Method and device for on-line withstand voltage detection of film sintered electromagnetic wire

A technology of withstand voltage detection and electromagnetic wire, which is applied in the direction of measuring devices, material breakdown voltage, and measuring electricity, can solve the problem that the detection results cannot truly reflect the product quality level, and cannot fully detect the weakness of the bare wire burr film insulation, sample Small space and other issues, to achieve the effect of convenient online remote monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

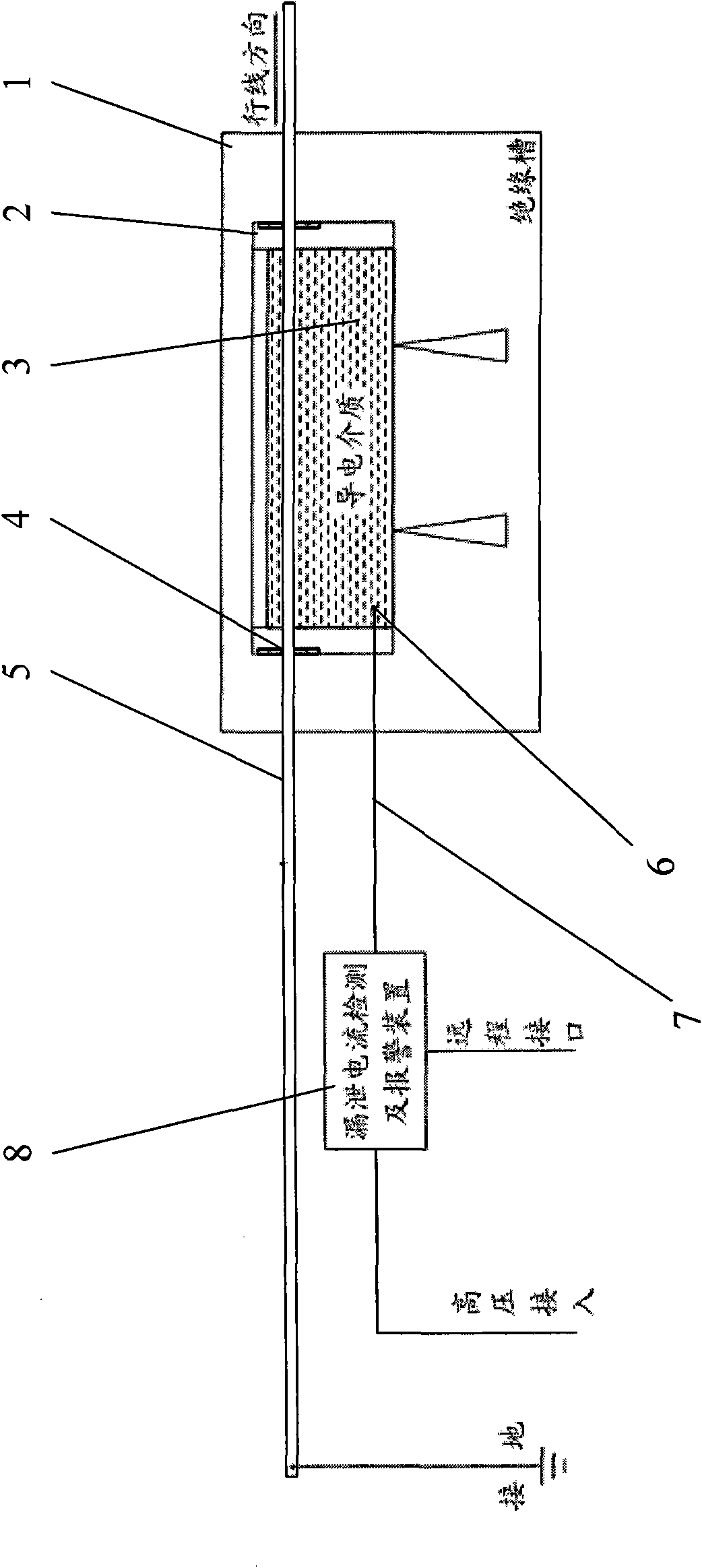

[0013] Such as figure 1 As shown in the figure, an online withstand voltage detection method in the process of film sintering electromagnetic wire is provided. An insulating groove is arranged at the outgoing end of the film sintering electromagnetic wire, and a conductive liquid medium (such as conductive medium water, ethanol, etc.) is installed in the groove. After the film is sintered, the The electromagnetic wire passes through the conductive liquid medium in the insulating tank; the wire before wrapping and sintering is used as the ground electrode, and the high voltage is connected to the conductive liquid medium, thereby forming a voltage on both sides of the electromagnetic wire insulation; and drawn out from the conductive liquid medium Leakage current detection and alarm device, the leakage current detection and alarm device is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com