Vehicle three-way catalytic converter cleaning agent and preparation method thereof

A three-way catalyst and cleaning agent technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problem of not being able to cool down in time, reduce water consumption, have good biodegradability, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

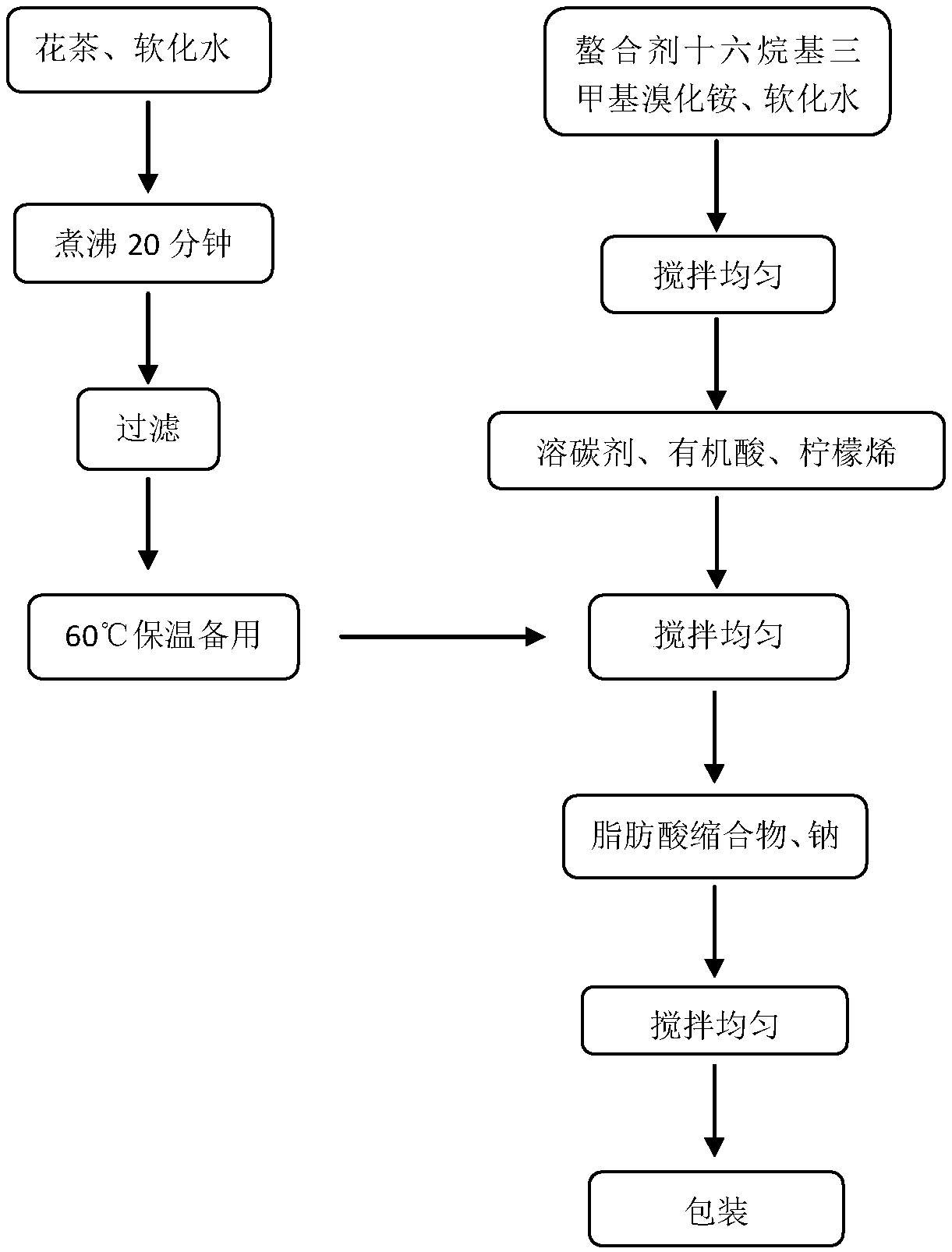

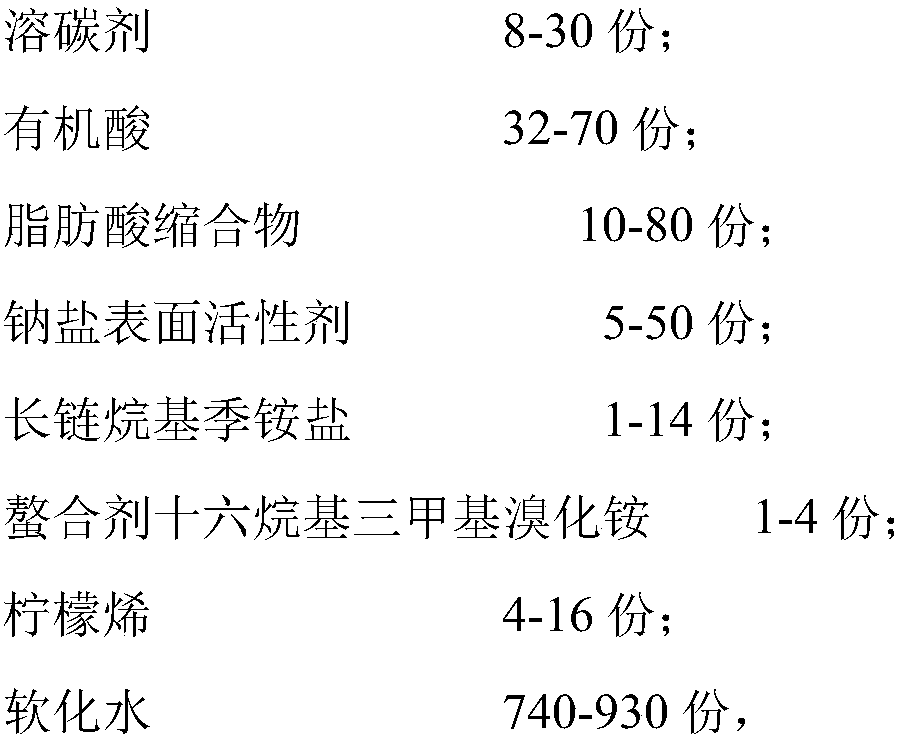

[0036] (1) Put 2 g of scented tea and 500 g of demineralized water into a container and boil, keep boiling for 20 minutes to obtain scented tea water with scented tea;

[0037] (2) filtering the scented tea in the scented tea water obtained in (1), to obtain scented tea water without solid residue;

[0038] (3) heat the scented tea water obtained in (2) at 60°C for subsequent use;

[0039] (4) chelating agent cetyltrimethylammonium bromide 3g is mixed with demineralized water 430g, stirs;

[0040](5) Add cyclohexane 10g, nano-titanium dioxide 6g, fumed white carbon black 6g, tartaric acid 10g, glacial acetic acid 11g, malic acid 11g, limonene 16g successively in the mixture obtained in step (4), stir;

[0041] (6) Add scented tea water obtained in step (3), stir evenly;

[0042] (7) Add 20 g of fatty acid polyethylene glycol ester, 20 g of fatty acid amide polyethylene glycol ether, 20 g of fatty acid diethanol amide, 20 g of sodium salt of fatty acid sulfosuccinate, 20 g of...

Embodiment 2

[0044] (1) Put 1 g of scented tea and 400 g of demineralized water into a container to boil, and keep boiling for 20 minutes to obtain scented tea water with scented tea;

[0045] (2) filtering the scented tea in the scented tea water obtained in (1), to obtain scented tea water without solid residue;

[0046] (3) heat the scented tea water obtained in (2) at 60°C for subsequent use;

[0047] (4) chelating agent cetyltrimethylammonium bromide 1g is mixed with demineralized water 340g, stirs;

[0048] (5) Add cyclohexane 4g, nano-titanium dioxide 10g, fumed silica 2g, citric acid 20g, tartaric acid 25g, malic acid 25g, limonene 10g successively in the mixture obtained in step (4), stir;

[0049] (6) Add scented tea water obtained in step (3), stir evenly;

[0050] (7) Add fatty acid polyethylene glycol ester 2g, fatty acid amide polyethylene glycol ether 3g, fatty acid diethanolamide 2g, fatty acid sulfosuccinate sodium salt 3g, sodium dodecylsulfonate 2g, alkylphenol Ether ...

Embodiment 3

[0052] (1) Put 1.5 g of scented tea and 450 g of demineralized water into a container and boil, keep boiling for 20 minutes to obtain scented tea water with scented tea;

[0053] (2) filtering the scented tea in the scented tea water obtained in (1), to obtain scented tea water without solid residue;

[0054] (3) heat the scented tea water obtained in (2) at 60°C for subsequent use;

[0055] (4) chelating agent cetyltrimethylammonium bromide 4g is mixed with demineralized water 400g, stirs;

[0056] (5) Add cyclohexane 6g, nano-titanium dioxide 2g, fumed silica 10g, citric acid 27g, glacial acetic acid 28g, limonene 4g successively in the mixture obtained in step (4), stir;

[0057] (6) Add scented tea water obtained in step (3), stir evenly;

[0058] (7) Add fatty acid polyethylene glycol ester 10g, fatty acid amide polyethylene glycol ether 10g, fatty acid diethanolamide 8g, fatty acid sulfosuccinate sodium salt 9g, sodium dodecylsulfonate 11g, alkylphenol Ether sulfosucc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com