Device and method for reducing foam

A foam and container technology, applied in the field of foam treatment, can solve problems such as product quality decline, environmental pollution, finished product gaps, etc., and achieve the effect of reducing the amount of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

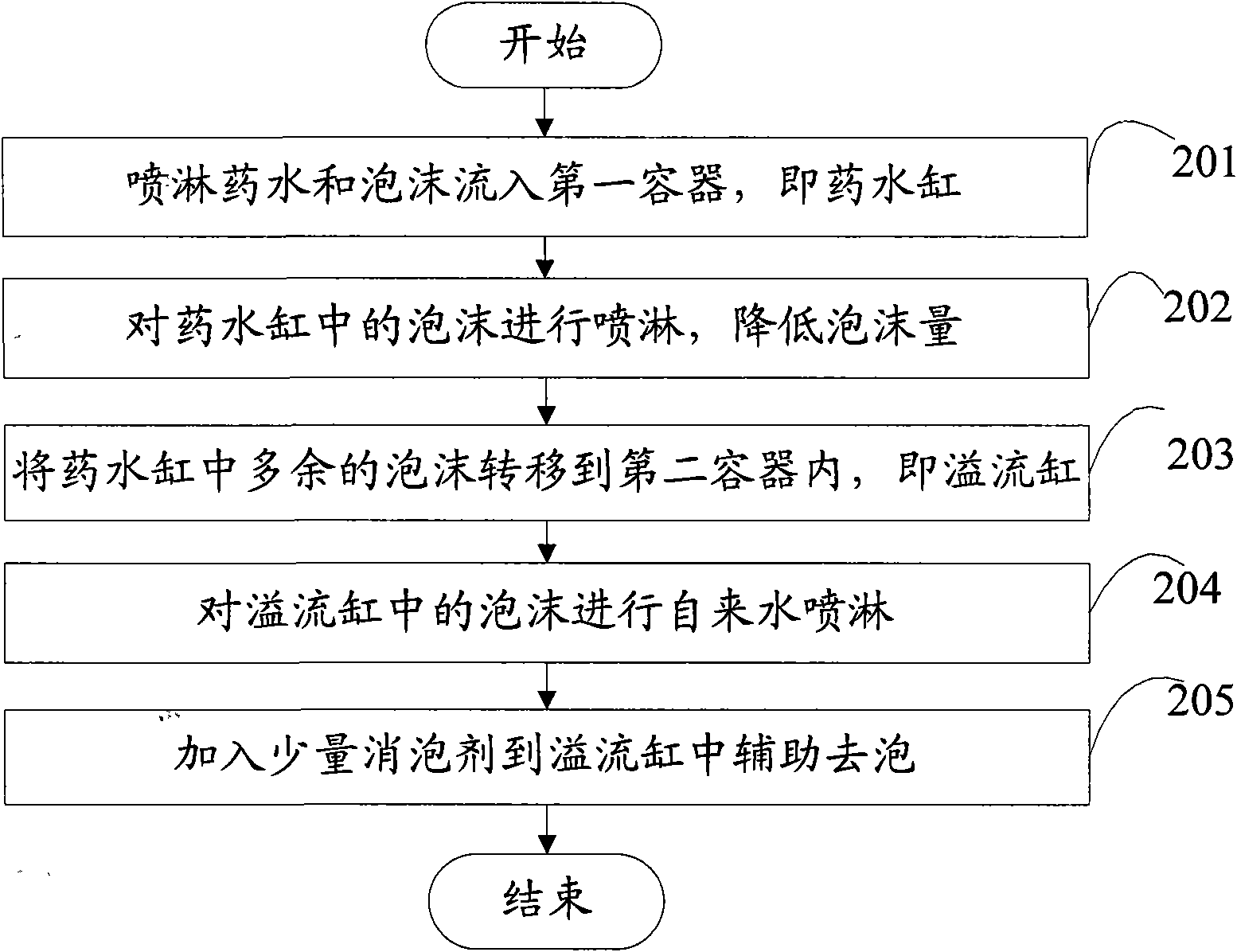

[0016] The embodiment of the present invention aims to provide a device for reducing foam, which reduces the amount of foam by directly spraying liquid onto the foam on the liquid surface, or transfers most of the foam through the second container to reduce the amount of foam. Therefore, the present invention implements For example, it is not necessary to use defoamer to reduce the amount of foam; but when there is too much foam, it is only necessary to add a small amount of defoamer to the second container to assist defoaming, which reduces the consumption of defoamer and saves costs.

[0017] The following will be described in conjunction with the accompanying drawings and specific embodiments.

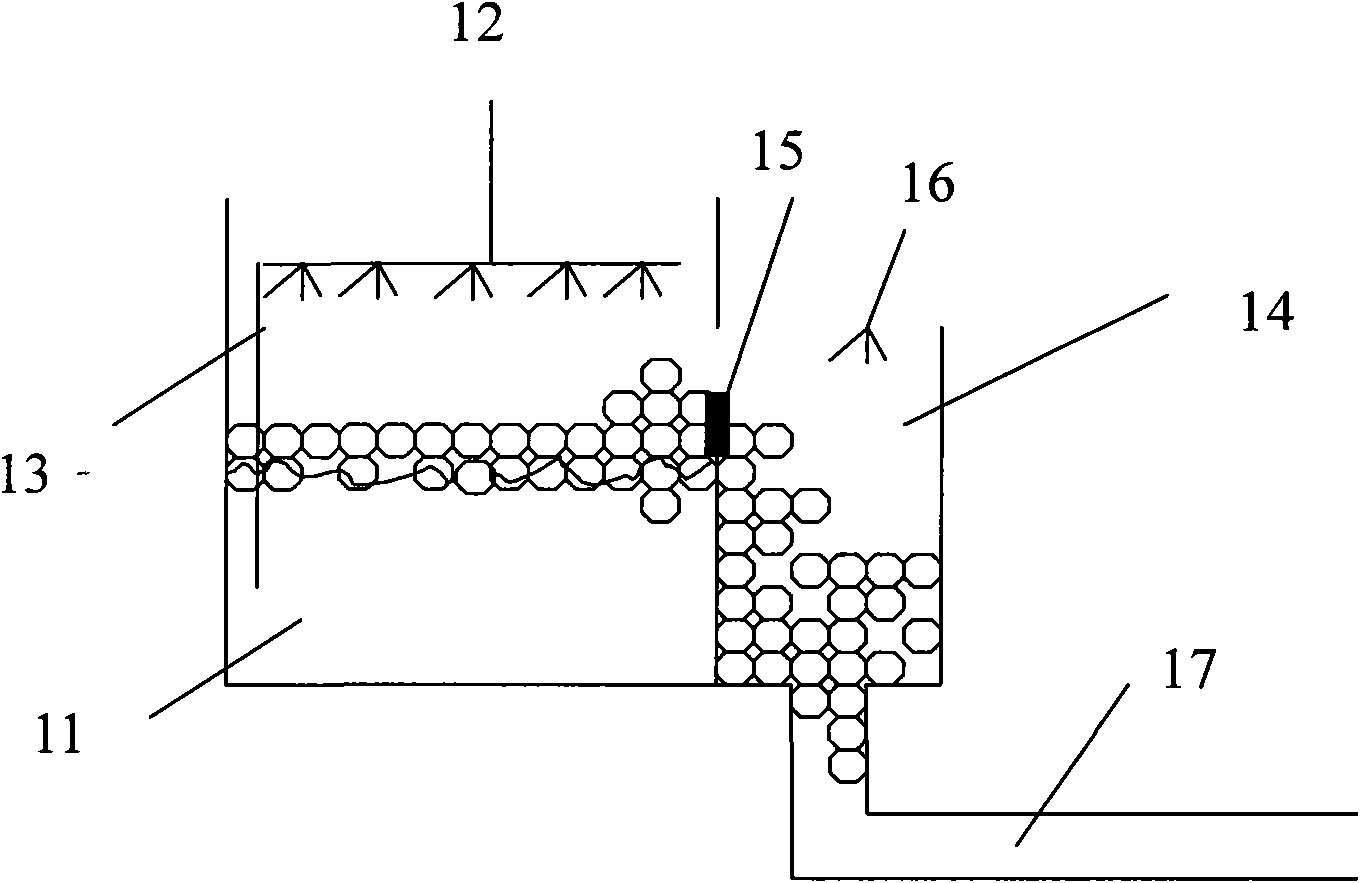

[0018] Such as figure 1 As shown, the device for reducing foam according to the embodiment of the present invention includes a first container 11 containing foam, and a first spray pipe 12 is arranged at the upper end of the first container 11 .

[0019] In the embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com