Waterflow energy generator

A generator and water flow technology, applied in hydroelectric power generation, renewable energy power generation, engine components, etc., can solve problems such as abnormal operation, high requirements for dam height and water storage capacity, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

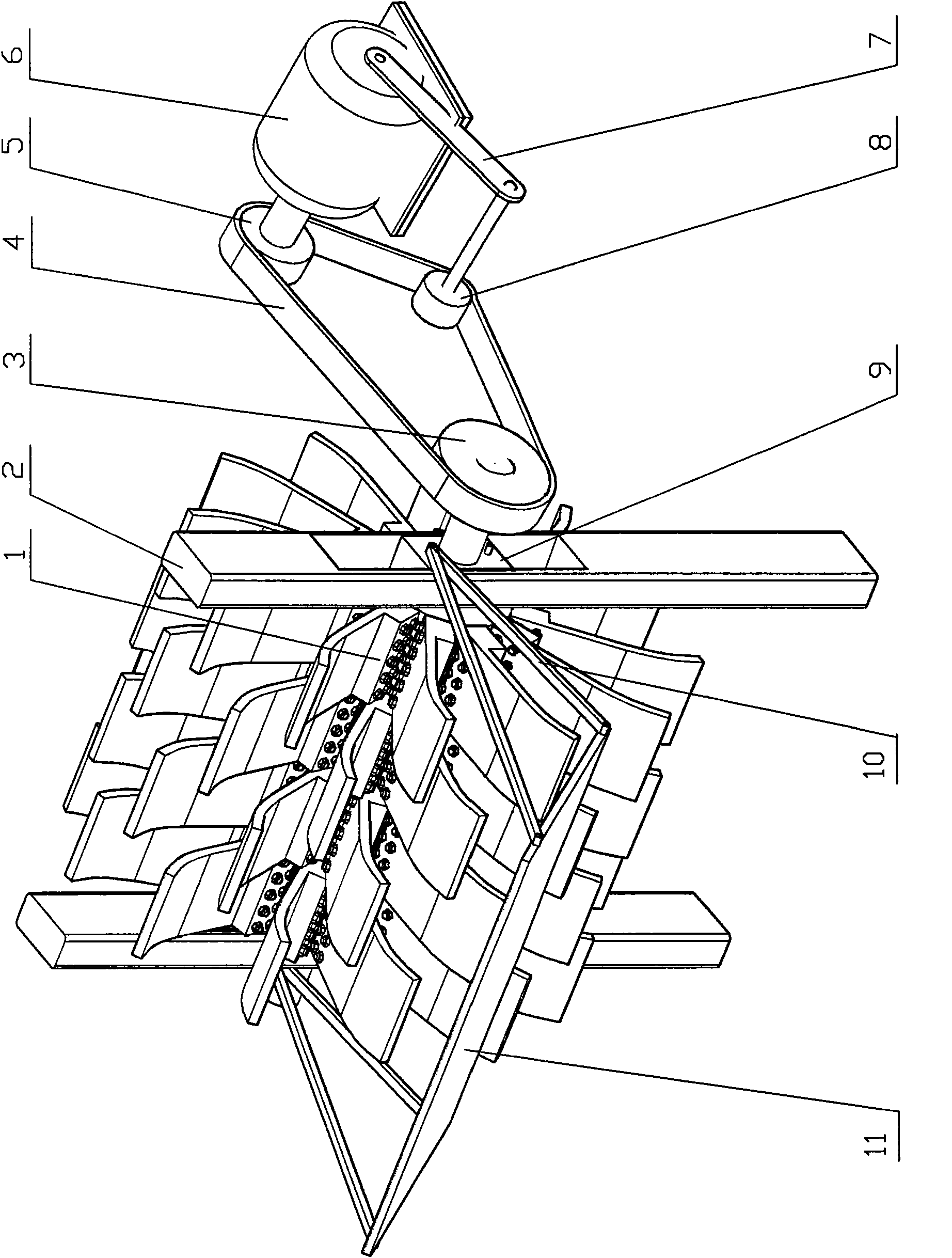

[0019] exist figure 1 , 2 , 3, the water flow energy generator 6 of the present embodiment consists of water wheel 1, column 2, driving pulley 3, belt 4, driven pulley 5, generator 6, adjusting wheel frame 7, adjusting wheel 8, slide block 9, The connecting rod 10 and the energy-gathering deflector 11 are connected to form.

[0020] The two columns 2 are processed with track grooves along the length direction, and a slider 9 is installed in each of the track grooves of the two columns 2. Track grooves are processed on both sides of the slider 9, and the slider 9 can be placed in the track groove of the column 2. Move up and down, the central position of slide block 9 is equipped with waterwheel 1, promptly moves up and down on column 2 with respect to waterwheel 1.

[0021] The left and right ends of the energy-gathering deflector 11 are fixedly installed on the slider 9 of the column 2 with two connecting rods 10 and threaded fastening joints respectively. The shape of the ...

Embodiment 2

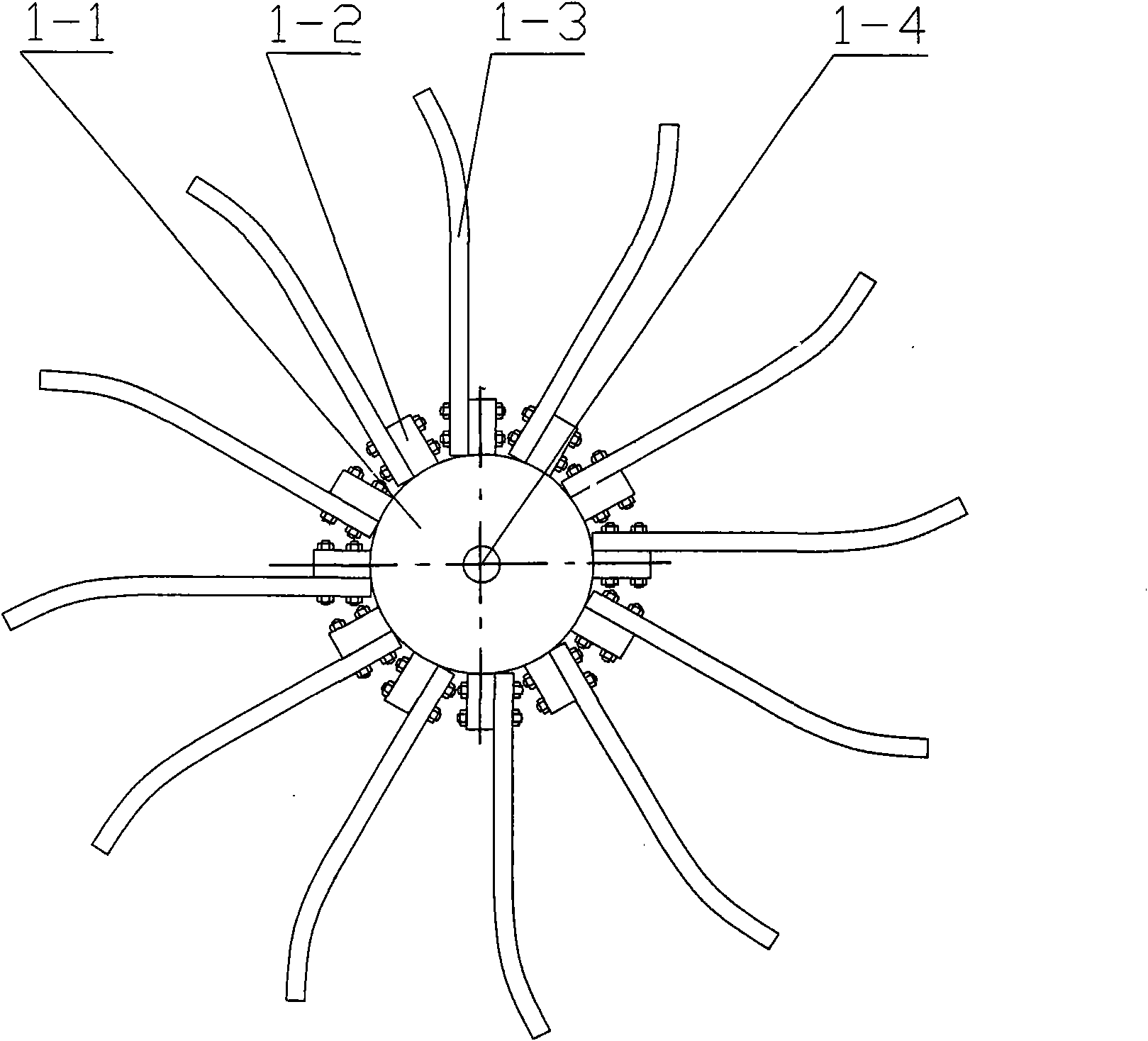

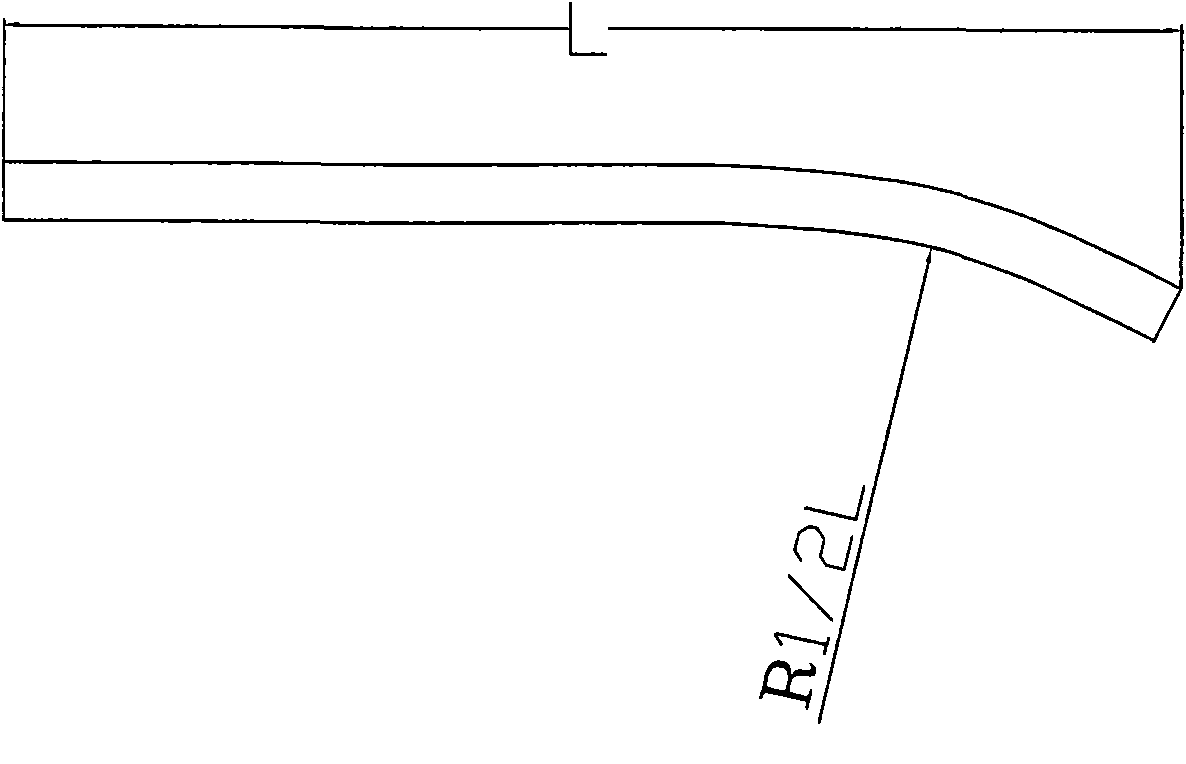

[0024] In this embodiment, the circumference of the outer surface of the buoy 1-1 of the water wheel 1 is fixedly connected with four sets of hubs 1-2 with threaded fastening connectors, and one set of hubs 1-2 is in diameter with the adjacent set of hubs 1-2. Arranged in a staggered direction, each group has 12 radially arranged hubs 1-2 parallel to the axis, and one blade 1-3 is fixedly connected to each hub 1-2 with a threaded fastening connector, and the blade 1 The shape of -3 is a curved plate whose outer end is an arc, and the radius R of the arc is 2 / 5 of the total length of the blades 1-3. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0026] In this embodiment, the circumference of the outer surface of the buoy 1-1 of the water wheel 1 is fixedly connected with four sets of hubs 1-2 with threaded fastening connectors, and one set of hubs 1-2 is in diameter with the adjacent set of hubs 1-2. Arranged in a staggered direction, each group has 12 radially arranged hubs 1-2 parallel to the axis, and one blade 1-3 is fixedly connected to each hub 1-2 with a threaded fastening connector, and the blade 1 The outer end of -3 is arc-shaped, and the radius R of the arc is 3 / 5 of the total length of the blades 1-3. The other parts of the water wheel 1 and the connection relationship of the parts are the same as in the first embodiment. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com