Electrification oil sample acquisition device for oil-immersed sleeve pipe of transformer

A transformer bushing and oil-immersed technology, which is applied in the direction of sampling device, transformer/inductor cooling, etc., can solve the problems of unreliable sealing, long maintenance cycle, water ingress and moisture, etc., so as to delay the aging degree, improve the insulation level, The effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

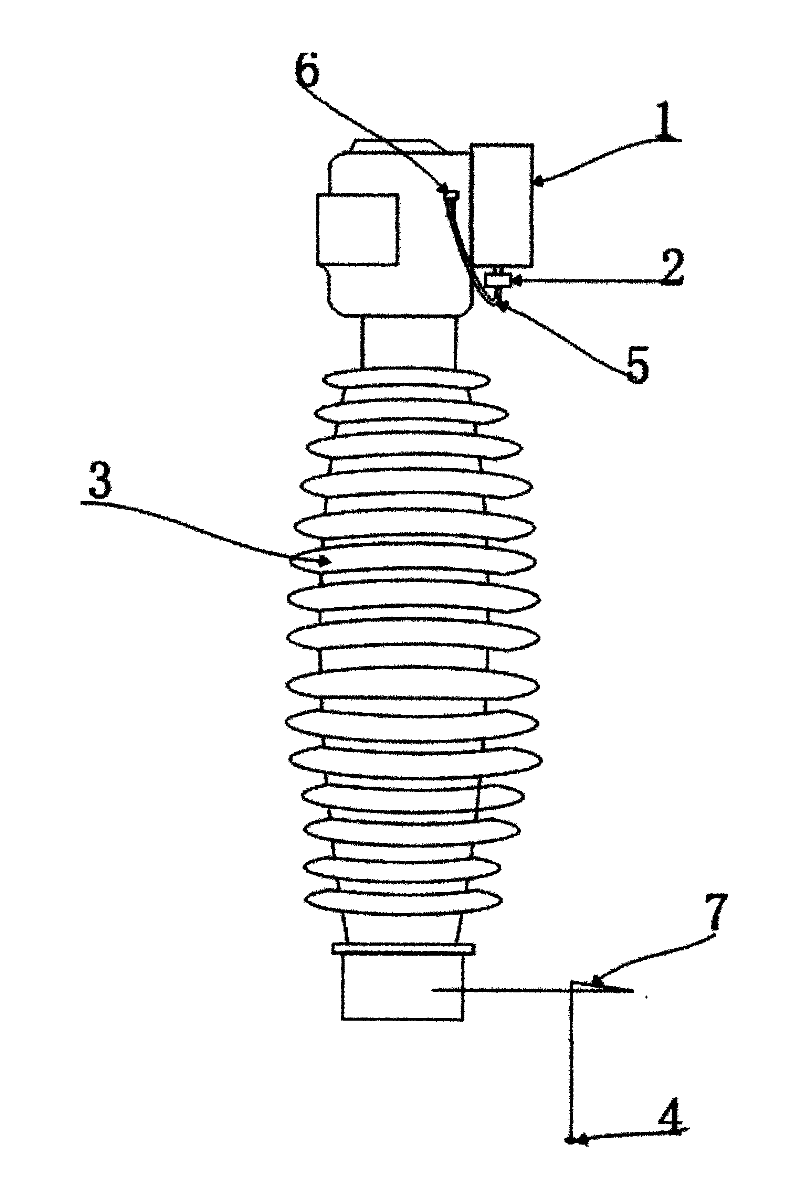

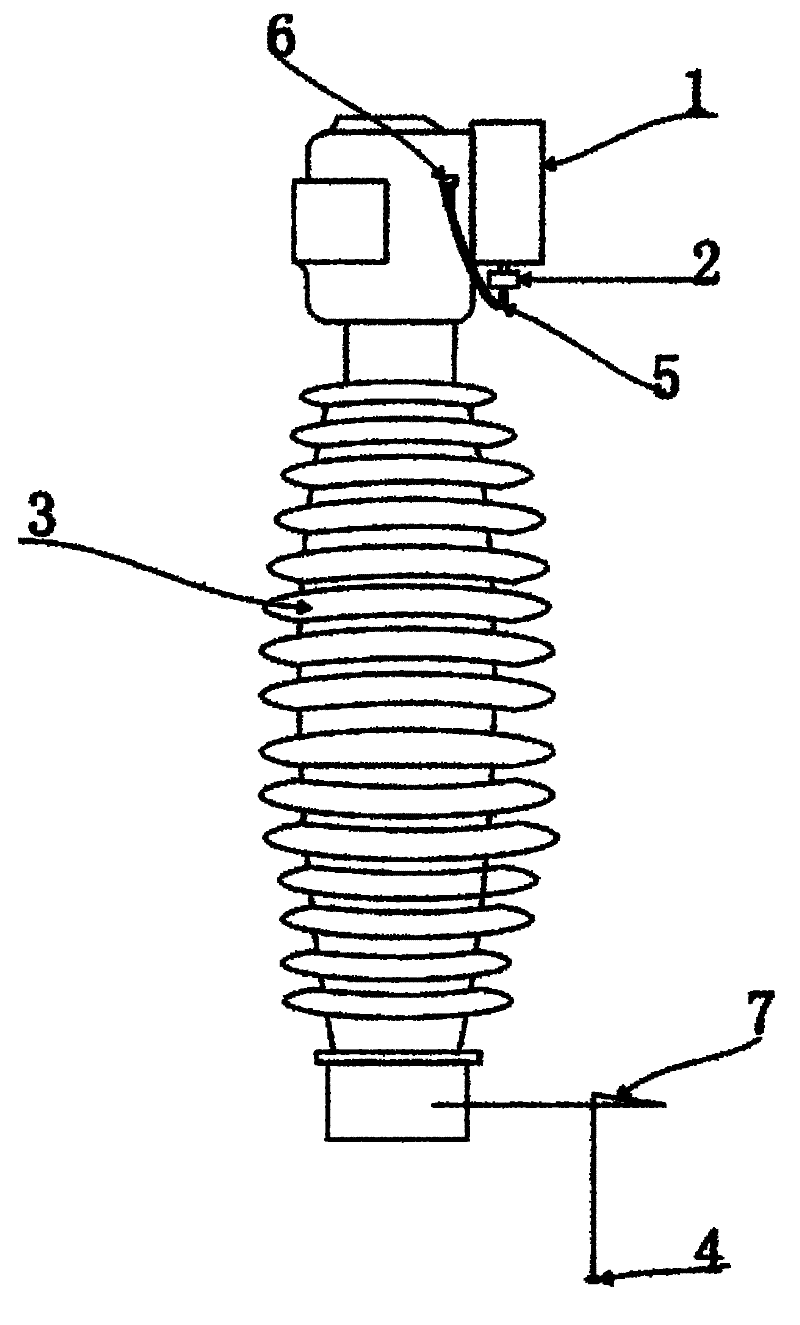

[0022] Below we will further illustrate the present invention in conjunction with the accompanying drawings. A transformer oil-immersed bushing live oil sampling device includes a corrugated metal expander oil conservator 1, a four-way valve 2, a transformer bushing 3 and a needle. Sampling valve 4, corrugated metal expander oil conservator 1 hangs forward and is installed on the fastening bolt on the top of the general cap of transformer bushing 3, the lower end of corrugated metal expander oil conservator 1 is provided with four-way valve 2, The vertical lower interface of the four-way valve 2 is connected to the connecting pipe 5 through a joint. The left interface of the four-way valve 2 is an oil filling interface and is equipped with an oil replenishment check valve. The right interface of the four-way valve 2 is a vacuum interface and is equipped with a vacuum check valve. valve. The connecting pipe 5 is connected to the exhaust hole of the transformer bushing 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com