Ultrasonic energy transducer with continuously changed acoustic impedances

An ultrasonic transducer and acoustic impedance technology, applied in ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, infrasonic diagnosis, etc., can solve the problem of increasing the complexity of ultrasonic transducers, reducing the performance of ultrasonic transducers, and inability to transmit energy, etc. problems, to achieve good acoustic matching effect, multi-layer structure simplification, and the effect of reducing multiple reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

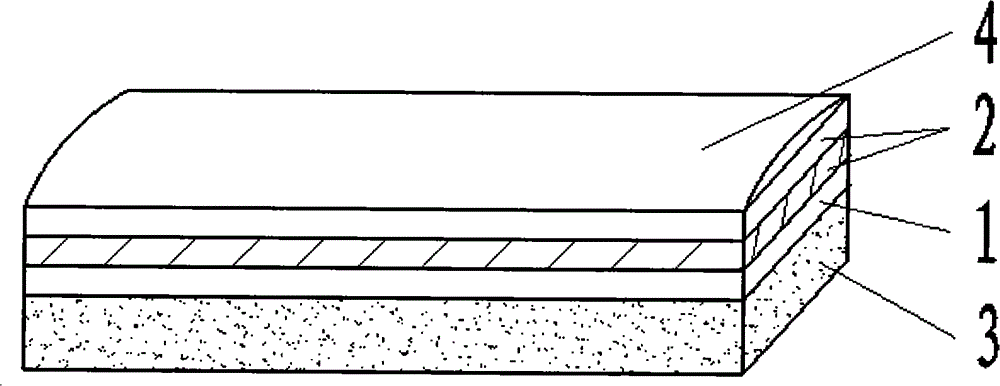

[0038] An ultrasonic transducer with continuously changing acoustic impedance comprises a backing and a piezoelectric material layer which are stacked in sequence, and is characterized in that a layer with continuously varying acoustic impedance is provided between the piezoelectric material layer and the working medium.

[0039] The acoustic impedance continuously changing layer is formed by mixing and solidifying acoustic material particles with the same particle size and different specific gravity and polymer coupling agent.

[0040] Acoustic impedance value Z of the surface adjacent to the layer of continuous acoustic impedance change and the piezoelectric material layer H It is equal to the acoustic impedance value of the piezoelectric material layer, and the acoustic impedance value Z of the surface adjacent to the working medium of the continuous acoustic impedance change layer l It is equal to the acoustic impedance value of the working medium.

Embodiment 1

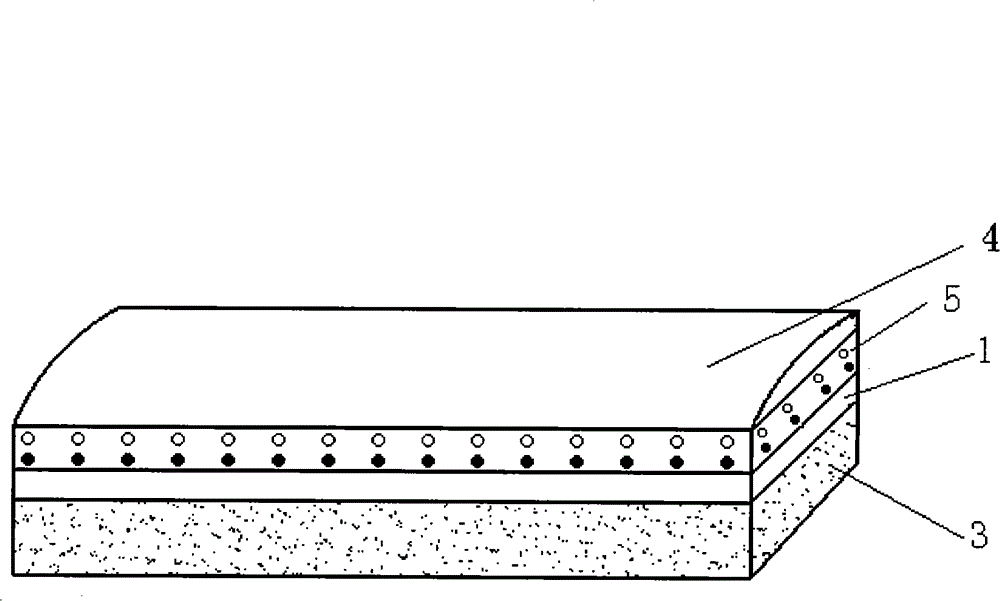

[0042] In this embodiment, the ultrasonic transducer is not in direct contact with the working medium, and a lens layer is added.

[0043] see figure 2 , an ultrasonic transducer with continuously varying acoustic impedance, comprising a backing 3 , a piezoelectric material layer 1 , a continuously varying acoustic impedance layer 5 and a lens layer 4 which are stacked in sequence.

[0044] The acoustic impedance continuously changing layer 5 is formed by mixing and solidifying acoustic material particles with the same particle size and different specific gravity and polymer coupling agent.

[0045] To prepare a non-conductive acoustic impedance continuously variable layer 5, the piezoelectric material layer 1 can be selected as the material of the high impedance end of the acoustic impedance continuously variable layer 5, and its acoustic impedance value is ZH , select the hollow non-metallic material as the material of the low impedance end of the acoustic impedance continu...

Embodiment 2

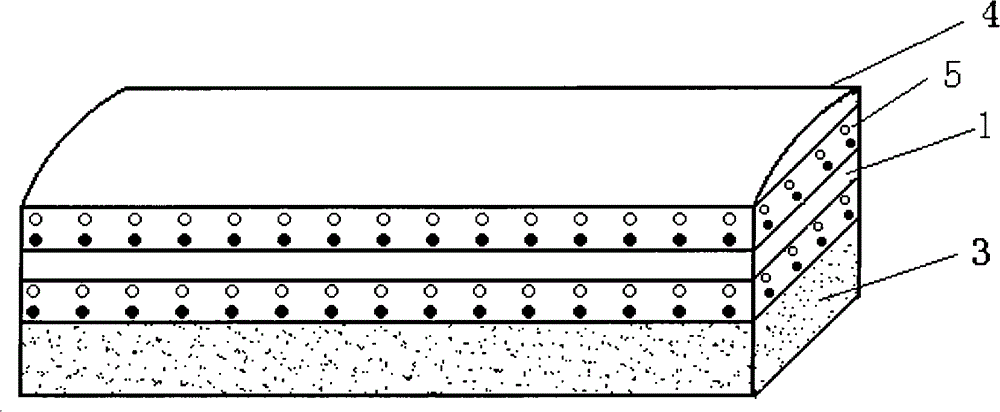

[0053] see image 3 The difference between the second embodiment and the first embodiment is that a material layer with continuously changing acoustic impedance is also arranged between the backing 3 and the piezoelectric material layer 1, and the surface of the material layer with continuously changing acoustic impedance is adjacent to the backing 3 The acoustic impedance value of is equal to the acoustic impedance value of the backing 3, and the acoustic impedance value of the surface of the continuously changing acoustic impedance material layer adjacent to the piezoelectric material layer 1 is equal to the acoustic impedance value of the piezoelectric material layer 1. Similarly, the acoustic impedance of the continuously changing acoustic impedance material layer is continuously distributed along the longitudinal direction, the preparation method of the continuously changing acoustic impedance material layer is the same as the preparation method of the continuously changin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com