Method for dismounting sealing opening of rotor vane of low-pressure coal press machine of power plant

A technology of rotor blades and coal compressors, which is applied in the field of dismantling of rotor blade seals of low-pressure coal compressors in power plants. It can solve problems such as low efficiency, long equipment repair cycle, and increased equipment disassembly workload, so as to ensure normal operation and shorten maintenance. Cycle time and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

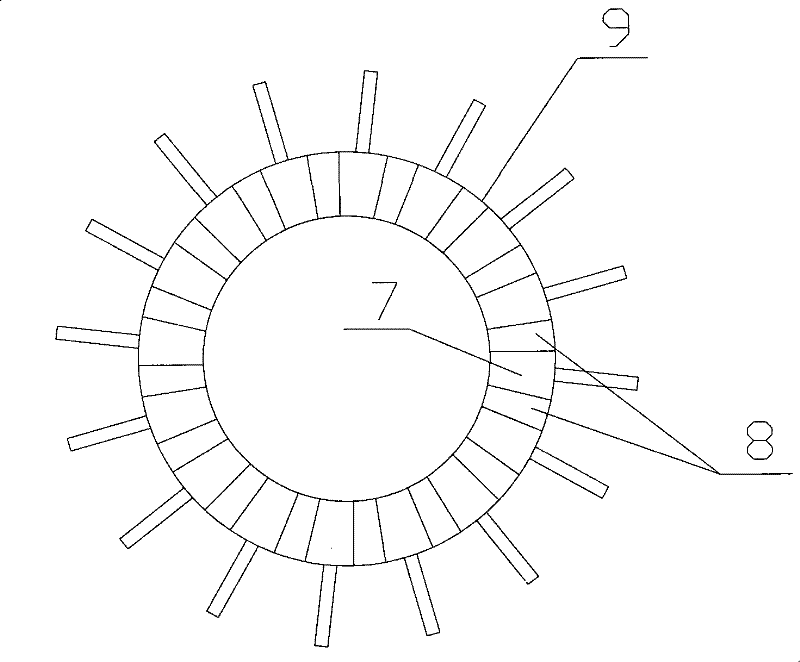

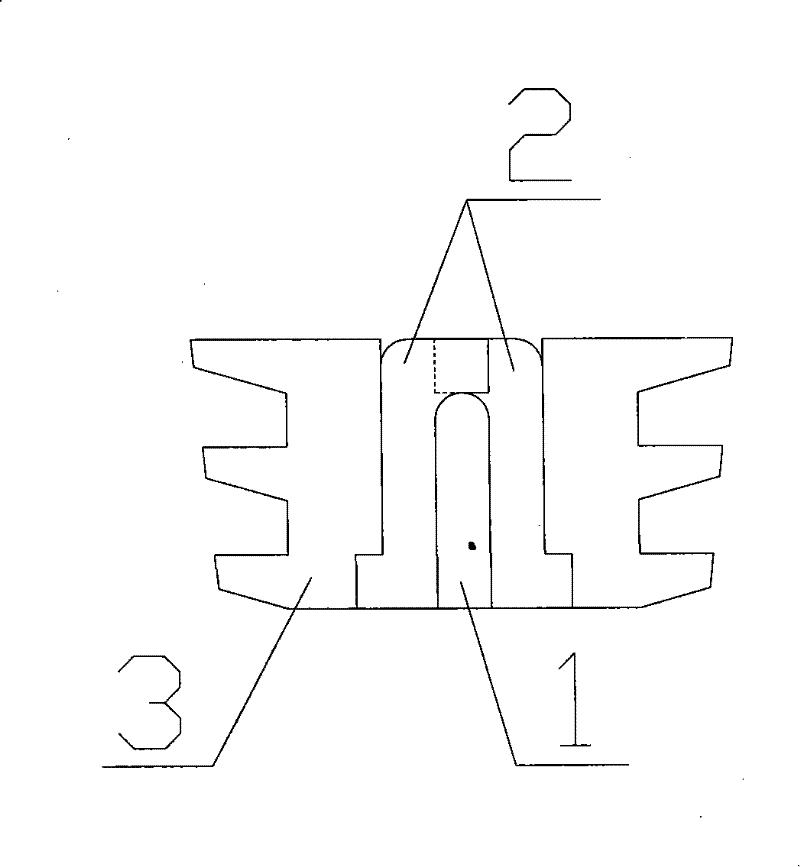

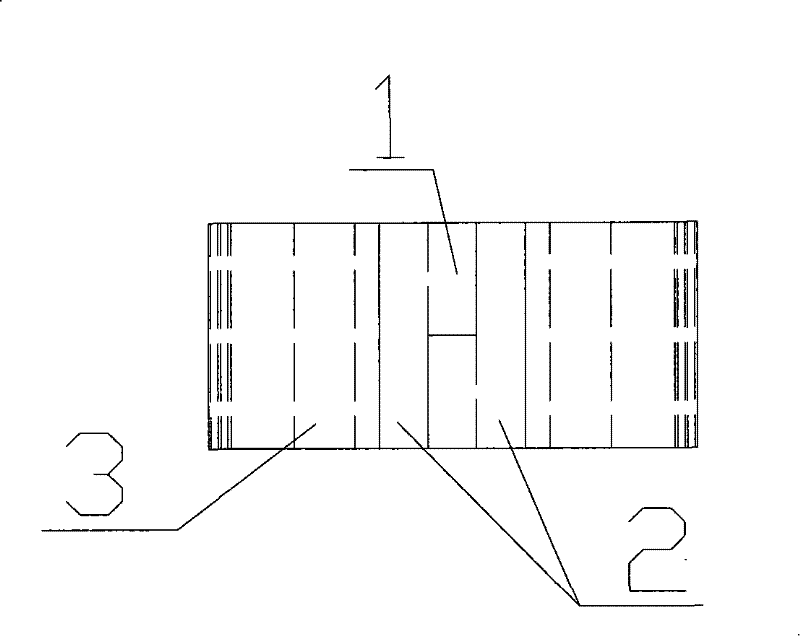

[0017] In the present invention, the seal of the rotor blade of the low-pressure coal compressor of the power plant is composed of an intermediate clip, two safety pressing sheets positioned on both sides of the intermediate clip, and a vertical tree-shaped blade root positioned outside the two safety pressing sheets. To seal the seal, the two safety pressing pieces must be ground and turned up first, then the middle clip is pulled out, and then the left and right safety pressing pieces are taken out, and then the two vertical tree-shaped leaf roots can be removed, and finally the leaves can be taken out. The thickness of the intermediate clip is 4mm. If the M4 screw hole is processed, drilling and tapping are more difficult, and the pulling force of the M4 screw is not enough. However, when processing M5 screw holes, some threads are on the left and right insurance pressure pieces;

[0018] Therefore, the technical point of removing the seal is to grind the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com