Fixture for grinding processing ultra-thin wall parts

A technology for parts and ultra-thin walls, which is applied in the field of processing fixtures for ultra-thin-wall parts, can solve the problems of difficult work, low efficiency and high rejection rate, and achieve the effect of improving product qualification rate, production efficiency and output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

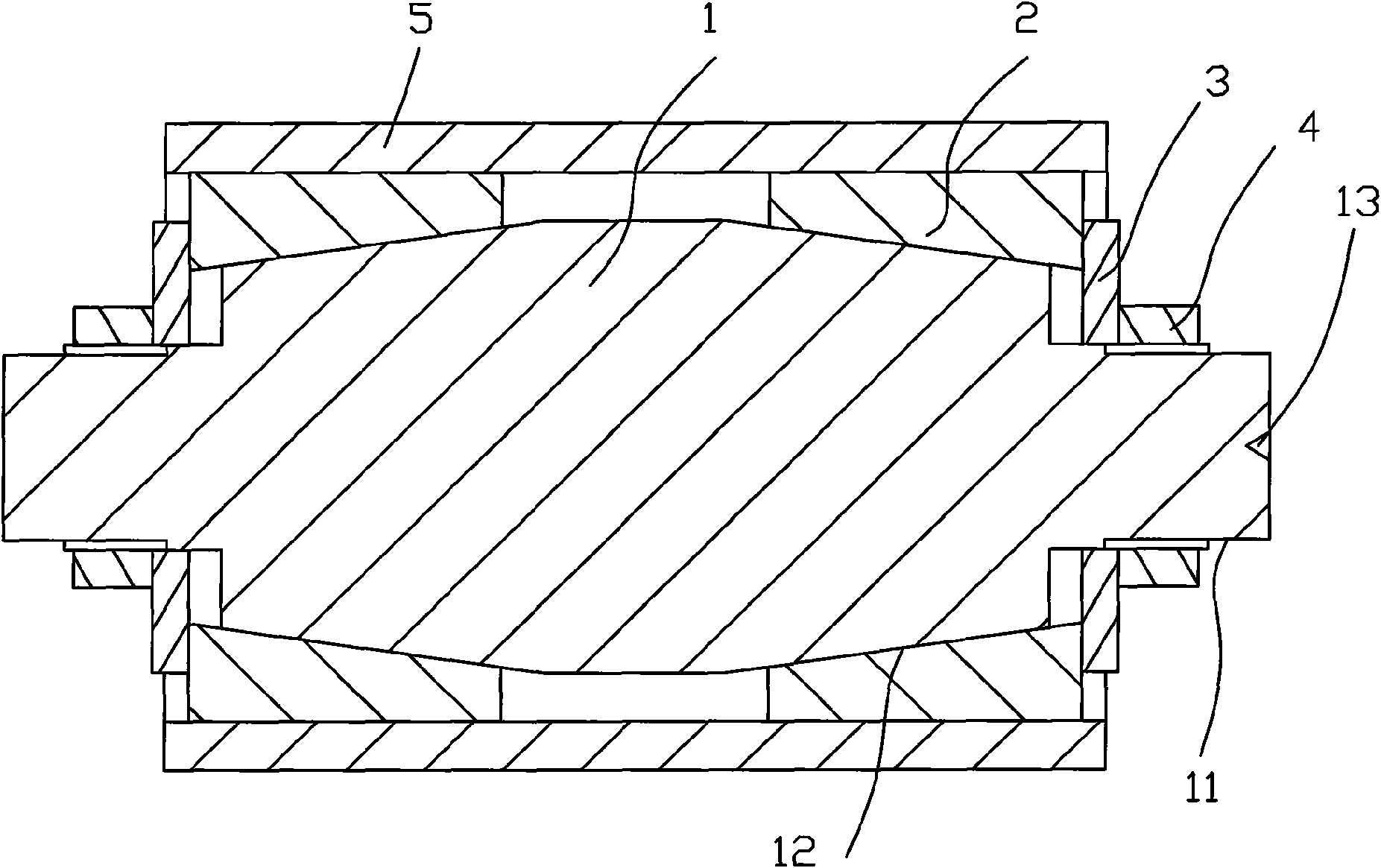

[0012] Such as figure 1 As shown, it is an embodiment of an ultra-thin-wall parts turning and grinding fixture of the present invention, which includes a mandrel 1, and a step 11 is provided at both ends of the mandrel, and the diameter gradually changes from the end surface of the step to the middle of the mandrel. A large conical inclined surface 12, a sleeve 2 is sleeved on the conical inclined surface, and the inner wall of the sleeve is conically matched with the conical inclined surface 12 of the mandrel. 3 compress, and the pressing plate is regulated and compressed by the adjusting nut 4. A center hole 13 is provided at the center of the right end of the mandrel. The angle of the tapered slope 12 is greater than the self-locking angle between the sleeve 2 and the mandrel 1 .

[0013] During the turning and grinding process, the mandrel 1 is put on the sleeve 2, and several conjoined ultra-thin-walled parts 5 are placed on the mandrel 1, and then the sleeve is adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com