Two-way cutter point support centring and levelling test device

A test device and knife-edge technology, which is applied in the direction of measuring devices, testing of mechanical components, and testing of machine/structural components, etc., can solve the problem of separation between the test piece and the knife-edge support, small contact area at the knife-edge, and high height of the knife-edge support, etc. problems, to achieve the effect of improving test accuracy and test speed, improving centering and leveling efficiency, and simple processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

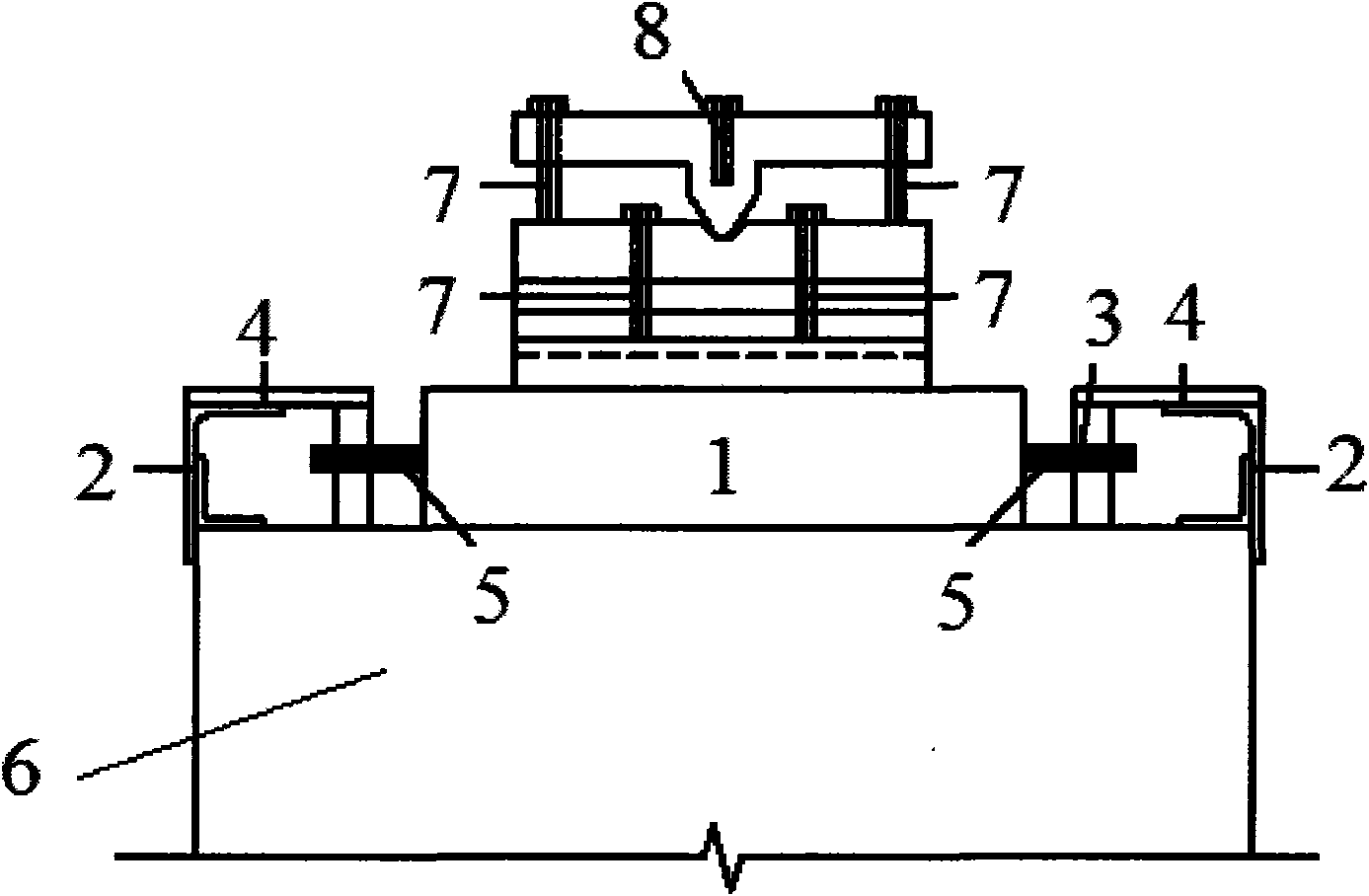

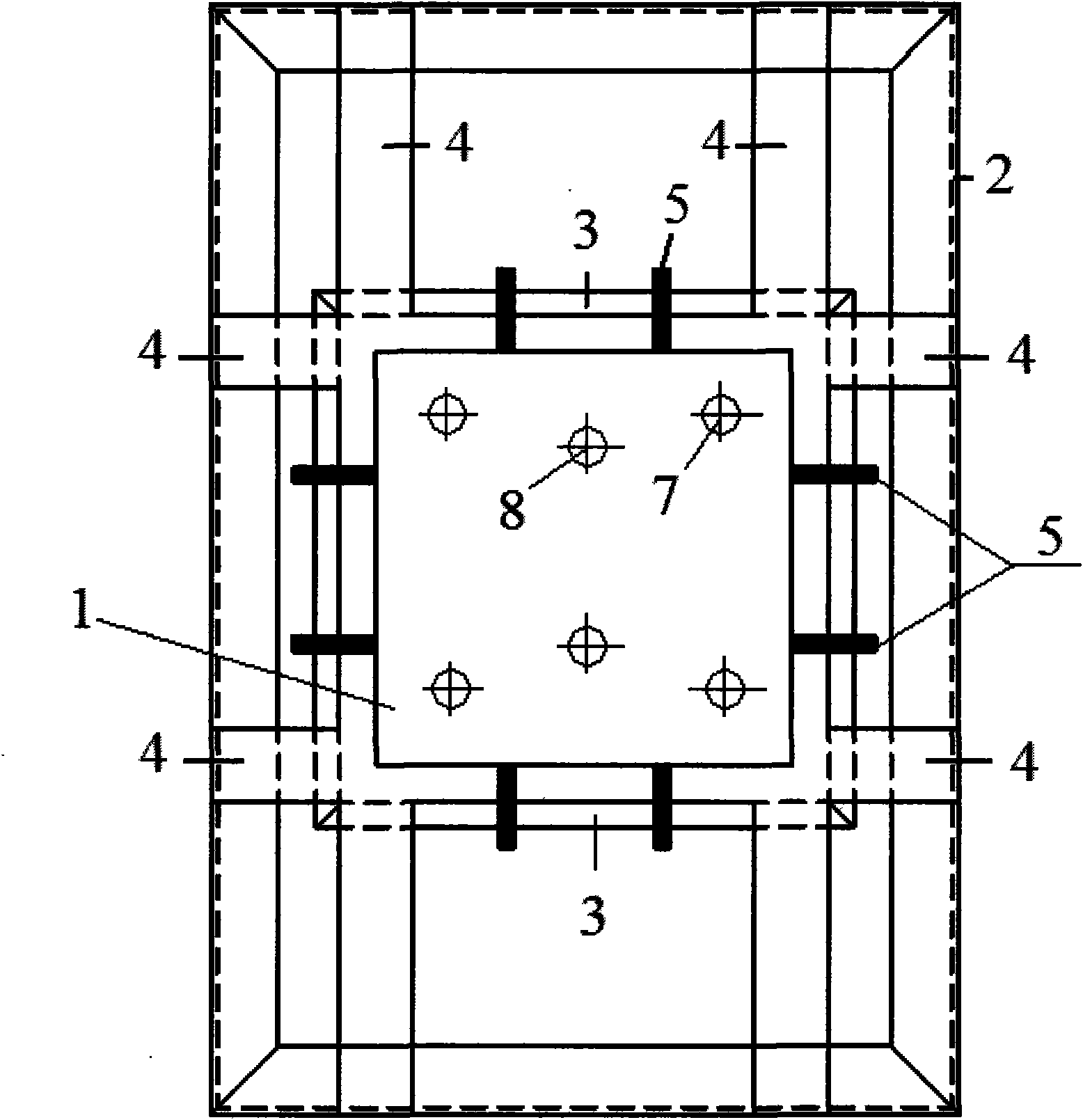

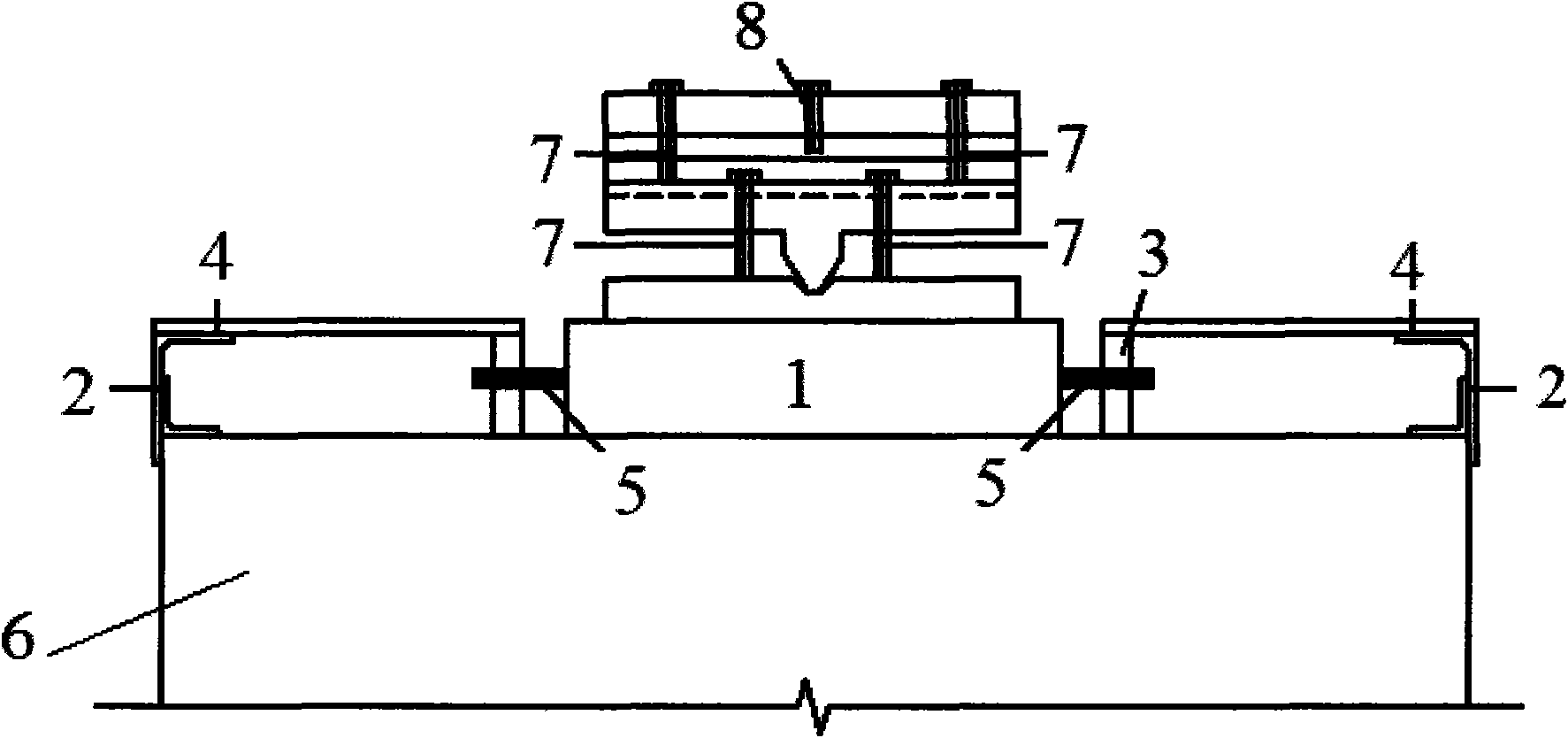

[0017] see Figure 1 ~ Figure 3 , the bidirectional knife-edge support centering and leveling test device of the present invention comprises the knife-edge support 1 arranged on the test bench 6, the knife-edge support is composed of an upper knife-edge, a middle knife-edge, a lower knife-edge and a base plate, and the knife-edge support The periphery of 1 is provided with a leveling frame 3 and an outer frame 2 in sequence, one side of the leveling frame 3 is connected to the bottom plate of the knife-edge support 1 through a centering screw 5, and the other side of the leveling frame 3 is connected through a connecting plate 4 It is connected with the outer frame 2, and the outer frame 2 is integrated with the test bench 6; an adjustable screw rod 7 is provided on the upper blade edge and the middle blade edge, wherein, the adjustable screw rod 7 of the upper blade edge is in contact with the middle blade edge, and the middle blade edge The adjustable screw rod 7 is in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com