Coating liquid for electrophotographic photosensitive body, electrophotographic photosensitive body, and electrophotographic photosensitive body cartridge

An electrophotography and photoreceptor technology, applied in optics, electrography, instruments, etc., can solve the problems of high crystallinity, poor solution stability, insufficient solution stability, etc., and achieve excellent liquid stability and excellent mechanical durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

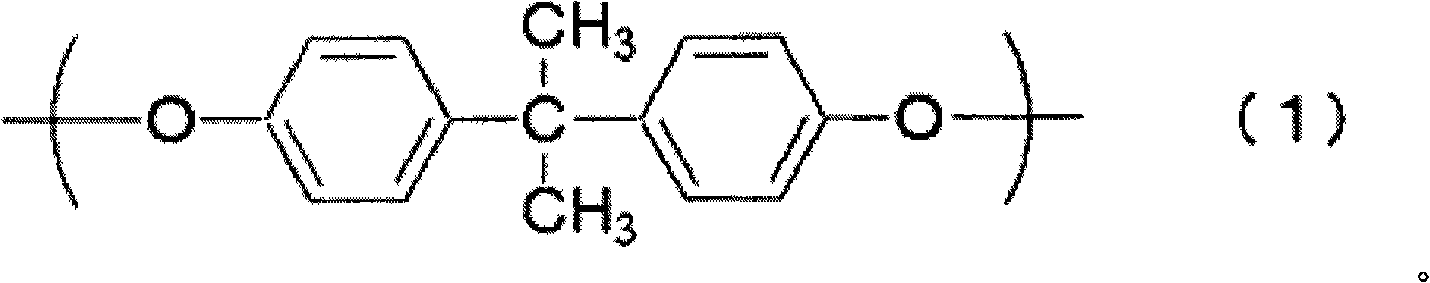

[0075] As the preparation method of polycarbonate resin, the method of (3) is often used. First, an oligomer of 1 monomer to dozens of monomers (weight body) is formed by polymerizing bisphenol monomers, and then the low polymer is further polymerized polymers to prepare desired polycarbonate resins. When synthesizing a copolymer, it can be performed by polymerizing two types of oligomers. When this production method is employed, a unit sequence (block) formed of the same bisphenol unit is formed at the time of oligomer synthesis. This copolymer is called a block copolymer.

[0076] Since the copolymerized polycarbonate resin of the present invention has the repeating structure shown in the formula (1) of the present invention, it has the characteristics of easy crystallization, and the repeating structure shown in the formula (1) of the present invention repeats as a block structure When , crystallization is more likely to occur, so it is preferable to have less block struc...

Embodiment

[0189] Hereinafter, the present invention will be described more specifically based on examples. The following examples are merely examples for explaining the present invention in detail, and the present invention is not limited to the following examples within the scope not exceeding the gist thereof. In addition, description of "parts" in the following Examples, Comparative Examples, and Reference Examples means "parts by weight" unless otherwise specified.

[0190]

[0191] First, the measurement of the viscosity average molecular weight will be described.

[0192] The polycarbonate resin was dissolved in dichloromethane to prepare a solution having a concentration C of 6.00 g / L. Flow time t using solvent (dichloromethane) 0 The flow-down time t of the sample solution was measured in a constant temperature water bath set at 20.0° C. with an Ubbelode capillary viscometer of 136.16 seconds. The viscosity average molecular weight Mv was calculated from the following formu...

manufacture example

[0199] 100 parts (0.438mol) of 2,2-bis(4-hydroxyphenyl)propane (called bisphenol A), 45.6 parts (1.14mol) of sodium hydroxide, 848 parts of water, 0.336 parts of sodium bisulfite, two A mixture of 432 parts (325 mL) of methyl chloride was placed in a reaction tank equipped with a stirrer and stirred. The temperature of the reaction tank was maintained between 0°C and 10°C, and 110 parts (1.11 mol) of carbonyl chloride was blown thereinto for about 6 hours to perform a reaction. After the reaction, only the dichloromethane solution containing polycarbonate oligomers was collected. The analysis results of the dichloromethane solution of the obtained oligomer are as follows.

[0200] Oligomer concentration (Note 1): 21.9% by weight

[0201] Terminal chloroformate group concentration (Note 2): 0.420 equivalent

[0202] Terminal phenolic hydroxyl concentration (Note 3): 0.026 equivalent

[0203] (Note 1): The solution was evaporated to dryness for measurement.

[0204] (Note 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com