Application of collecting agent in reverse floatation of bauxite

A collector and bauxite technology, applied in flotation, solid separation, etc., can solve problems such as constraints, and achieve the effects of small foam volume, good foam mineralization effect, and good selection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The pure minerals of diaspore and kaolinite were tested by the method of the invention.

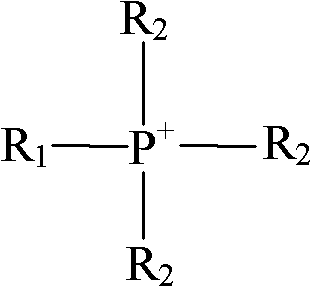

[0023] The single mineral flotation experiment was carried out on the XFG hanging cell flotation machine. Weigh 2g of minerals each time into a 40ml flotation tank, add 30ml of distilled water, adjust the slurry for 1min, adjust the pH value with HCl or NaOH for 3min, measure the pH value with a PHS-3C precision pH meter, add quaternary phosphorus salt and stir 3 minutes, 4 minutes of flotation. The flotation process adopts manual foam scraping. After the flotation is completed, the scraped foam (concentrate) is dried, weighed, and the recovery rate is calculated.

[0024] After adopting the method, it can be obtained that the recovery rate of the new collector for kaolinite in the range of pH=5-7 is above 90%, while the recovery rate of diaspore is below 50%.

Embodiment 2

[0026] Using this method, a bauxite with an aluminum-silicon ratio of 5-5.5 in Henan was tested for flotation.

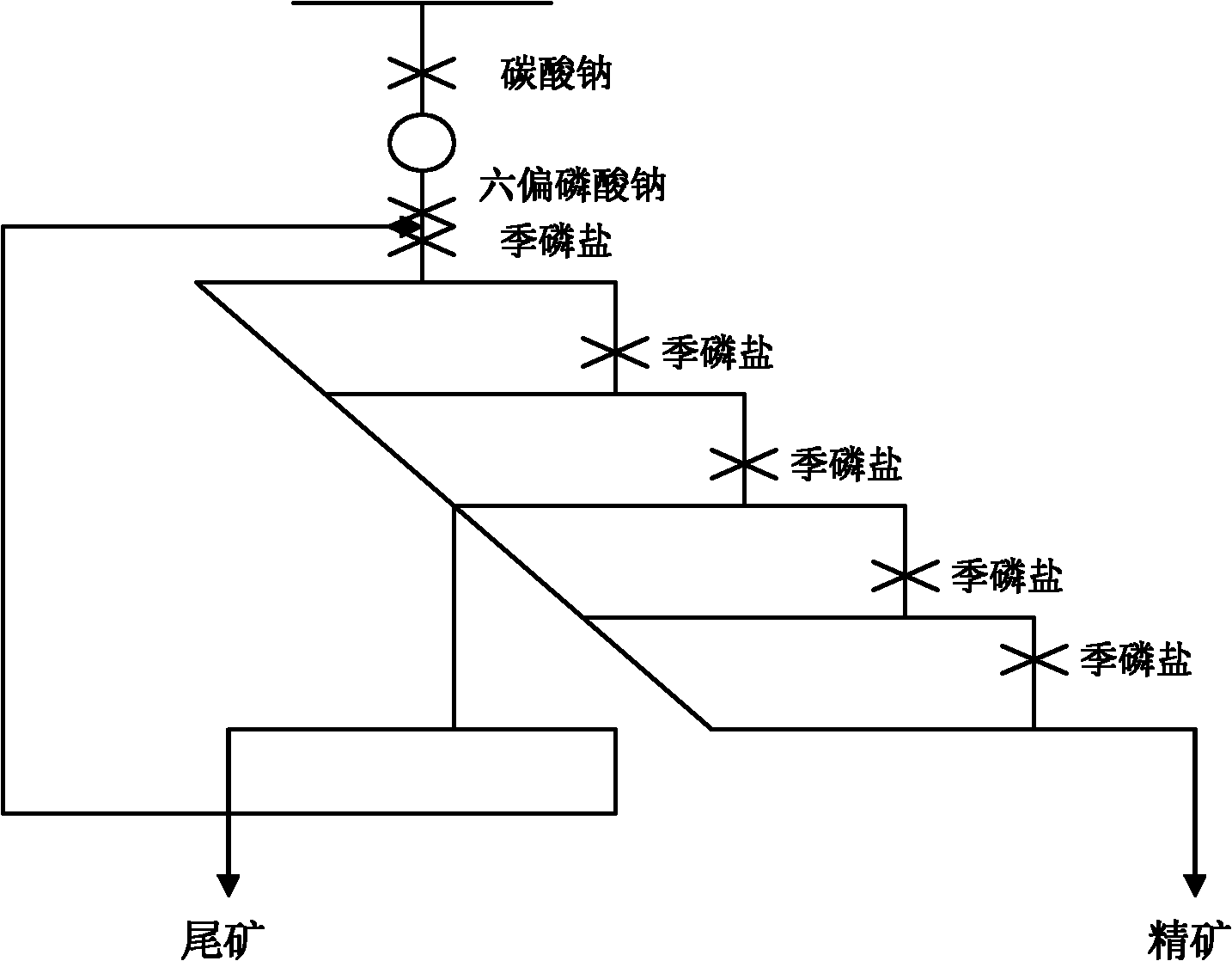

[0027] Grind the bauxite to -0.074mm, accounting for 88%, add 1000 g / t of sodium carbonate during the grinding process; then add 200 g / t of water glass or 60 g / t of sodium hexametaphosphate as inhibitor and collector The quaternary phosphorus salt is 100g / t, and the rough separation is carried out, and then the chemical agent is gradually reduced for 4 times of separation to obtain the concentrate.

[0028] After adopting this method, Al can be obtained 2 o 3 The recovery rate is 88%, and the aluminum-silicon ratio is greater than 8 concentrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com