Repairing agent for cracks on bituminous pavement and preparation method thereof

A technology for asphalt pavement and pavement cracks, applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve the problems of long closing time of traffic, slow drying, and inability to quickly resume traffic, so as to achieve easy moisture volatilization and improve Stability, the effect of shortening the time to open traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

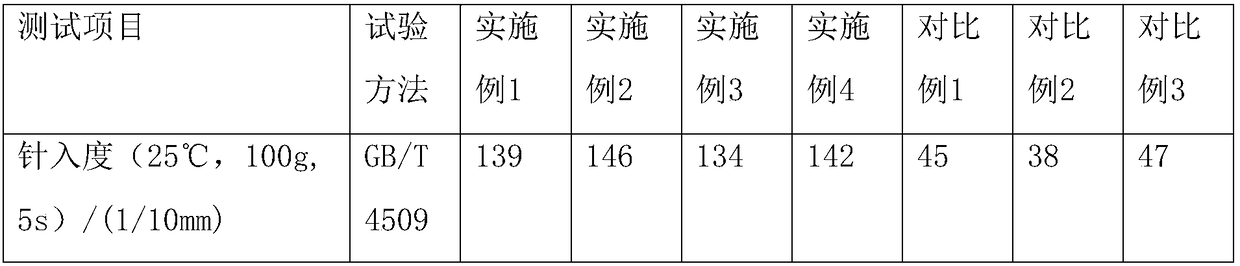

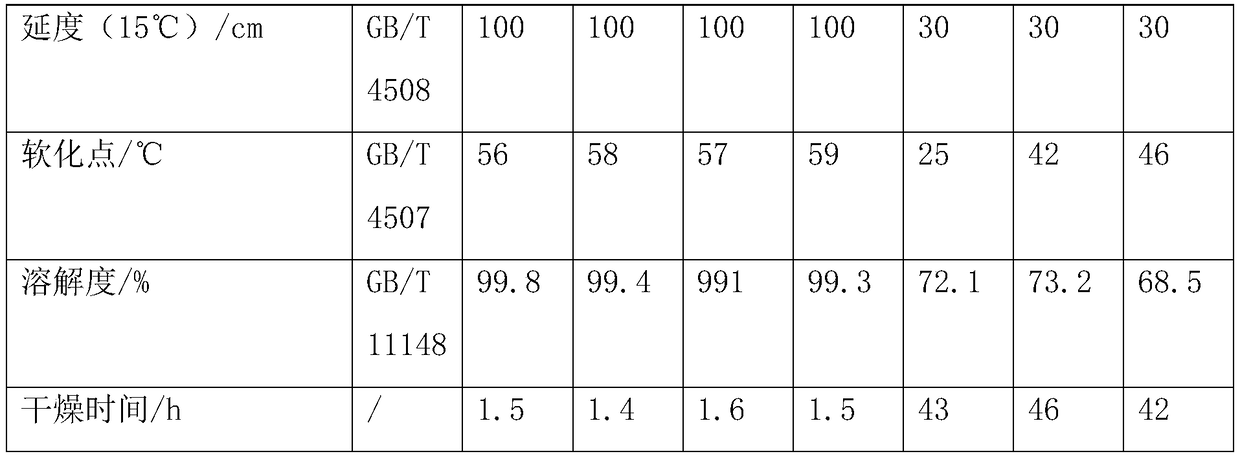

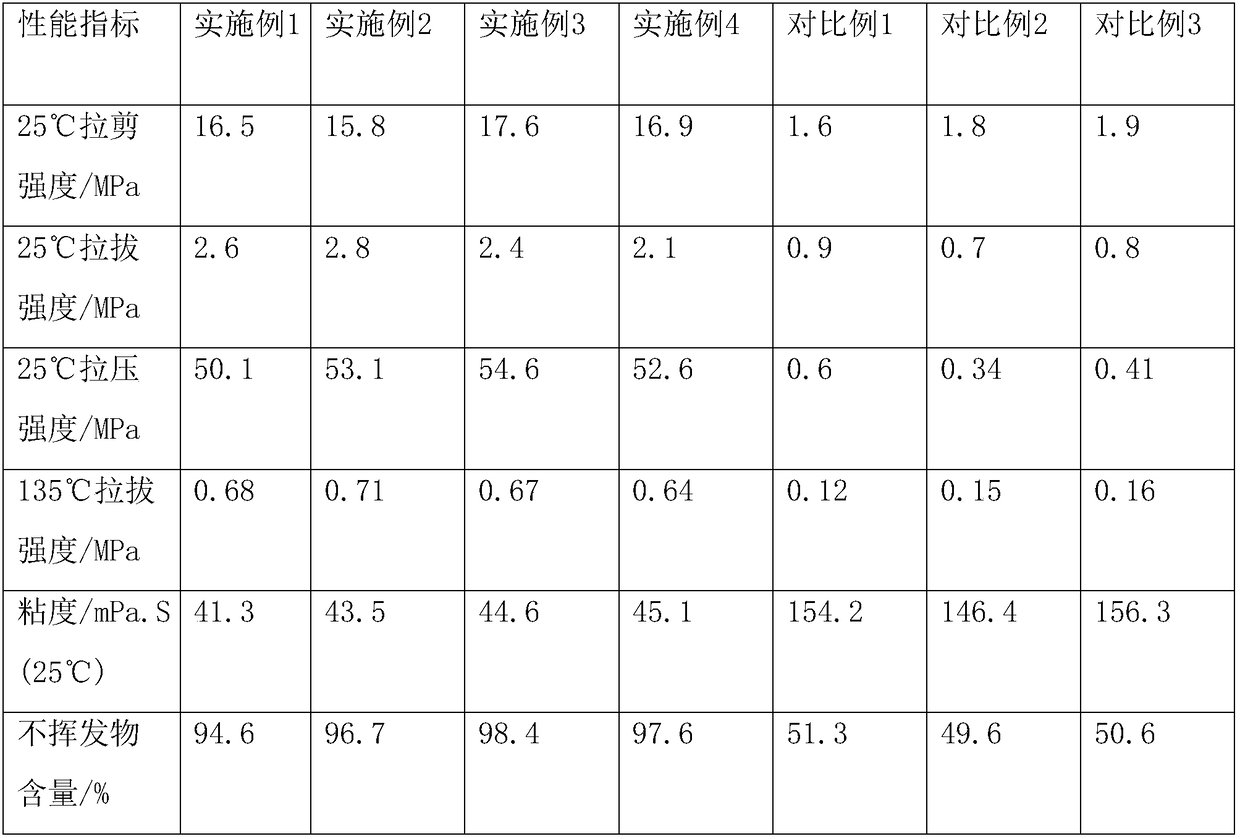

Examples

Embodiment 1

[0035] Embodiment 1: A crack repairing agent for asphalt pavement, comprising the following components by weight: 65 parts of epoxy resin emulsion compounded SBS asphalt liquid, 6 parts of polypropylene adipate polyester, 15 parts of 50-mesh rubber powder, C5 3 parts of / C9 copolymerized petroleum resin, 5 parts of lignin fiber with an average length of 3mm;

[0036] Wherein the epoxy resin emulsion compounded SBS asphalt liquid is composed of the following parts by weight: 15 parts of epoxy resin emulsion, 30 parts of cold-mix SBS asphalt liquid, and 1.5 parts of fixative;

[0037] The preparation method of epoxy resin emulsion compounded with SBS asphalt liquid is as follows: add 30 parts of cold-mixed SBS asphalt liquid to 15 parts of epoxy resin emulsion, stir while adding, and then add 1.5 parts of curing agent to the mixed liquid while stirring , and stir evenly to prepare epoxy resin emulsion compound SBS asphalt liquid;

[0038] Among them, the epoxy resin emulsion is...

Embodiment 2

[0043] Embodiment 2: A crack repairing agent for asphalt pavement, comprising the following components by weight: 78 parts of epoxy resin emulsion compounded SBS asphalt liquid, 10 parts of polypropylene adipate polyester, 21 parts of 50-mesh rubber powder, C5 5 parts of / C9 copolymerized petroleum resin, 7 parts of lignin fiber with an average length of 3mm;

[0044] Wherein the epoxy resin emulsion compounded SBS asphalt liquid is composed of the following parts by weight: 20 parts of epoxy resin emulsion, 40 parts of cold-mixed SBS asphalt liquid, and 2 parts of fixative;

[0045] The preparation method of epoxy resin emulsion compounded with SBS asphalt liquid is as follows: add 40 parts of cold-mixed SBS asphalt liquid to 20 parts of epoxy resin emulsion, stir while adding, and then add 2 parts of curing agent to the mixed liquid while stirring , and stir evenly to prepare epoxy resin emulsion compound SBS asphalt liquid;

[0046] Among them, the epoxy resin emulsion is ...

Embodiment 3

[0051] Embodiment 3: A crack repairing agent for asphalt pavement, comprising the following components by weight: 80 parts of epoxy resin emulsion compounded SBS asphalt liquid, 13 parts of polypropylene adipate polyester, 27 parts of 50-mesh rubber powder, C5 7 parts of / C9 copolymerized petroleum resin, 9 parts of lignin fibers with an average length of 3mm;

[0052] Wherein the epoxy resin emulsion compounded SBS asphalt liquid is composed of the following parts by weight: 25 parts of epoxy resin emulsion, 50 parts of cold-mix SBS asphalt liquid, and 2.5 parts of fixative;

[0053] The preparation method of epoxy resin emulsion compounded with SBS asphalt liquid is as follows: add 50 parts of cold-mixed SBS asphalt liquid to 25 parts of epoxy resin emulsion, stir while adding, and then add 2.5 parts of curing agent to the mixed liquid while stirring , and stir evenly to prepare epoxy resin emulsion compound SBS asphalt liquid;

[0054] The epoxy resin emulsion is prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com