Method for controlling bed temperature of fixed bed hydrogenation reactor

A hydrogenation reactor and a hydrogenation reaction technology are applied in the fields of controlling the temperature of the reactor and controlling the bed temperature of the fixed bed hydrogenation reactor, and can solve the problem that the radial temperature difference of the hydrogenation reactor bed is large, and the conversion rate and product are affected. Quality, can not guarantee all the vaporization of cold oil, etc., to achieve the effect of improving the distribution effect, reducing requirements, and avoiding accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

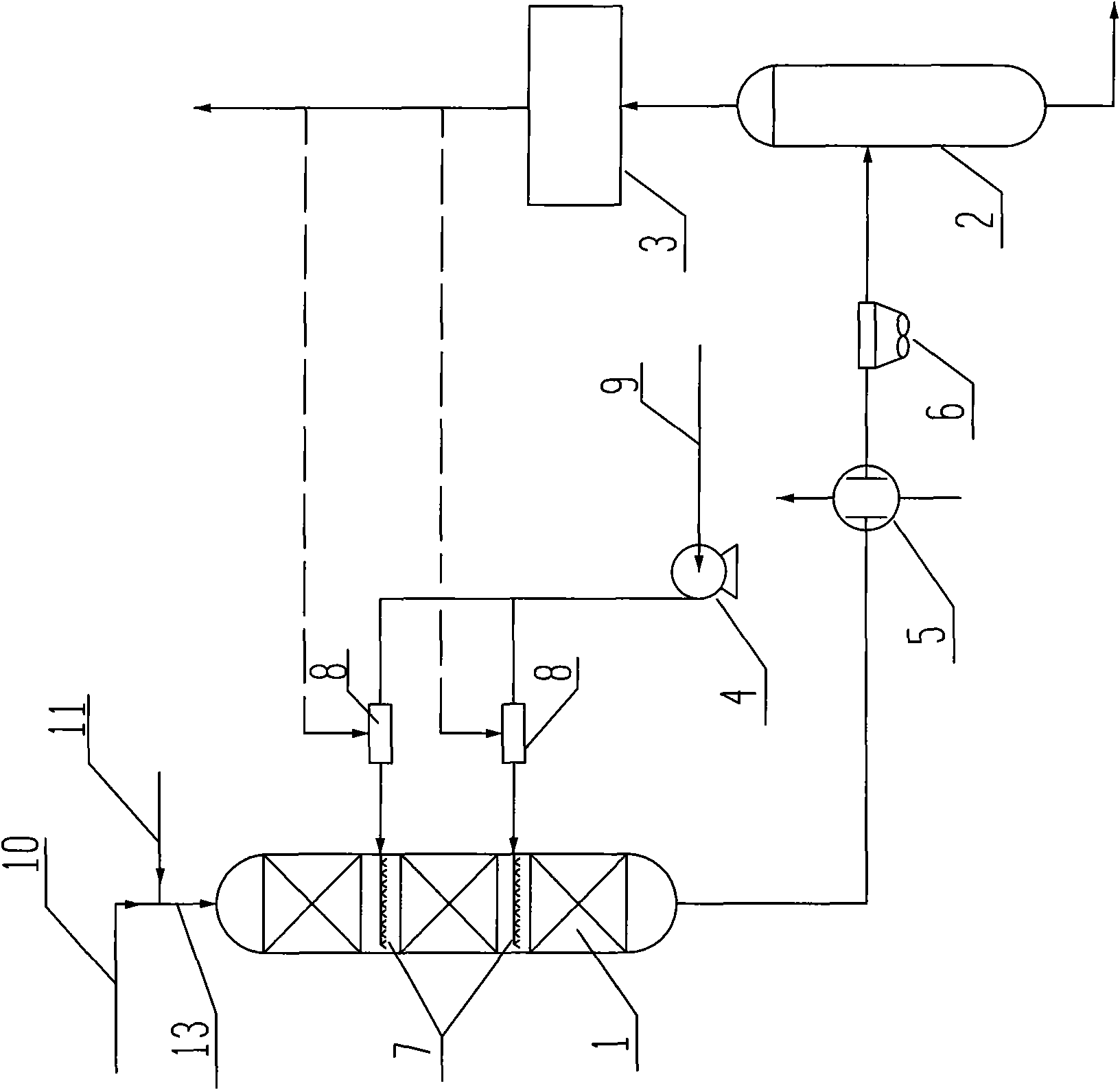

Image

Examples

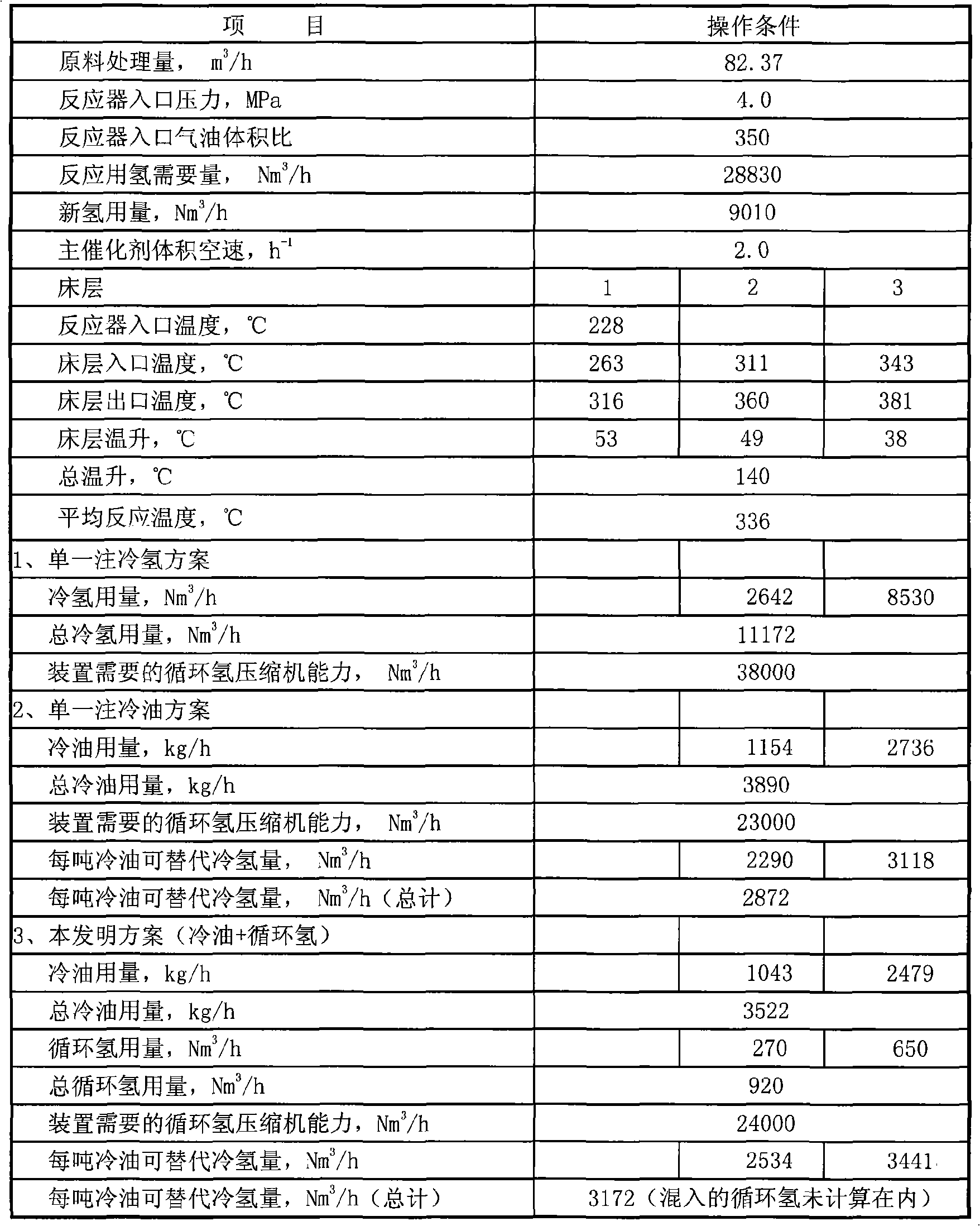

Embodiment 1

[0027] Taking a 500,000-ton / year coker gasoline hydrogenation unit as an example, the effect comparison between injection of cold hydrogen and cold oil between reactor beds and the scheme of the present invention is shown in Table 1 (the cold oil is the product refined gasoline).

[0028] Table 1 Comparison of Hydrogenation of Coked Gasoline

[0029]

Embodiment 2

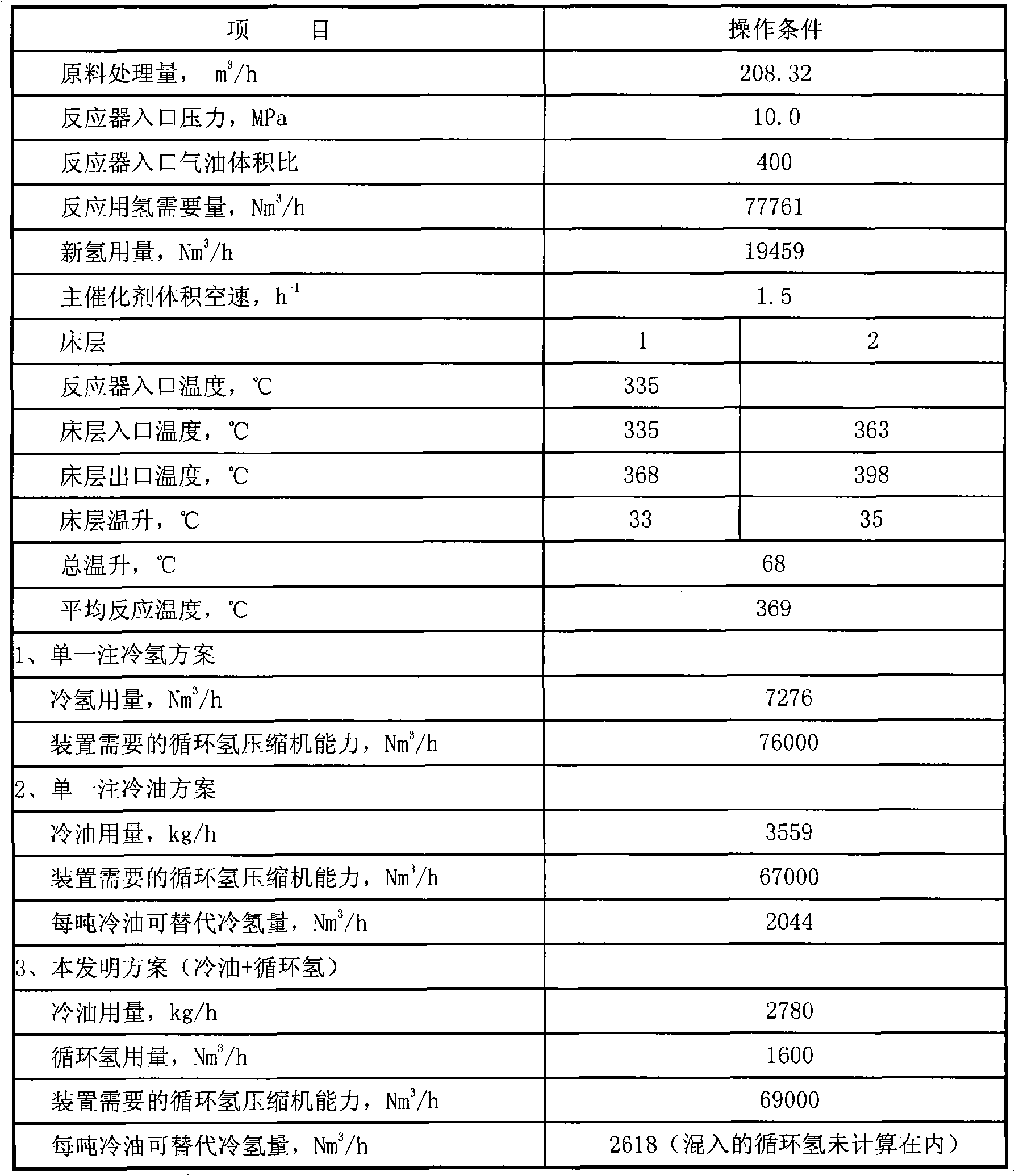

[0031] Taking the 1.4 million tons / year catalytic coking gasoline and diesel hydrogenation unit as an example, the effect comparison between injection of cold hydrogen and cold oil between reactor beds and the scheme of the present invention is shown in Table 2 (the cold oil is the product naphtha).

[0032] Table 2 Comparative results of catalytic coking gasoline and diesel hydrogenation

[0033]

Embodiment 3

[0035] Taking the 1.3 million tons / year high-pressure hydrocracking unit as an example, the effect comparison between injection of cold hydrogen and cold oil between the reactor beds and the scheme of the present invention is shown in Table 3 (the cold oil is the product naphtha):

[0036] Table 3 Comparison results of high pressure hydrocracking hydrogenation

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com