Portable high-strength blow-molded plastic

A high-level, blow molding technology, applied in the direction of connecting components, furniture parts, sports accessories, etc., can solve the problem of table inequality, achieve the effect of increasing strength, output and/or production efficiency, and saving materials and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

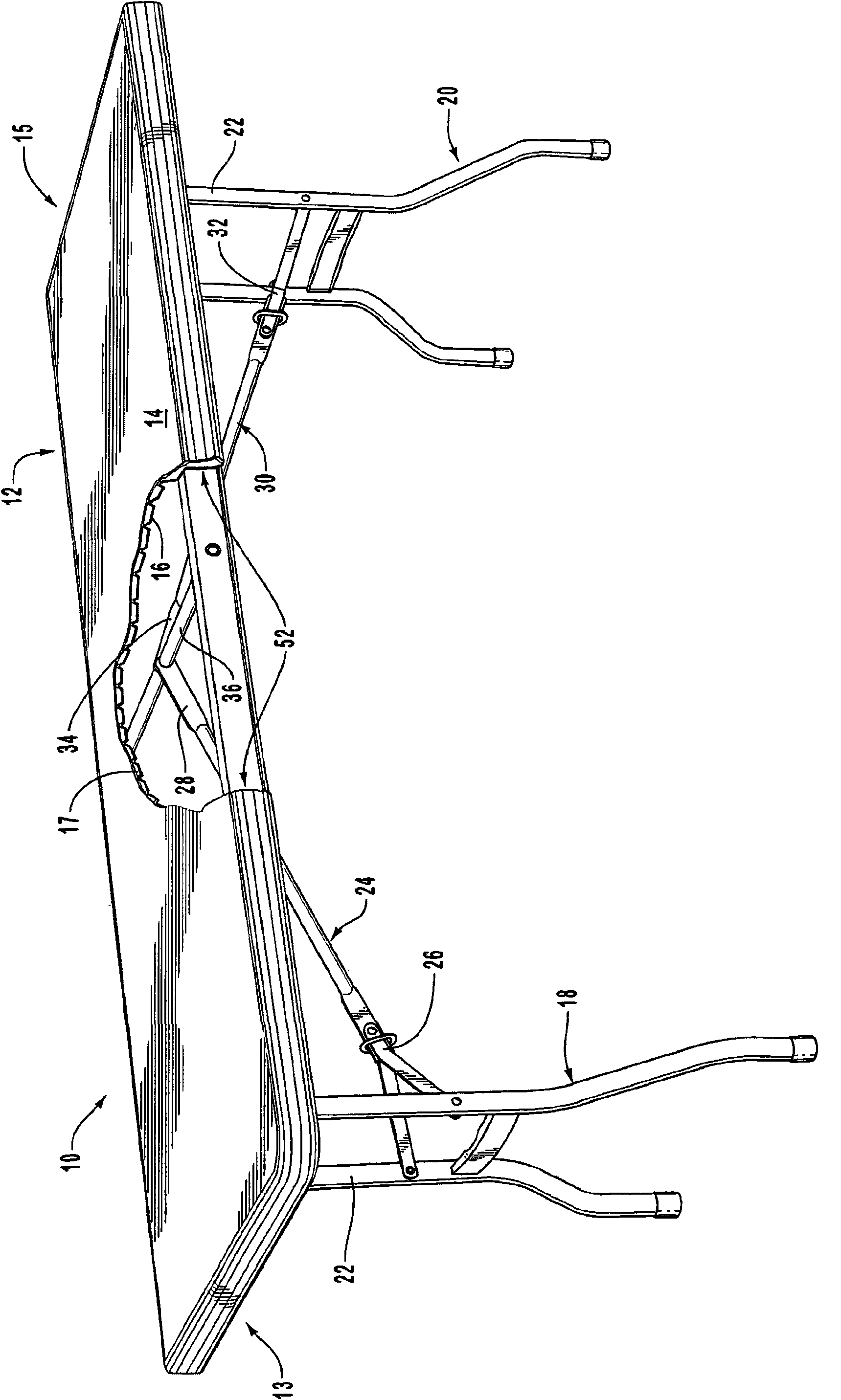

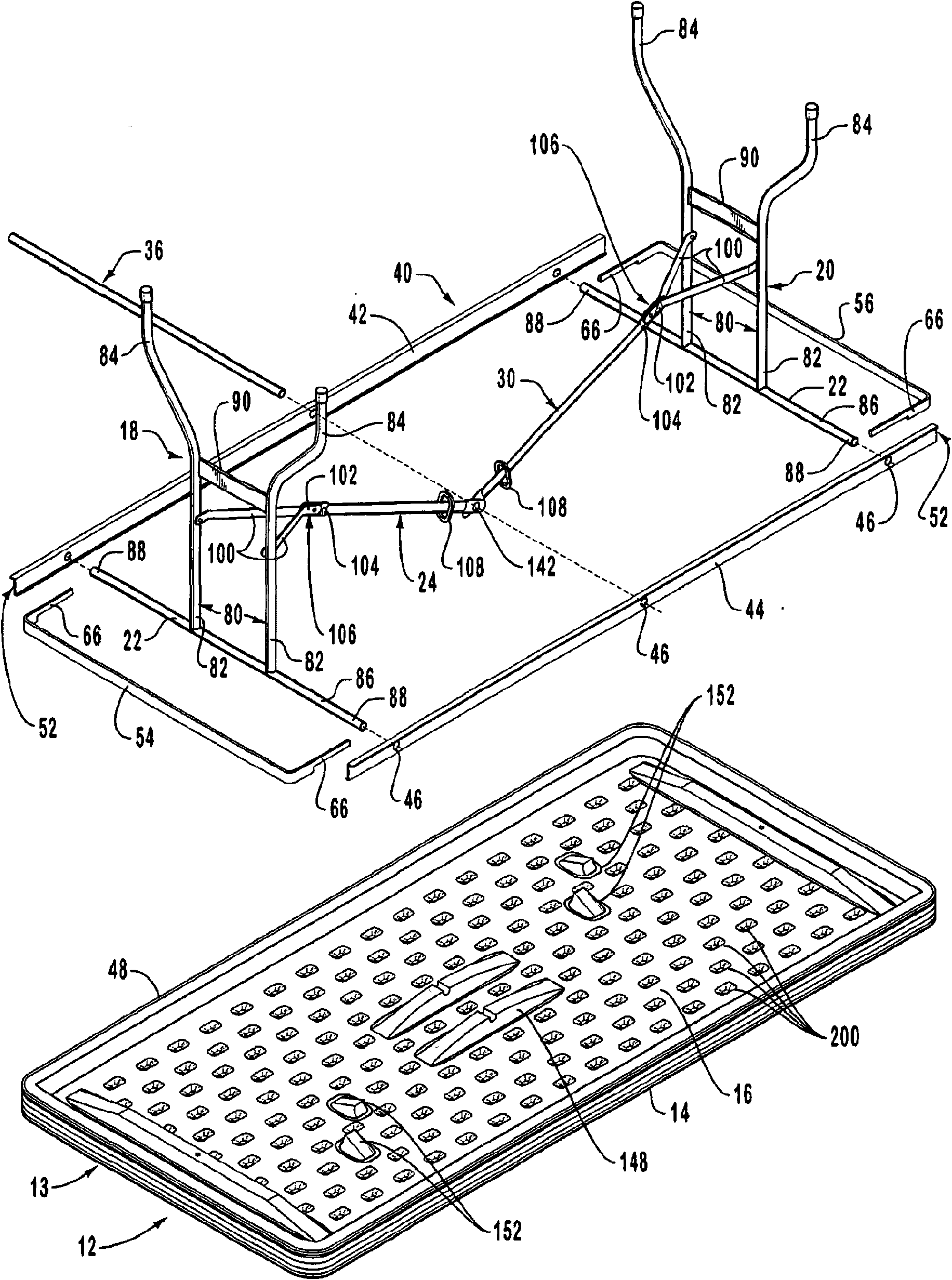

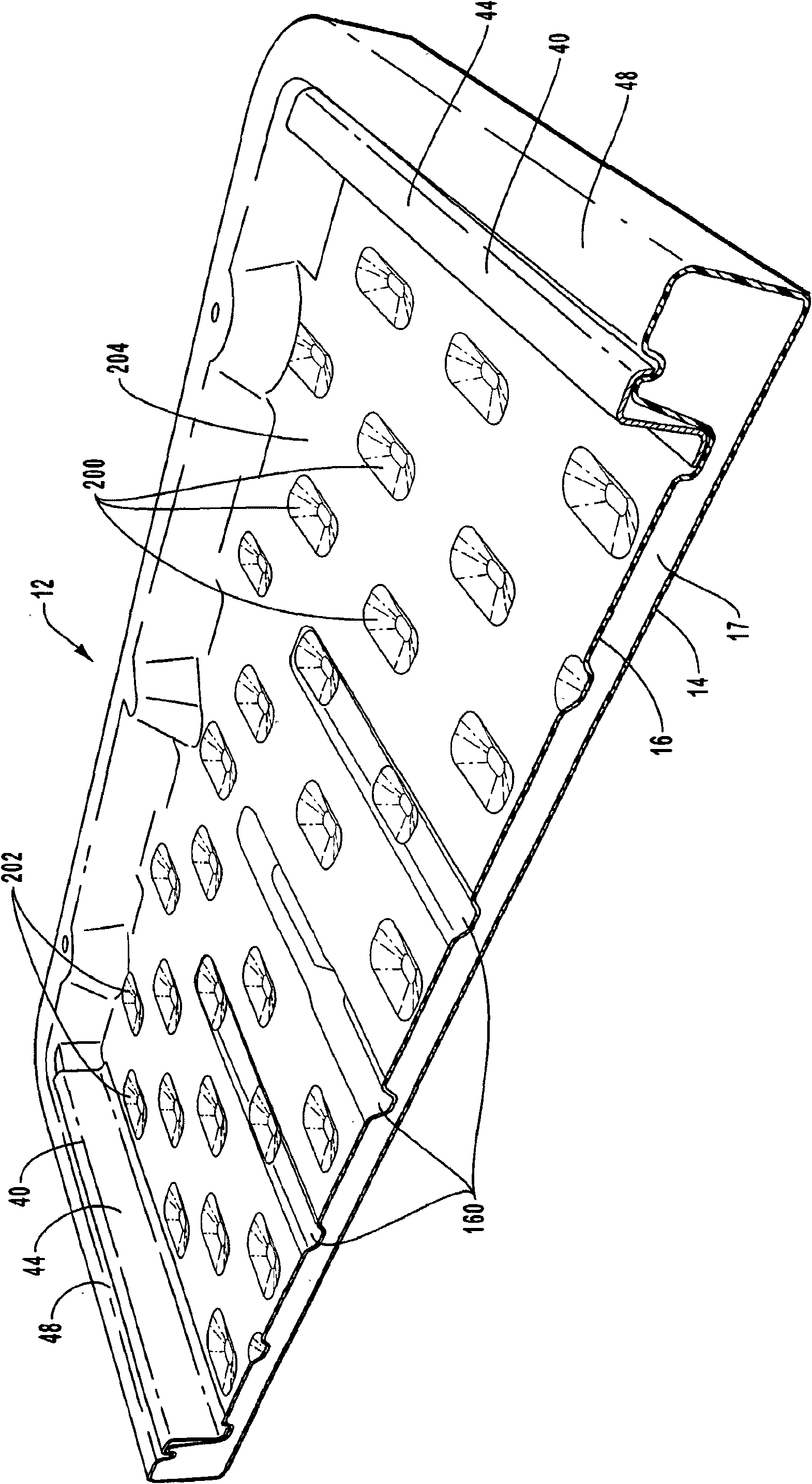

[0032] The present invention relates to increased strength and / or lighter weight blow molded structures. However, the crux of the invention is not limited to blow-molded structures for increased strength and reduced weight. As disclosed, the blow molded structures disclosed herein can be successfully used in connection with other types of blow molded structures that do not have added strength or are not lightweight.

[0033] In addition, terms such as top, bottom, front, rear, right, and left are used to describe the accompanying drawings to help describe blow molding structures. However, it is worth noting that blow molded structures can be placed in a variety of orientations, including various angles, sideways and even upside down. A detailed description of the high-strength and / or lightweight blow-molded structures follows:

[0034] like Figure 1A table 10 having a table top 12 made by blow molding is one embodiment of a blow-molded structure that can be made into high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com