Indirect test method for explosion-proof pressure of metal battery shell

A metal battery and explosion-proof pressure technology, which is applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of high explosion-proof pressure test value, damage, and rubber pads that cannot be used universally, so as to achieve a clean test environment and good test repeatability , the effect of fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

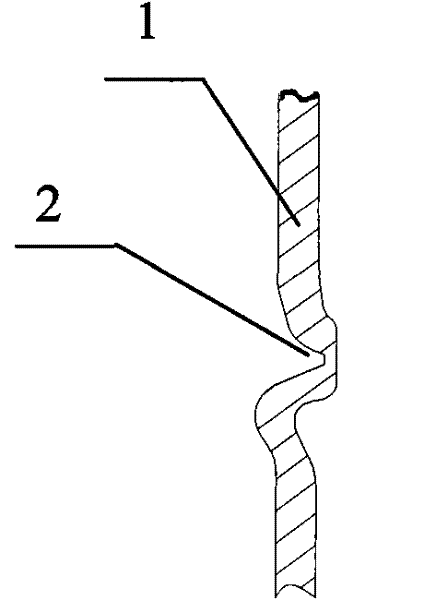

[0037] figure 1 It is a schematic cross-sectional view of the explosion-proof valve. A notch 2 is usually processed on the lithium-ion metal battery case 1 as an explosion-proof valve. At present, the shape of the explosion-proof valve is mainly linear.

[0038] Hereinafter, the test method of the present invention will be described in detail by taking the indirect test method of the explosion-proof pressure of the direct explosion-proof 463446 metal battery case as an example.

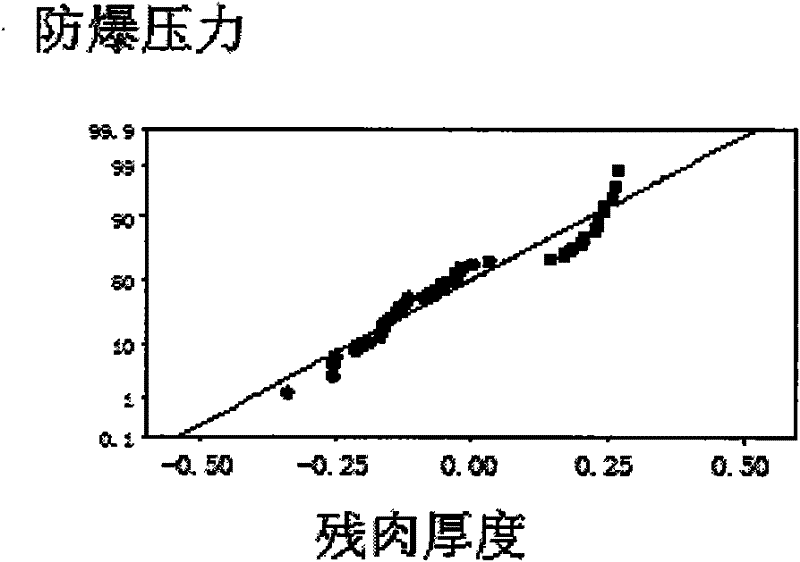

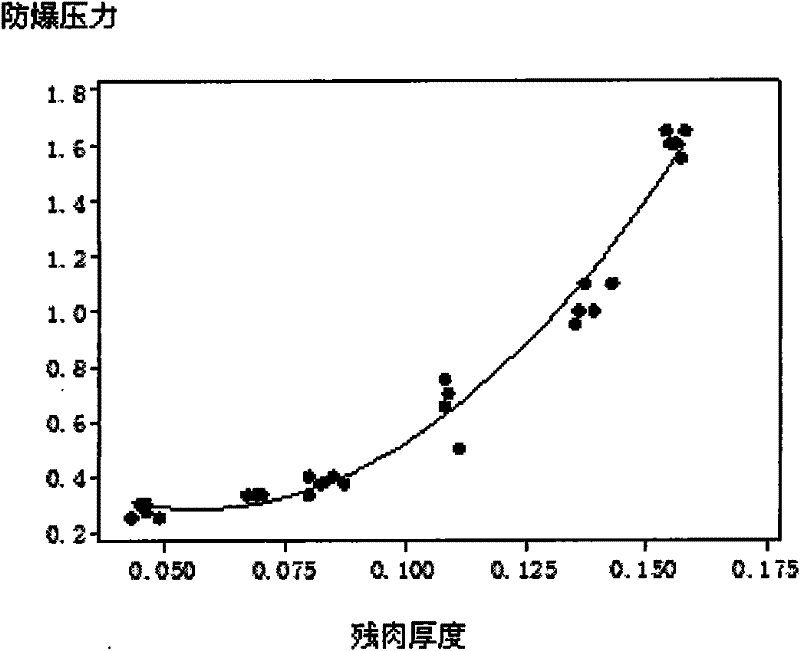

[0039] From the straight explosion-proof 463446 aluminum battery case samples provided by a battery case manufacturer, 6 groups of 463446 battery case samples with different thickness of residual meat were taken, and 10 samples were taken for each group. The thickness of the remaining meat of the explosion-proof valve was measured for these 60 battery cases, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com