Sensorised multiplier

A gearbox and sensing technology, applied in the field of sensing gearboxes, can solve the problems of unmentioned loads and axial and radial forces, and achieve the effect of reducing maintenance costs and reducing the possibility of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

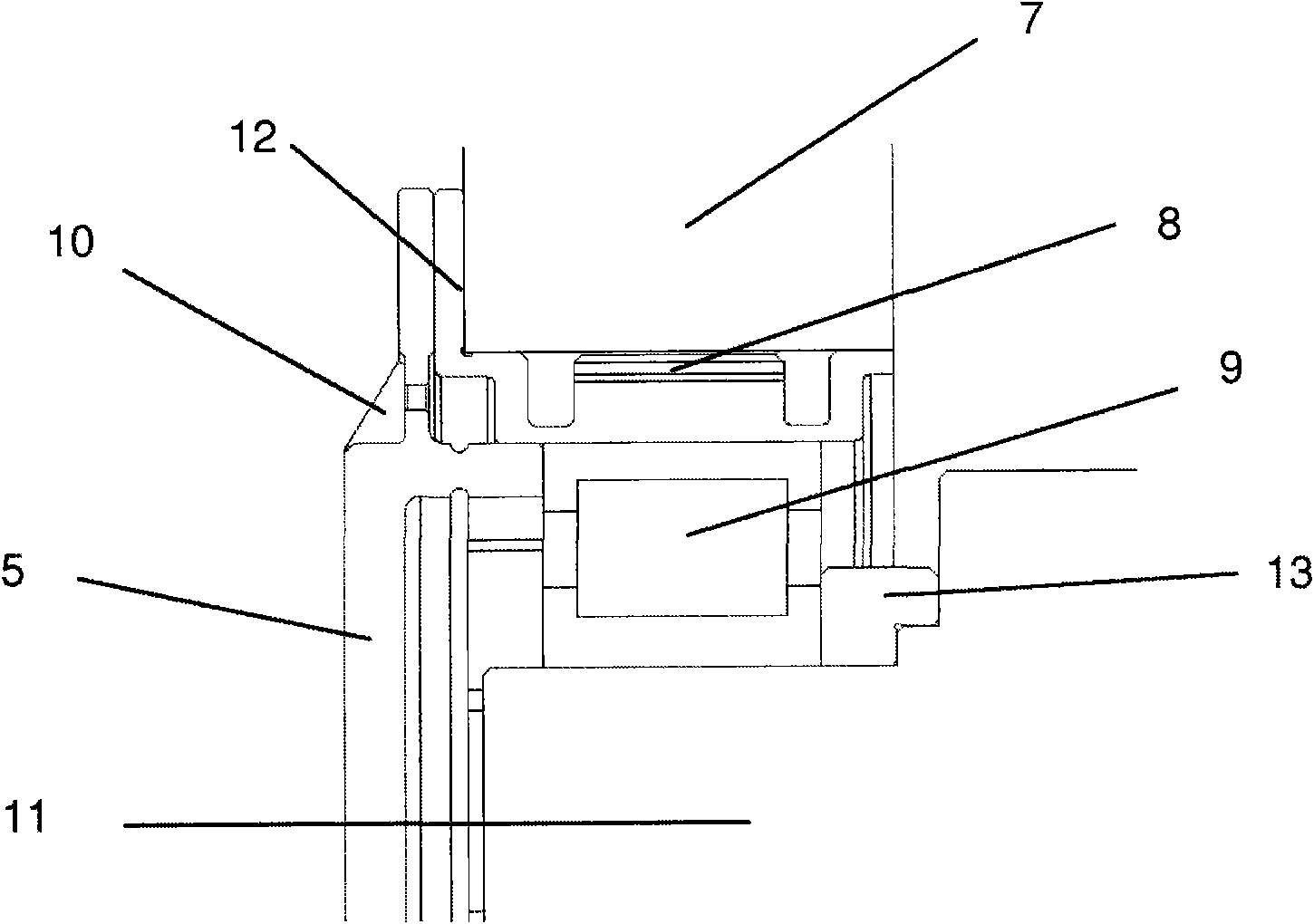

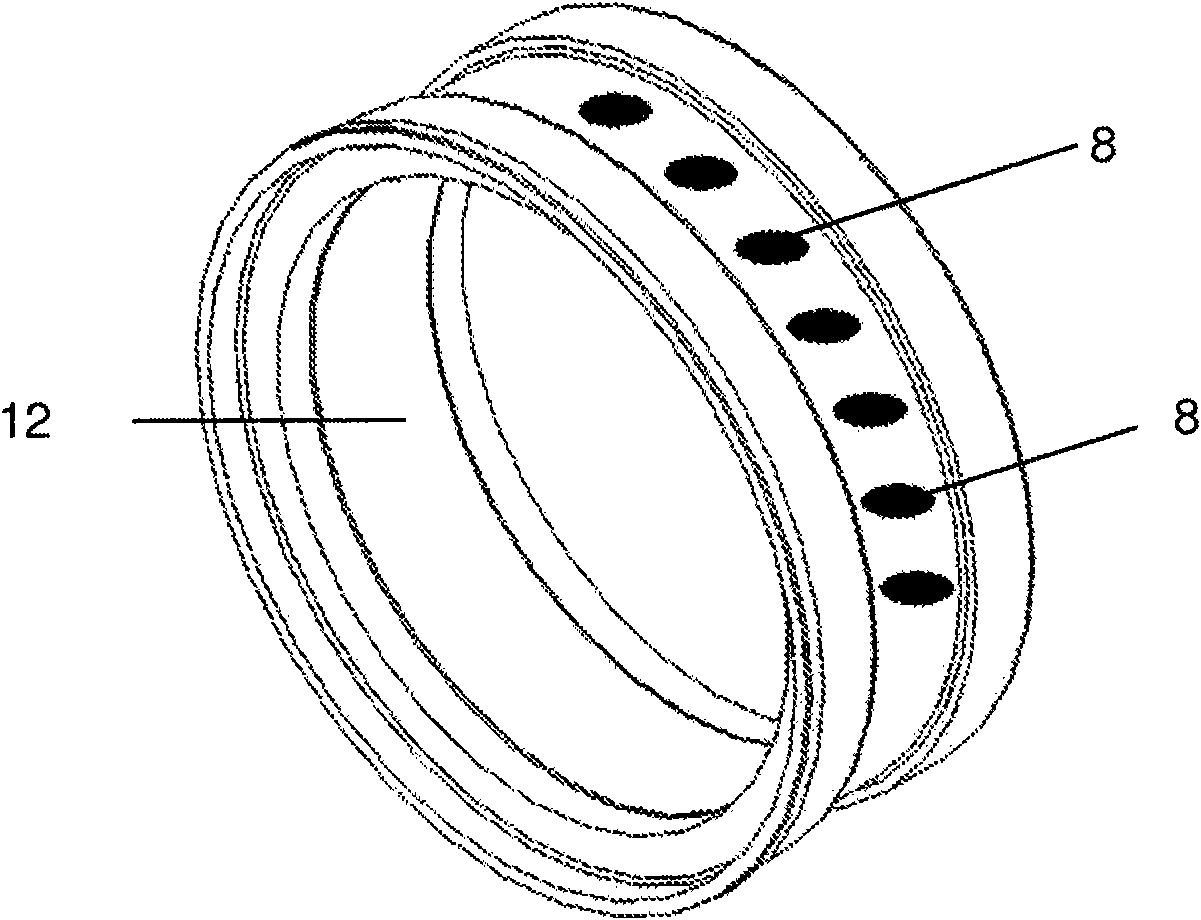

[0030] The shaft or axis whose reaction is to be measured is supported by two or more bushes or bearings which transmit axial and radial forces to the gearbox housing or case, we will measure the reaction of the rotating shaft force. The addition of sensing components enables the measurement of these radial and axial forces.

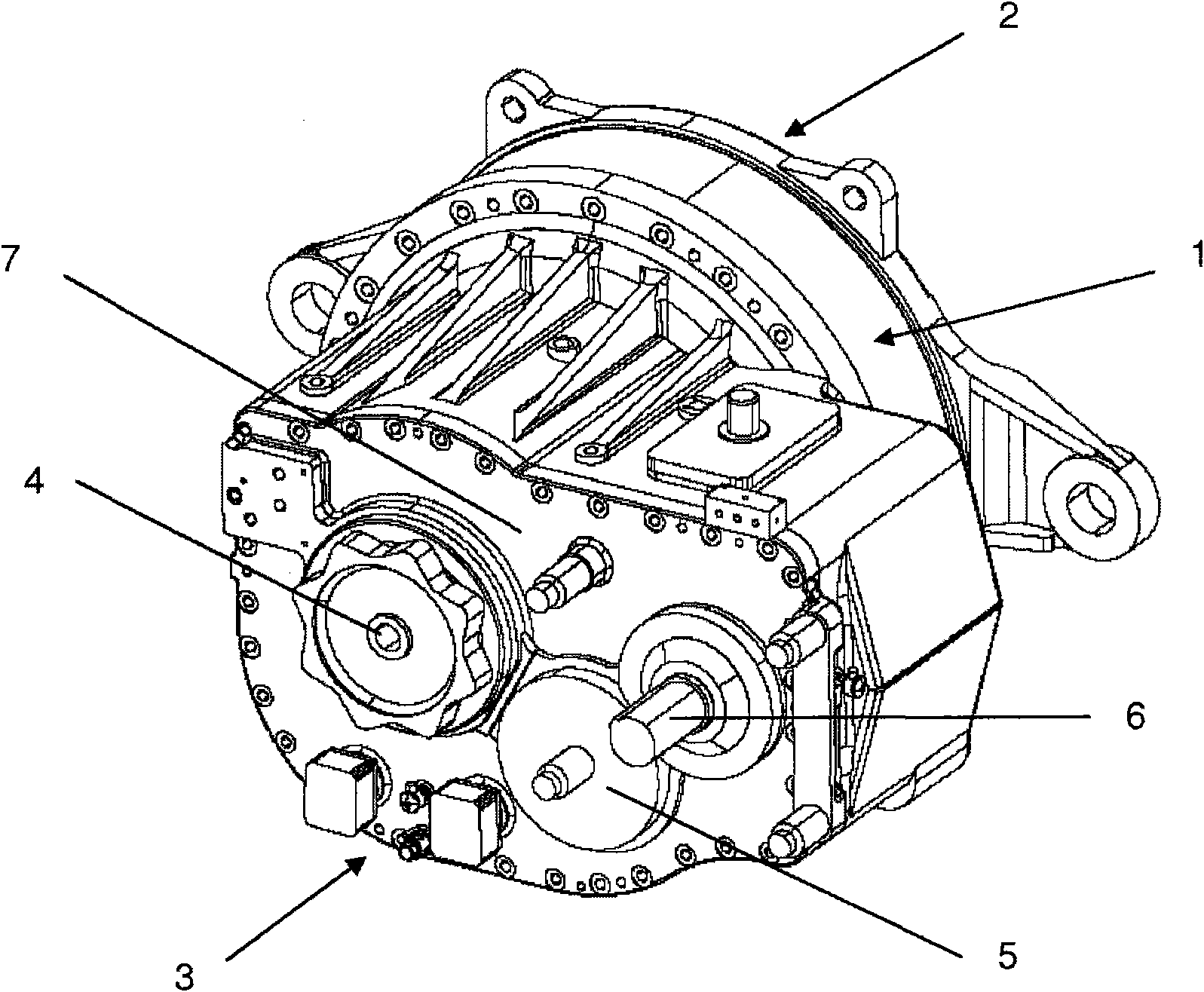

[0031] Such as figure 1 As shown, the gearbox comprises a main body (1) connected at one end to a rotor hub (2) and at the other end to a generator (3) (not shown). The side connected to the generator (3) is covered by a housing (7) with three main rear covers: main shaft cover (4), intermediate shaft cover (5) and quick shaft cover (6). The shaft and bearings of the gearbox are inside the housing, which covers and protects the aforementioned cover.

[0032] exist figure 2 , shows the cross-section of the intermediate shaft cover (5), in top plan view, the gearbox housing (7) can be seen inside it. Below the housing is a bushing (12) where the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com