Screwing element and pipe connection device for attaching pipes

A threaded element and a technology for connecting pipe fittings, which are used in the field of pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

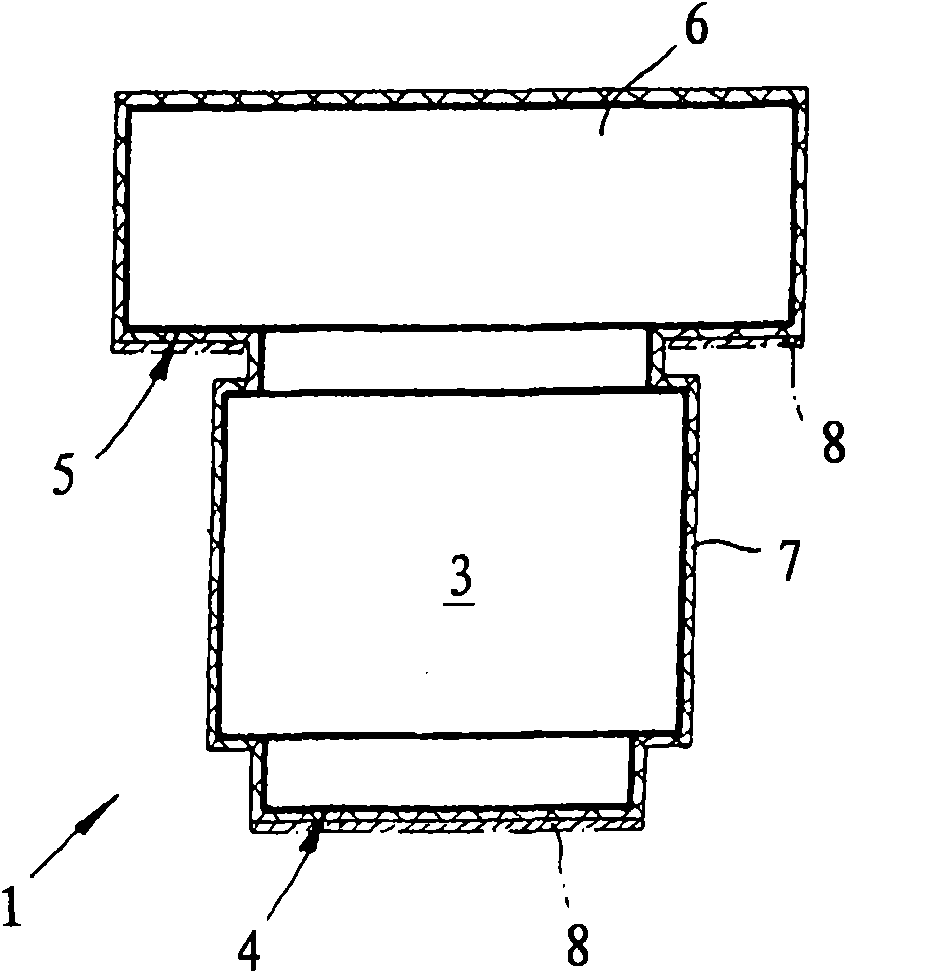

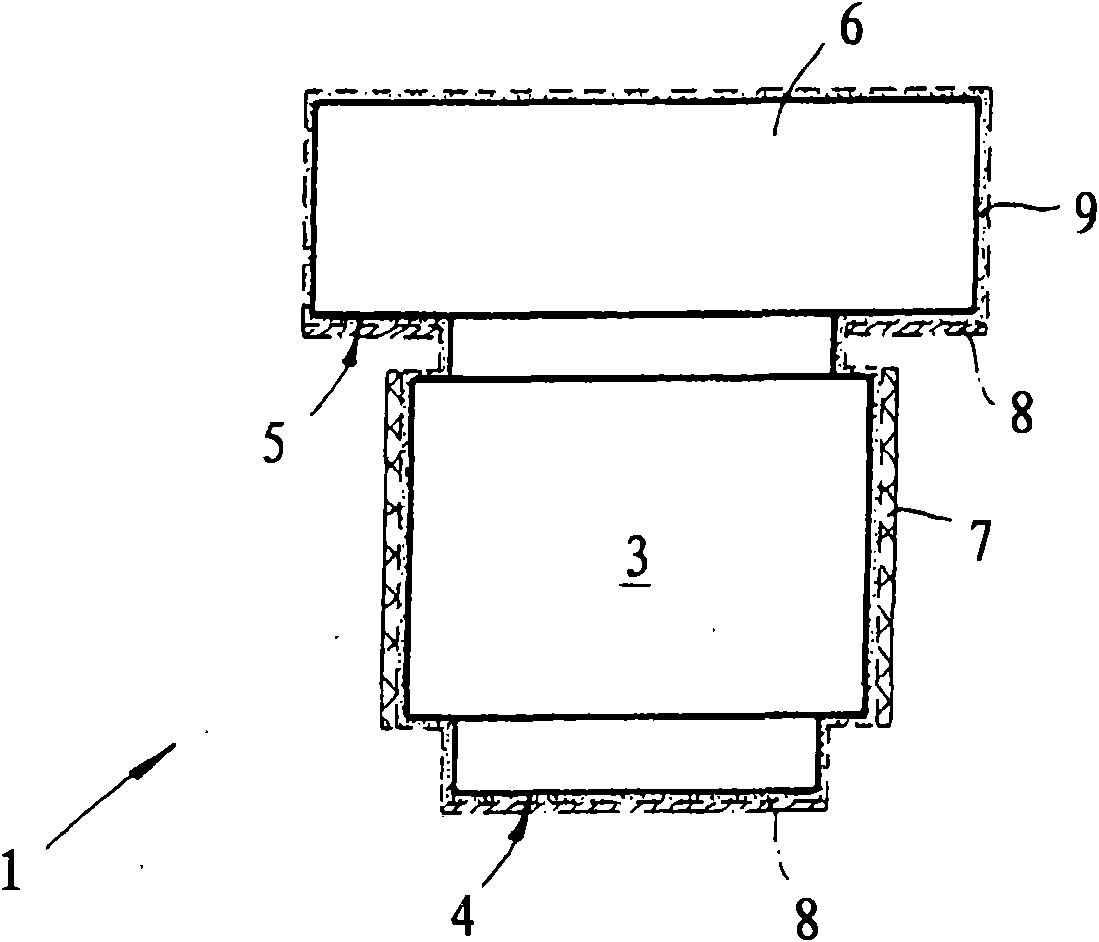

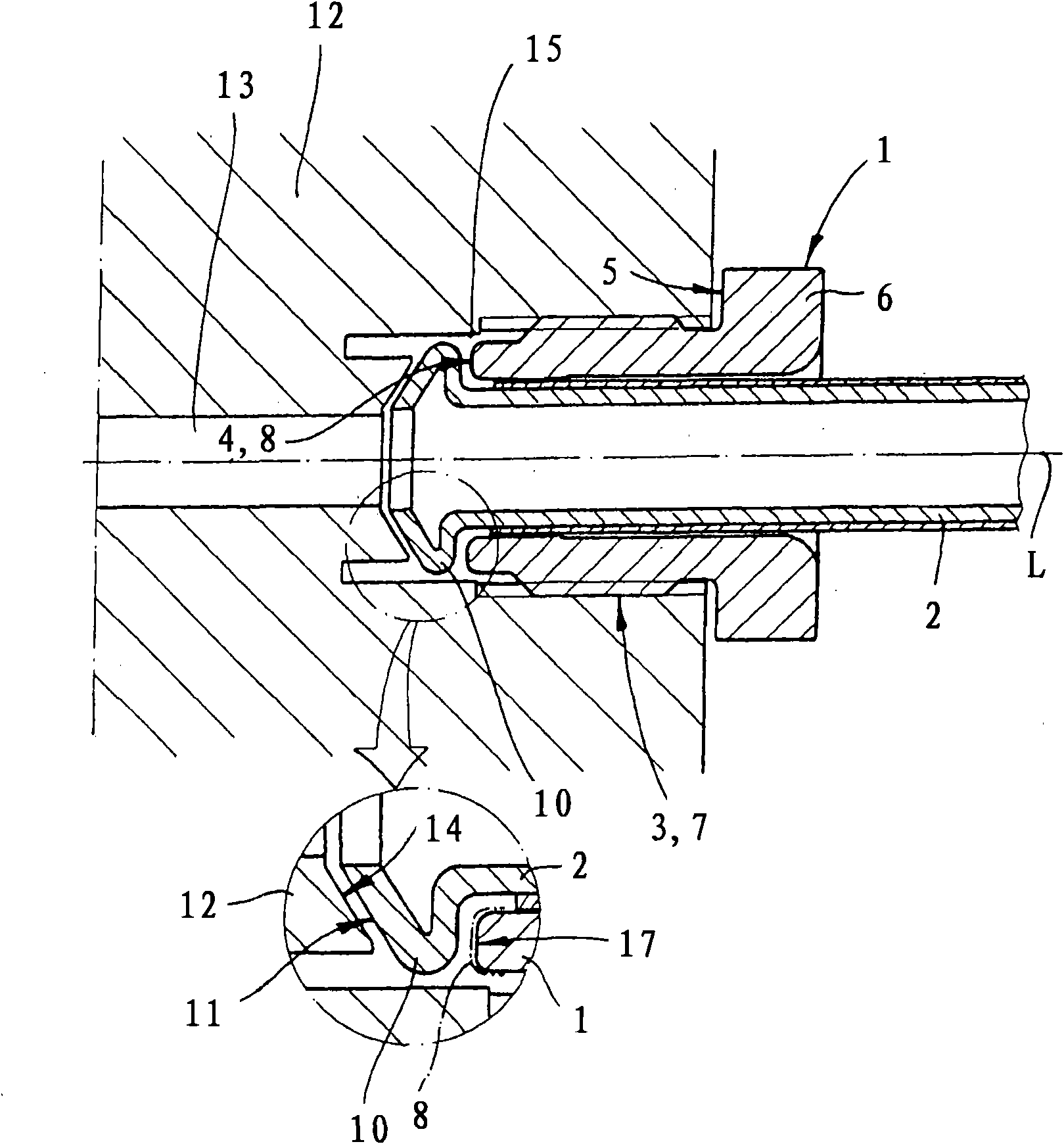

[0030] figure 1 shows the threaded element of the invention of the pipe, which is designed in the form of a screw fitting 1 , preferably, in the case of the illustrated exemplary embodiment, provided for the connection of a pipe body 2 . The pipe body 2 may be a pipe body used in motor vehicles. The screw fitting 1 has a thread 3 and non-threaded contact surfaces 4 , 5 . One of the unthreaded contact surfaces 4 is arranged on the end of the screw fitting 1 and the other unthreaded contact surface 5 is arranged on the underside of the element head 6 - that is to say on the side facing the thread superior. Preferably, in the case of the illustrated exemplary embodiment, the thread 3 or the external thread on the screw fitting 6 is provided with a first higher coefficient of friction μ 1 The first coat 7 is completely covered. Preferably, in the case of the illustrated exemplary embodiment, the entire surface of the two unthreaded contact surfaces 4, 5 is provided with a coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com