Spare part membrane-coating method before partially plating gold on reed

A partial gold-plating and reed technology, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of high cost, replacement of mottled gold-plating effect, and inability to batch operation, etc., to achieve low cost, save the use of materials, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

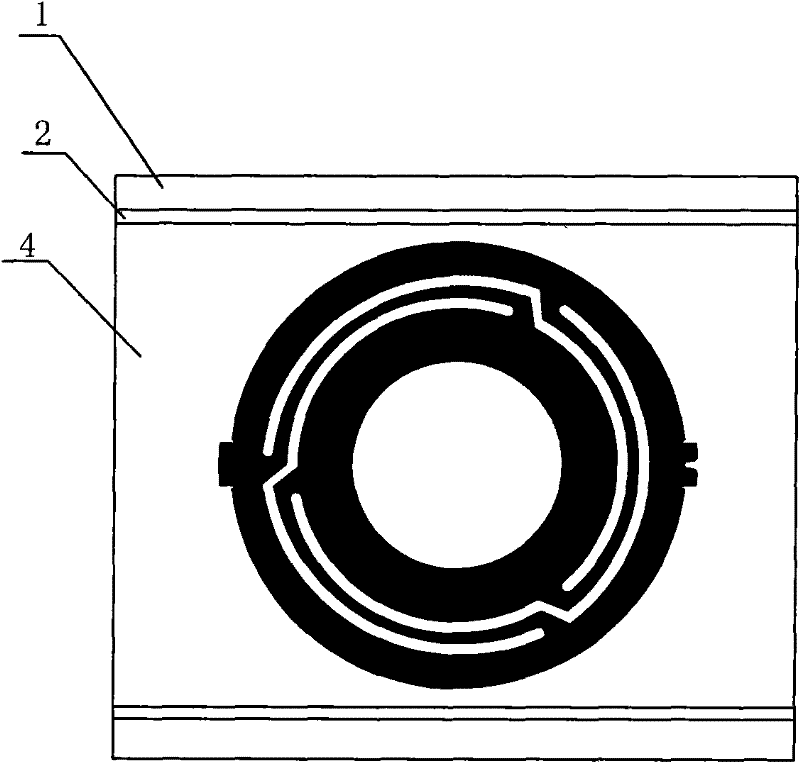

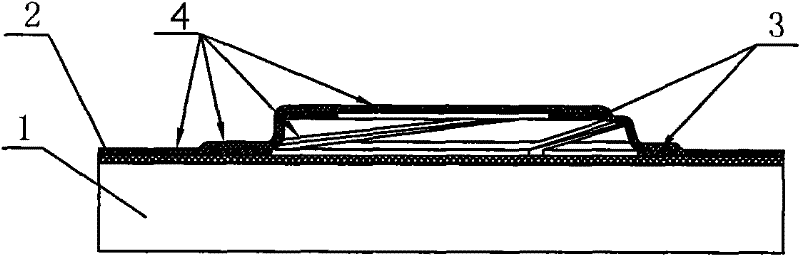

[0074] The specific embodiment of the present invention is a reed (spring leaf) used in a digital geophone. There are two kinds of physical states for the reed peeled off from the whole corroded reed strip, the reed deformed by heat treatment and aging, and the reed deformed by mechanical force. One is that the parts that need to be gold-plated are located on a plane; the other is that the parts that need to be gold-plated are not on a plane (see figure 2, the parts of the deformed reed after heat treatment and aging in the figure that need to be gold-plated are not on the same plane). The method of the present invention is suitable for the coating of the reeds in the above two physical states.

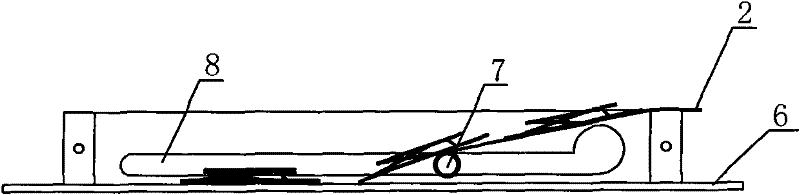

[0075] The first coating method of the present invention can be found in Figure 1 to Figure 4 , including the following steps:

[0076] 1] Cover the dry film on the plate;

[0077] 2] Place at least one reed of any shape on the dry film, where the gold-plated part of the reed fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com