Method and device for the entrained-flow gasification of solid fuels under pressure

A solid fuel and entrained bed technology, applied in fixed bed gasification, mechanical details of gasification devices, granular/powder fuel gasification, etc., can solve problems such as technical infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

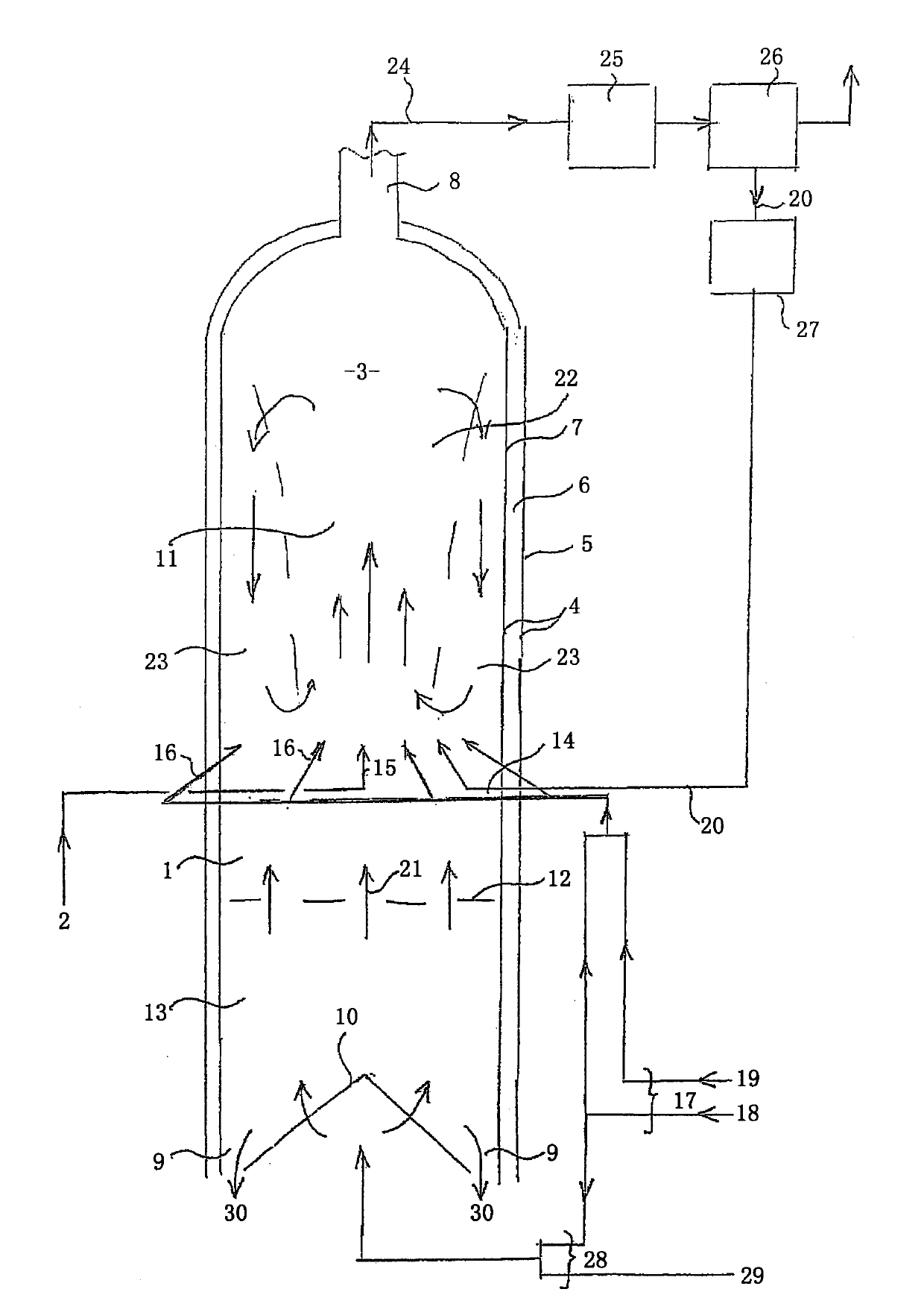

[0039] figure 1A gasification reactor 1 with an internal circulating entrained flow bed is shown in a highly simplified diagram. The gasification chamber 3 of the gasification reactor 1 for entrained bed gasification is surrounded by a cylindrical pressure vessel 4 consisting of an outer pressure jacket 5 , a water chamber 6 and an inner jacket 7 . The inner casing 7 is added stud material and plated with refractory material as a ceramic protective cover. The feed gas outlet 8 is located at the upper end of the entrained bed gasifier 1 and the bottom product outlet 9 is located at the lower end, wherein only the upper profile of the rotary grate 10 is shown in the figure. An entrained bed 11 of internal circulation is formed above the surface 12 of a moving bed 13 . On the plane 14 of about 1 meter height above the surface 12 of the moving bed 13, two dense phase flow introduction feed nozzles 15 for powdery dry lignite 2 and 6 for inputting the first gas are arranged to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com