Reinforcing agent for modifying acidic aggregate asphalt mixture and application

A technology of asphalt mixture and acid aggregate, which is applied in the field of road construction materials, to achieve the effect of reducing the degree of aging, ideal social benefits, and reducing harm to people and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A reinforcing agent for the modification of the above-mentioned acid aggregate asphalt mixture, including modifier A and modifier B used in conjunction; the quality of modifier A is 0.2% of the quality of the above-mentioned base asphalt, and the modifier B The mass of the acidic aggregate asphalt mixture is 1% of the total mass;

[0022] Modifier A is silane coupling agent KH550, and modifier B is 300 mesh natural asphalt solid powder.

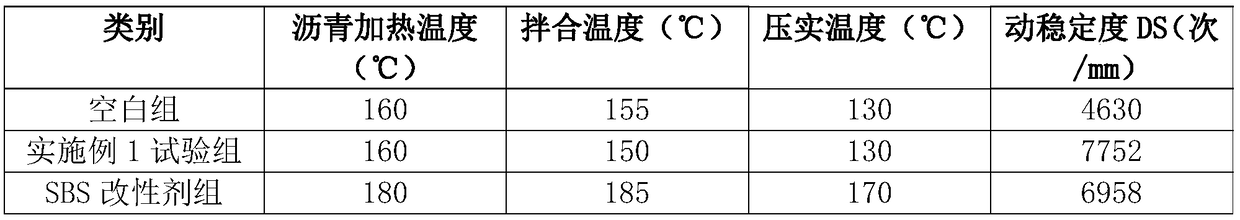

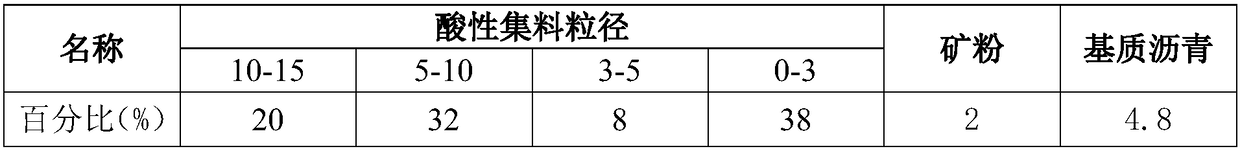

[0023] The specific ratio of acid aggregate asphalt mixture suitable for the lower layer of the road is shown in Table 1:

[0024] Table 1

[0025]

[0026] The amount of base asphalt in Table 1 above adopts the internal mixing method.

[0027] On the basis of the above-mentioned acid aggregate asphalt mixture used for the lower layer of the road, the reinforcing agent of this embodiment was added for modification, and the modified asphalt mixture for acid aggregate was obtained.

[0028] The application of the reinforcing agent ...

Embodiment 2

[0036] A reinforcing agent for the modification of the above-mentioned acidic aggregate asphalt mixture, including modifier A and modifier B used in conjunction; the quality of modifier A is 2% of the quality of the above-mentioned base asphalt, and the modifier B The quality of the acidic aggregate asphalt mixture is 0.4% of the total mass;

[0037] Modifier A is silane coupling agent KH570, and modifier B is 600 mesh natural asphalt solid powder.

[0038] The acidic aggregate asphalt mixture suitable for the middle surface of the road, the specific ratio is shown in Table 3 below:

[0039] table 3

[0040]

[0041] The amount of base asphalt in Table 3 above adopts the internal mixing method.

[0042] On the basis of the above-mentioned acidic aggregate asphalt mixture used for the road middle surface layer, the reinforcing agent of this embodiment is added for modification, and the modified asphalt mixture for acidic aggregate is obtained.

[0043] The application of ...

Embodiment 3

[0051] A reinforcing agent for the modification of the above-mentioned acidic aggregate asphalt mixture, including modifier A and modifier B used in conjunction; the quality of modifier A is 1% of the quality of the above-mentioned base asphalt, and the modifier B The mass of the acidic aggregate asphalt mixture is 0.7% of the total mass;

[0052] Modifier A is silane coupling agent KH550, and modifier B is 400 mesh natural asphalt solid powder.

[0053] The acid aggregate asphalt mixture suitable for the upper layer of the road, the specific ratio is shown in Table 5 below:

[0054] table 5

[0055]

[0056] The dosage of asphalt and fiber in the above table 5 are all adopted internal blending method.

[0057] On the basis of the above-mentioned acidic aggregate asphalt mixture used for the upper layer of the road, the reinforcement agent of this embodiment was added for modification, and the modified asphalt mixture for acidic aggregate was obtained.

[0058] The applica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com