Longitudinal axial flow threshing and cleaning testing device

A test device and cleaning device technology, which is applied in the direction of measuring device, threshing equipment, machine/structural component testing, etc., can solve the problems of poor cleaning effect, running grain, entrainment loss increase, etc., to achieve convenient parameter adjustment, Easy to measure and monitor overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

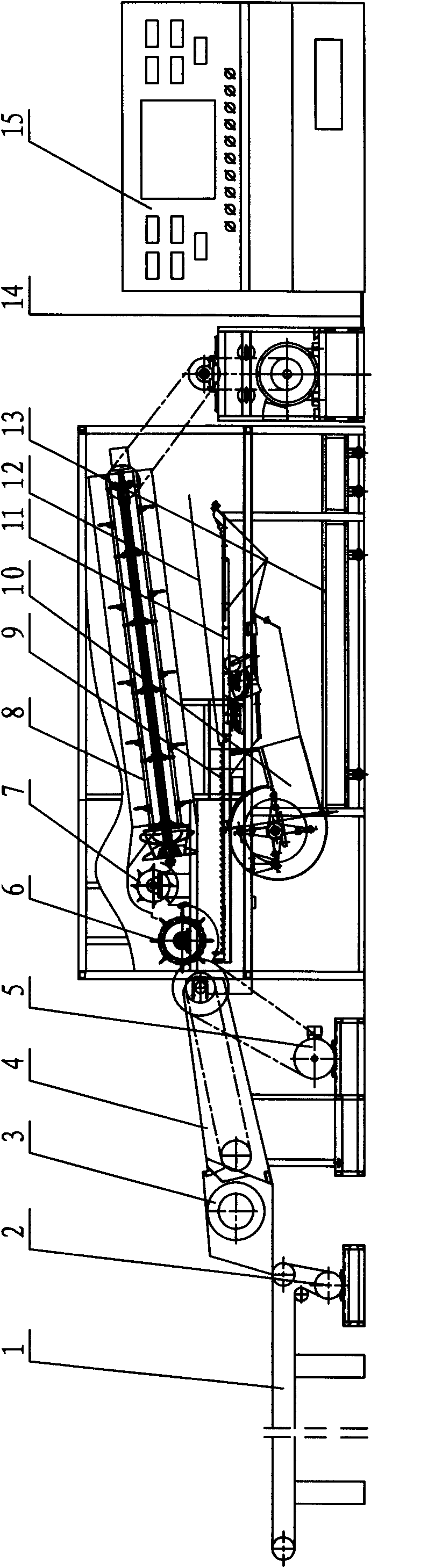

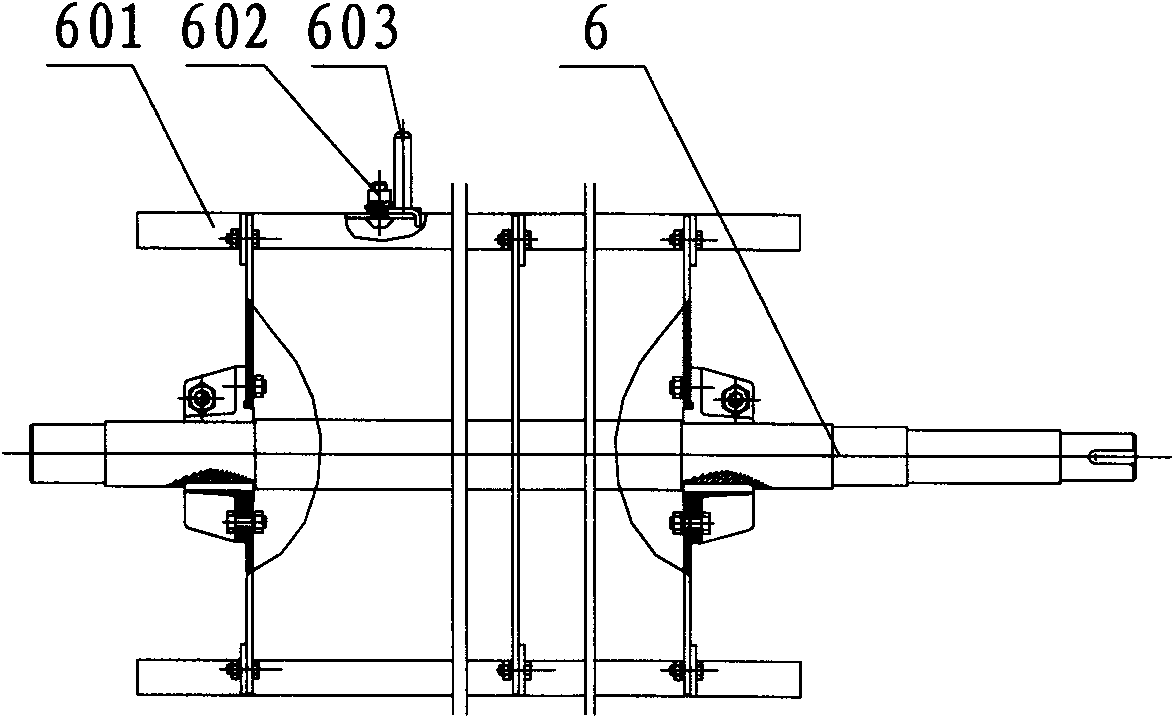

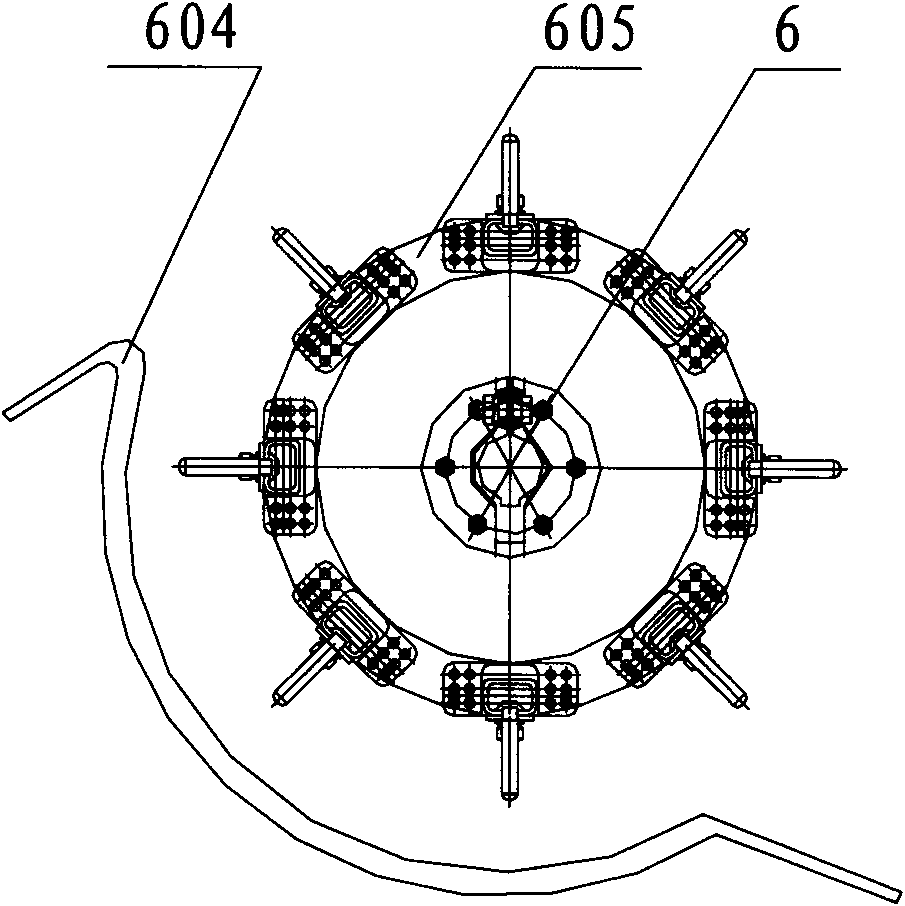

[0031] see Figure 1-7 , The structure diagram of the vertical axial flow threshing and cleaning test device and the structure diagram of each component, including the material conveying device, the material feeding device, the longitudinal axial flow threshing and separating device, the cleaning device and the detection and control device. The rear part of the material conveying device 1 is connected to the front part of the feeding screw 3 in the feeding device, and the rear part of the feeding screw 3 is connected to the cutting flow threshing separation device 6 through the conveying groove 4, and the cutting flow threshing separation device 6 is connected to Auxiliary feeding device 7, the rear of the auxiliary feeding device 7 is connected to the longitudinal axial flow threshing and separating device 8, the cleaning device is installed below the longitudinal axial flow threshing and separating device 8, and the detection and control device controls the motion parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com