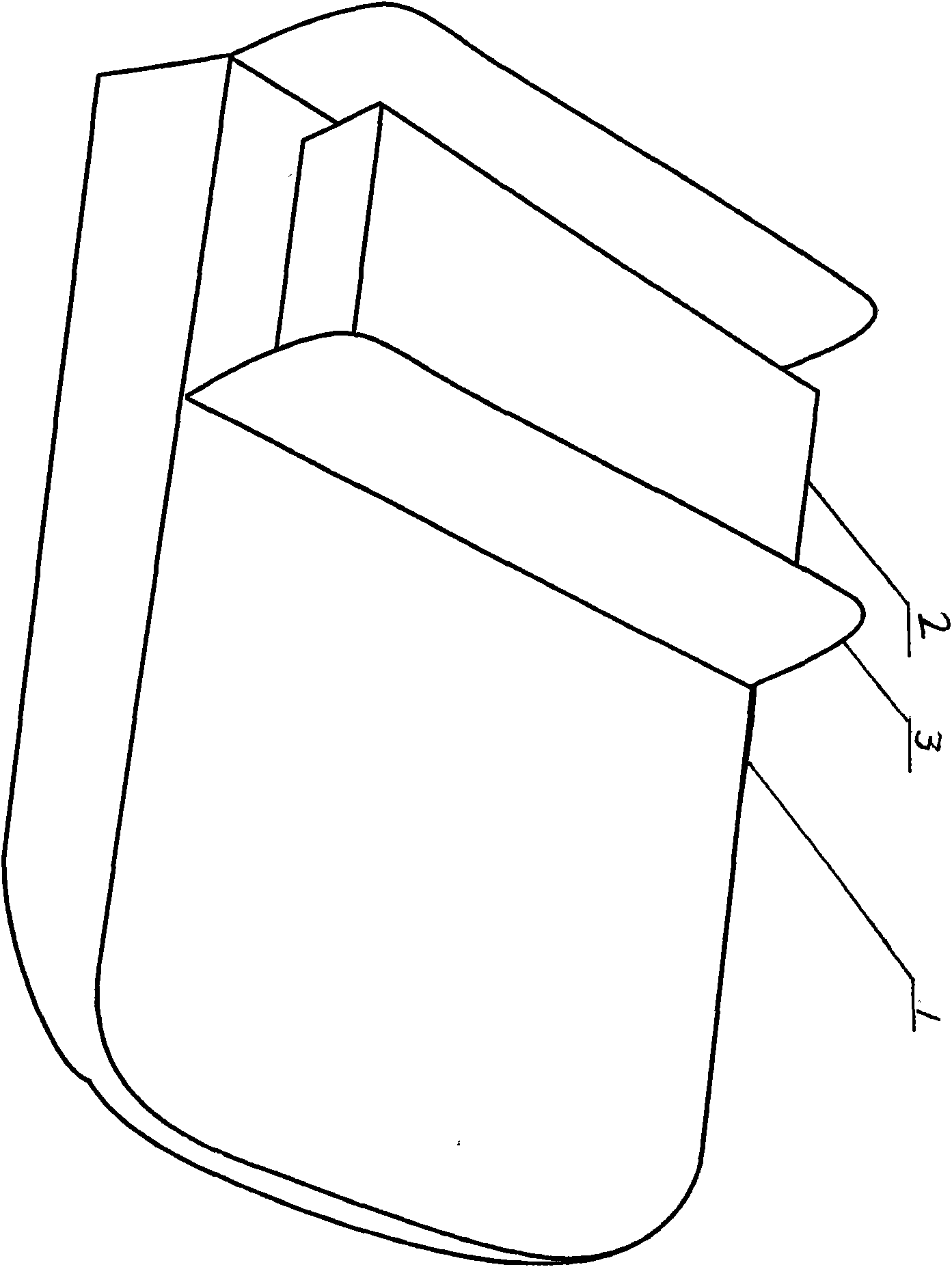

[0008] According to the accompanying drawings (such as figure 1 , figure 2 , image 3 Figure 4 Shown) do further explanation to the present invention: a kind of manufacturing method of rice transplanting seat, design has three embodiments, the first kind of embodiment: at first: hard plastic is heated and blow molded rice transplanting seat shell, then: fill benzene inside shell plate to form an integral rice transplanting seat: the second embodiment: cast hard plastic into the shell of the rice transplanting seat, and then: fill the inside of the shell with benzene plates to form an integral rice transplanting seat: the shells of the two options can be The whole is designed as an empty shell, and then filled with benzene boards in the empty shell; it is also possible to design the interior of the seedling transplanting seat shell as a partition space, and each space will form a fulcrum; the third embodiment is: design the benzene board into the shape of the rice transplan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com