Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

A technology of a substrate processing device and a substrate processing method, which is applied to each unit, substrate processing device and substrate processing, substrate holding mechanism and substrate holding, various components or devices, and the field of substrate holding mechanism, which can solve the problem of unstable flow of pure water, etc. problems, to achieve reliable control, improve processing efficiency, and improve responsiveness and latency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] Hereinafter, embodiments of the substrate processing apparatus of the present invention will be described in detail with reference to the drawings. The same or equivalent structural elements are given the same reference numerals and their repeated description is omitted.

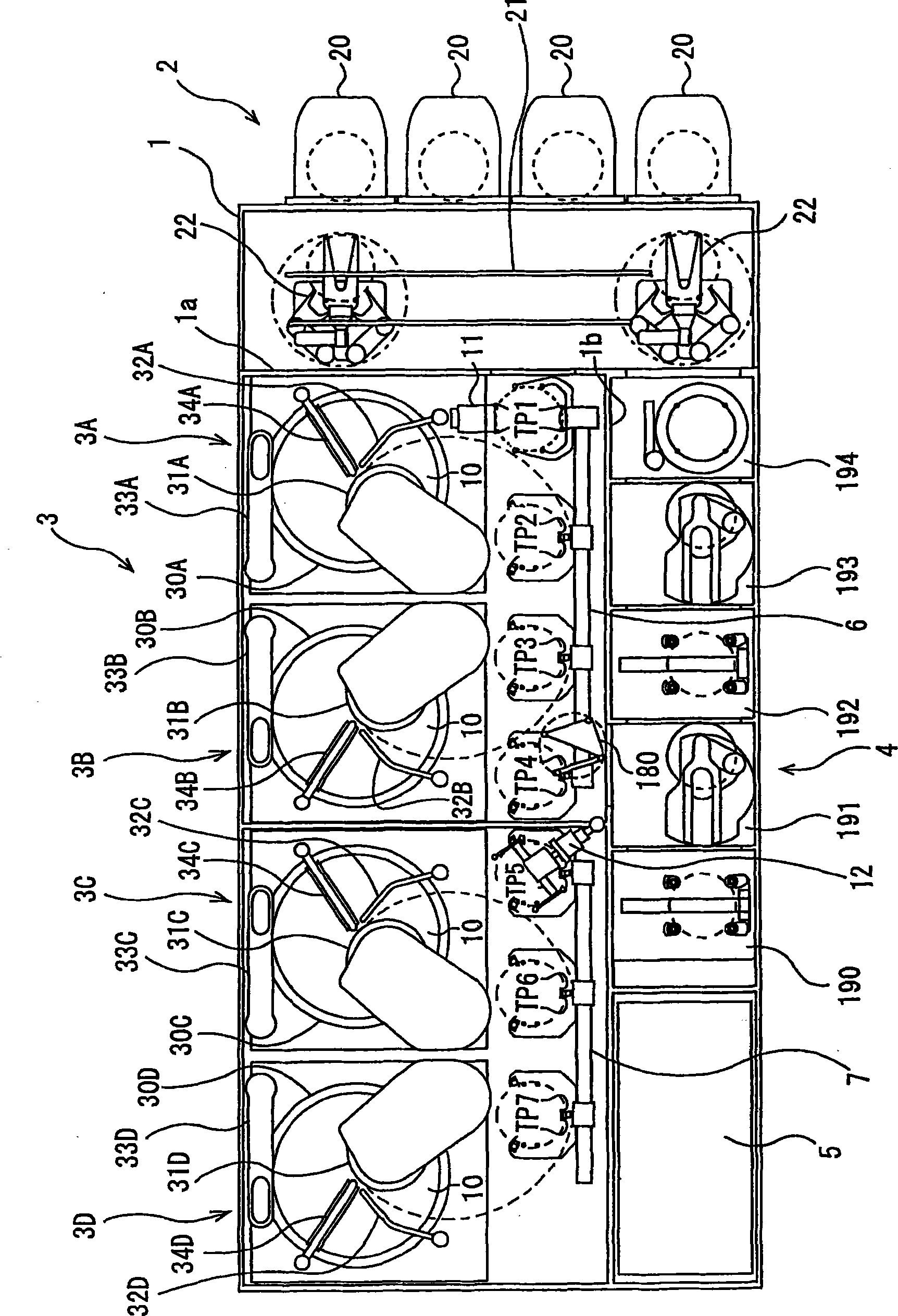

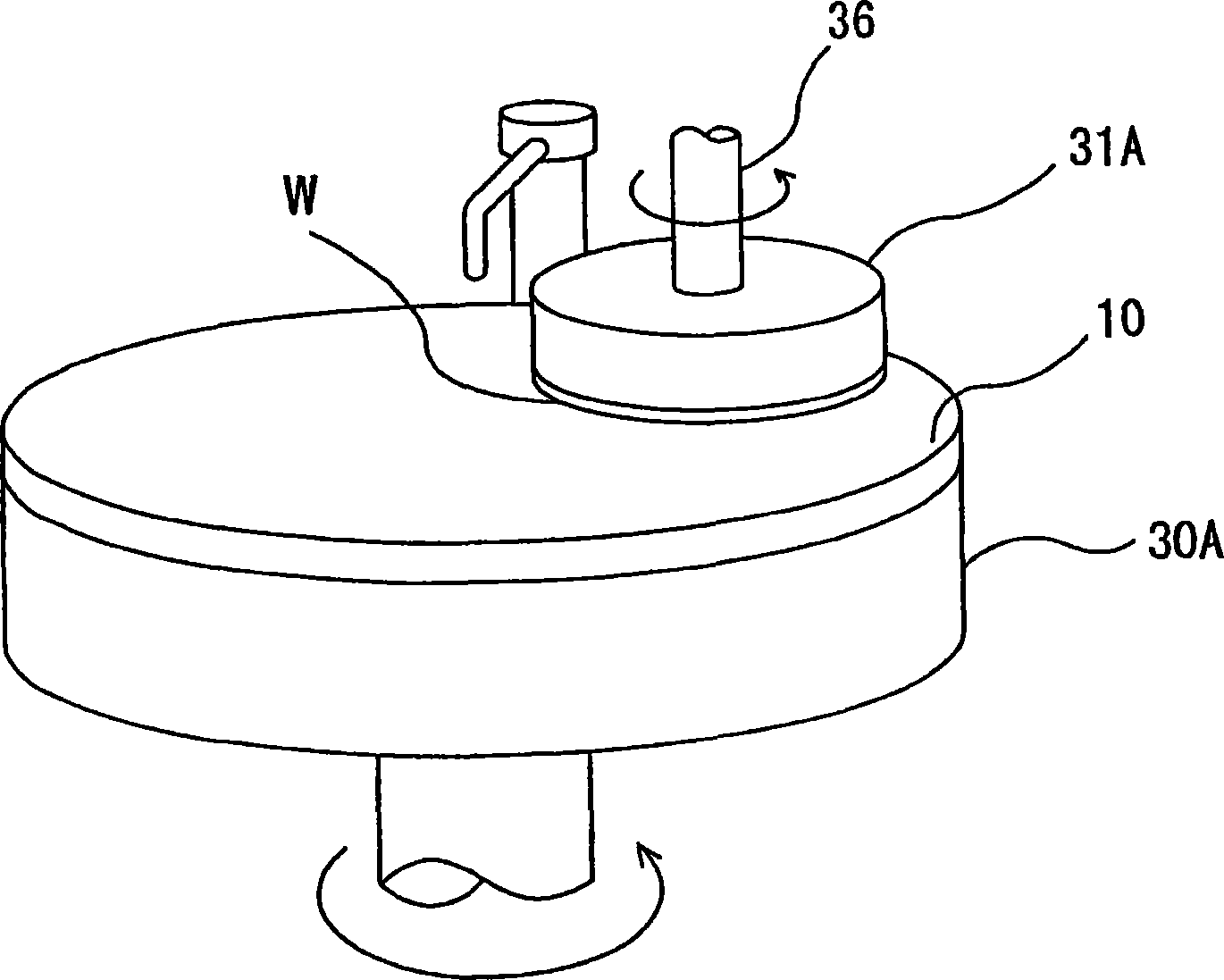

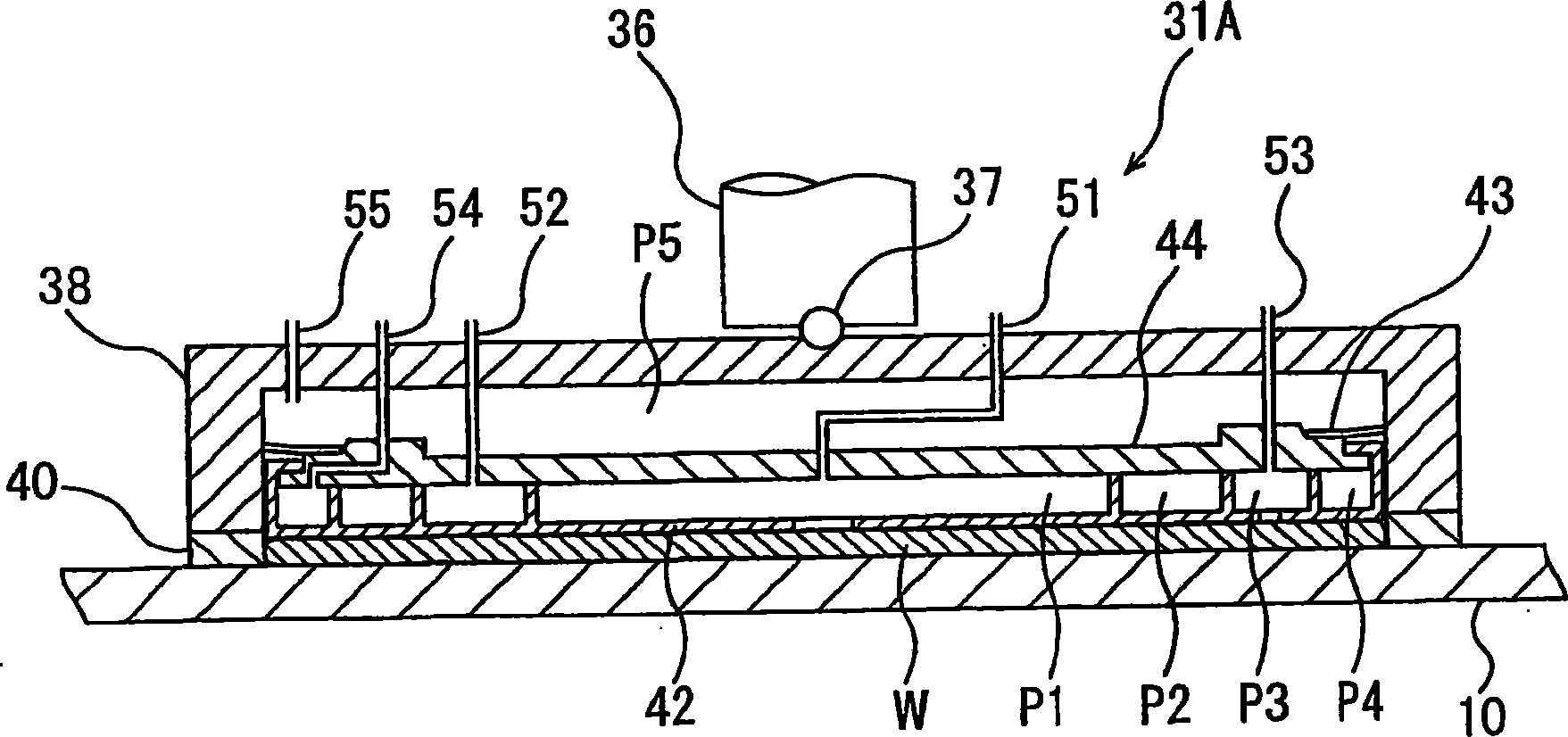

[0122] figure 1 It is a plan view showing the overall structure of a substrate processing apparatus according to an embodiment of the present invention. Such as figure 1 As shown, the substrate processing apparatus has a housing 1 having a substantially rectangular shape, and the interior of the housing 1 is divided into a load / unload part 2, a polishing part 3, and a cleaning part 4 by partition walls 1a and 1b. The loading / unloading section 2, the polishing section 3, and the cleaning section 4 described above are each independently combined and exhausted independently. In addition, the substrate processing apparatus has a control unit 5 that controls substrate processing operations.

[0123] The loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com