Dishware washing machine

A tableware washing machine and tableware technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., which can solve the problem of the decrease of atomization amount, the influence of ultrasonic vibrator work, and the inability of ultrasonic vibrator Work and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

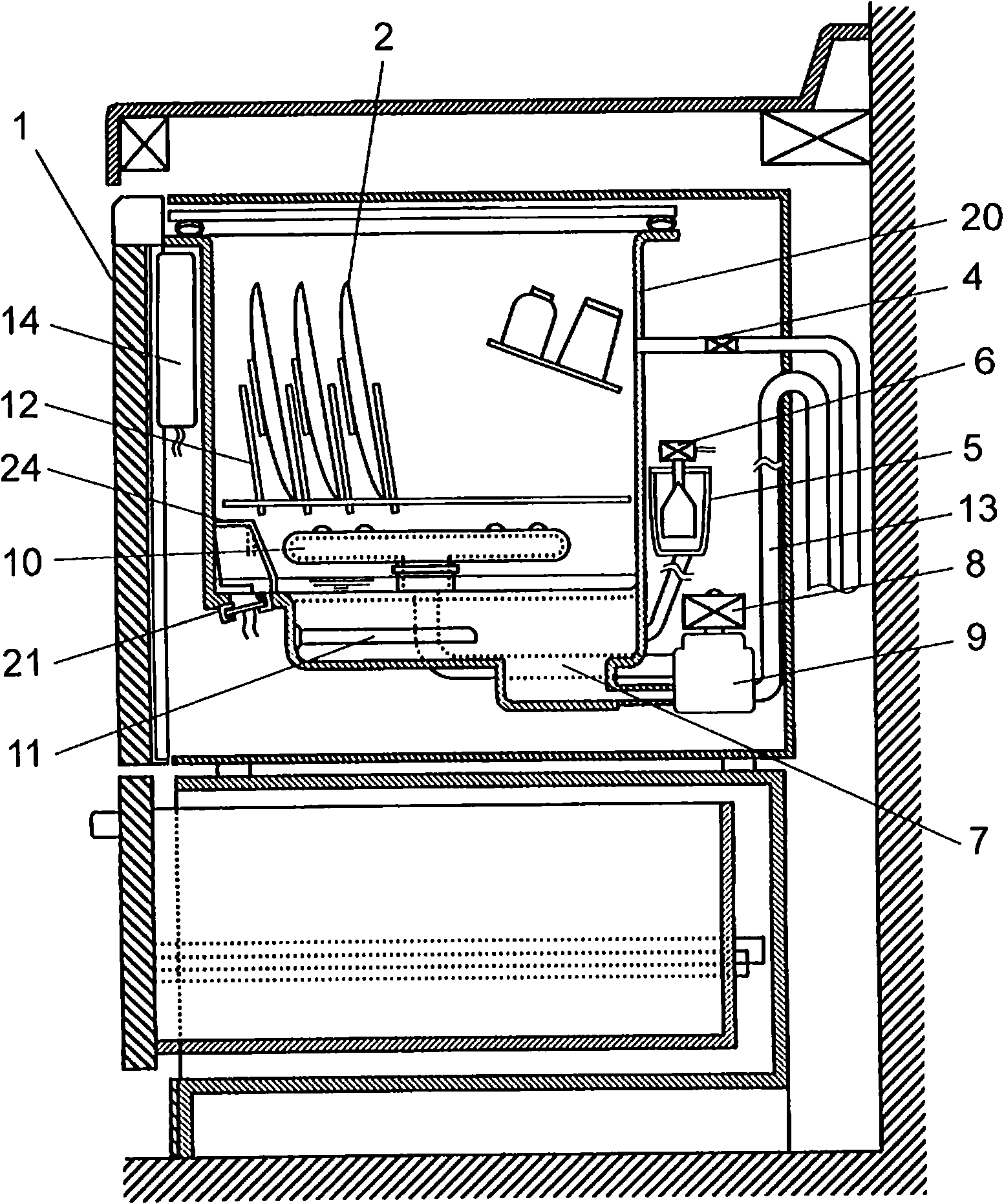

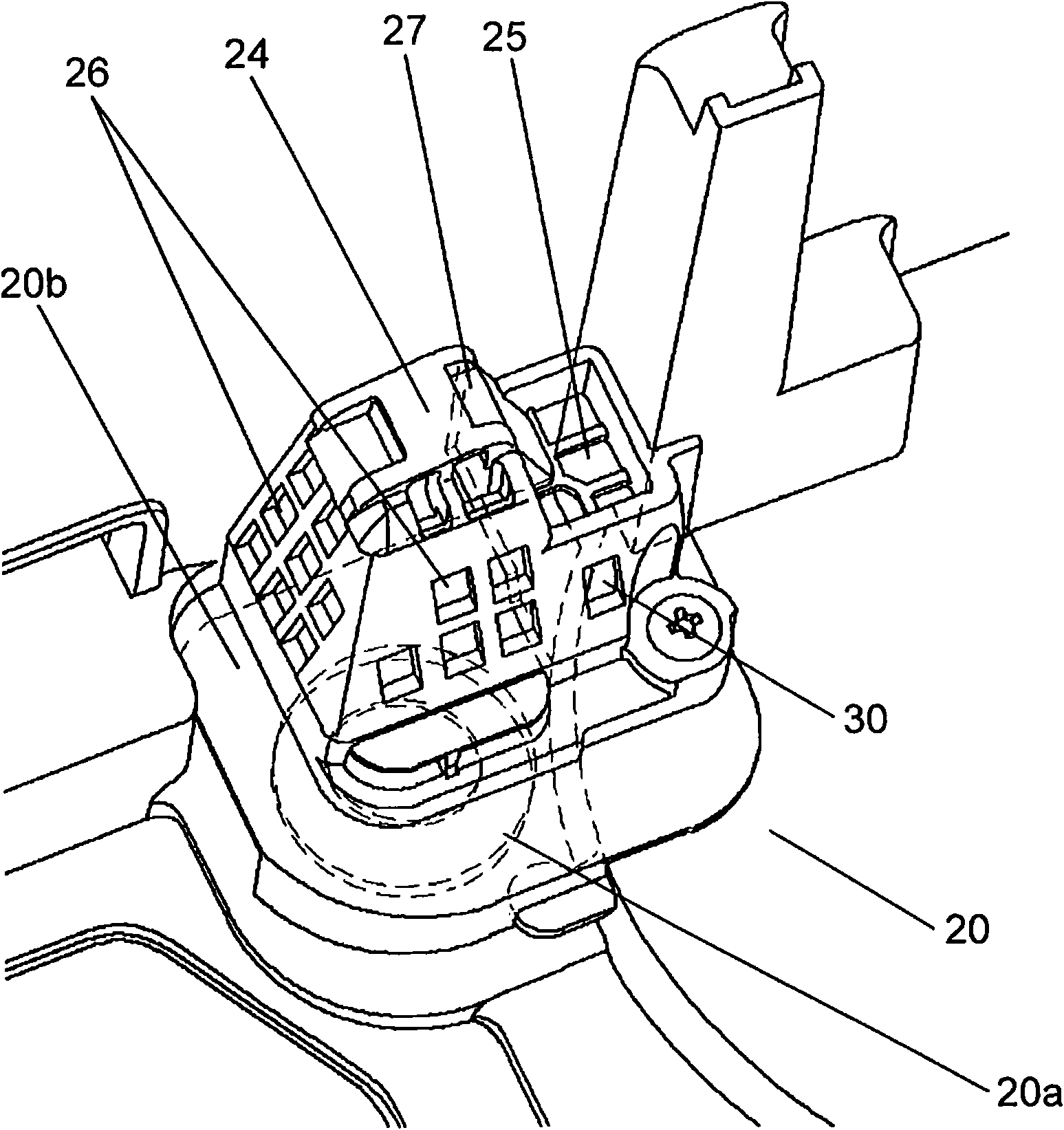

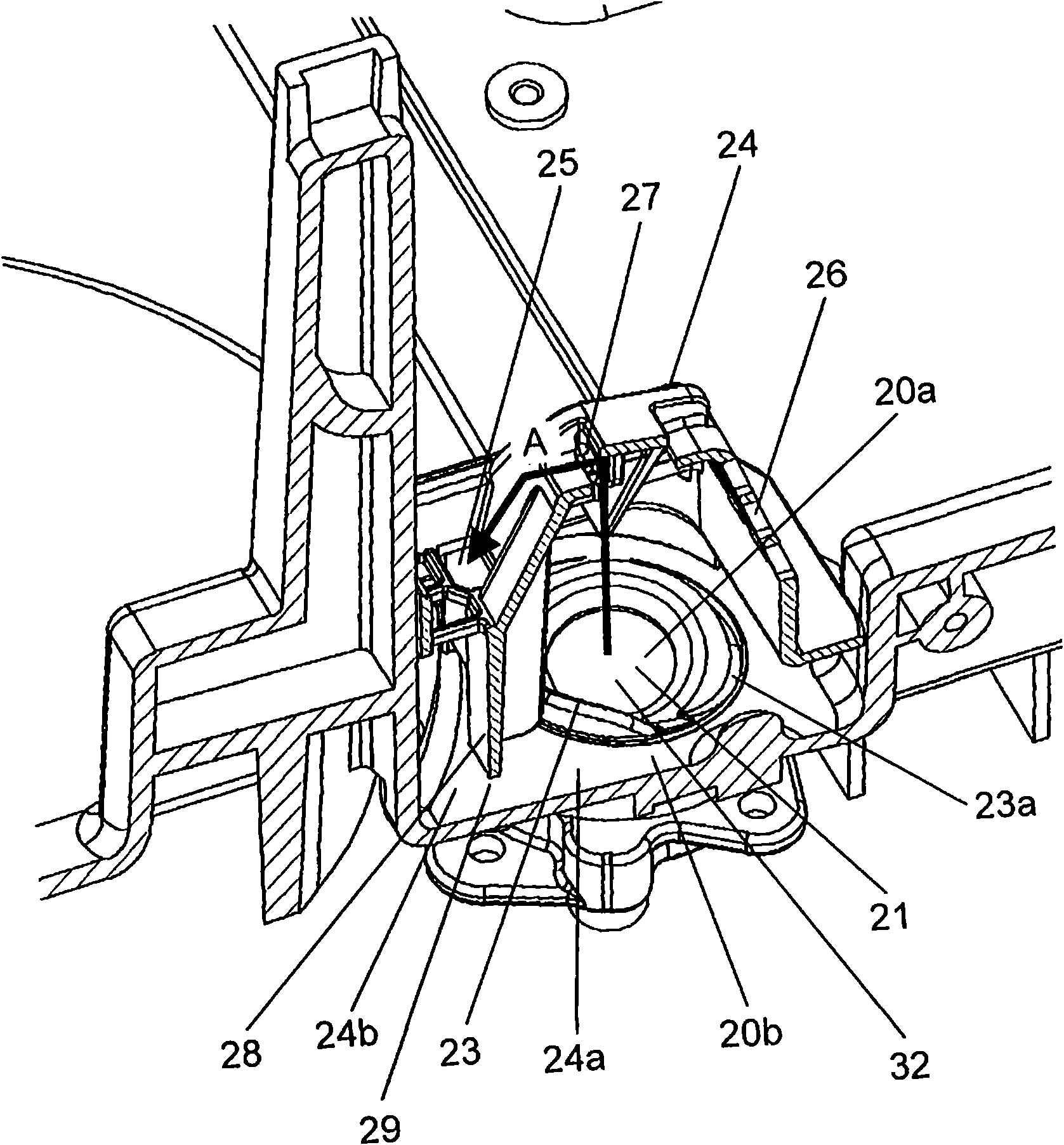

[0023] figure 1 It is a vertical cross-sectional view of the dishwasher according to the embodiment of the present invention seen from the right side. figure 2 It is a perspective view of main parts of the dishwasher viewed from the rear side. image 3 It is a cutaway perspective view of the main part of the dishwasher. Figure 4 It is a longitudinal sectional view of main parts of the dishwasher. Figure 5 It is a top view of the main part of the dishwasher.

[0024] This embodiment has a mist generating part, that is, has a structure in which an ultrasonic vibrator and peripheral components are assembled in the bottom of the washing tank of the dishwasher. The overall structure and operation of the dishwasher are the same as those of conventional dishwashers. In the case of the dishwashing machine with the atomization generation part of the present invention, the atomization process of the high-concentration detergent liquid carried out by the atomization generation pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com