Method for making sucking moulding luminescent words of Phi 4mm electrodeless lamps

A manufacturing method and electrodeless lamp technology, which are applied in the use of gas discharge lamps, light sources, electric light sources, etc., can solve the problems of difficult manufacturing processes and difficult to make inverters, and achieve low energy consumption, good economic benefits and environmental benefits. , the effect of uniform brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

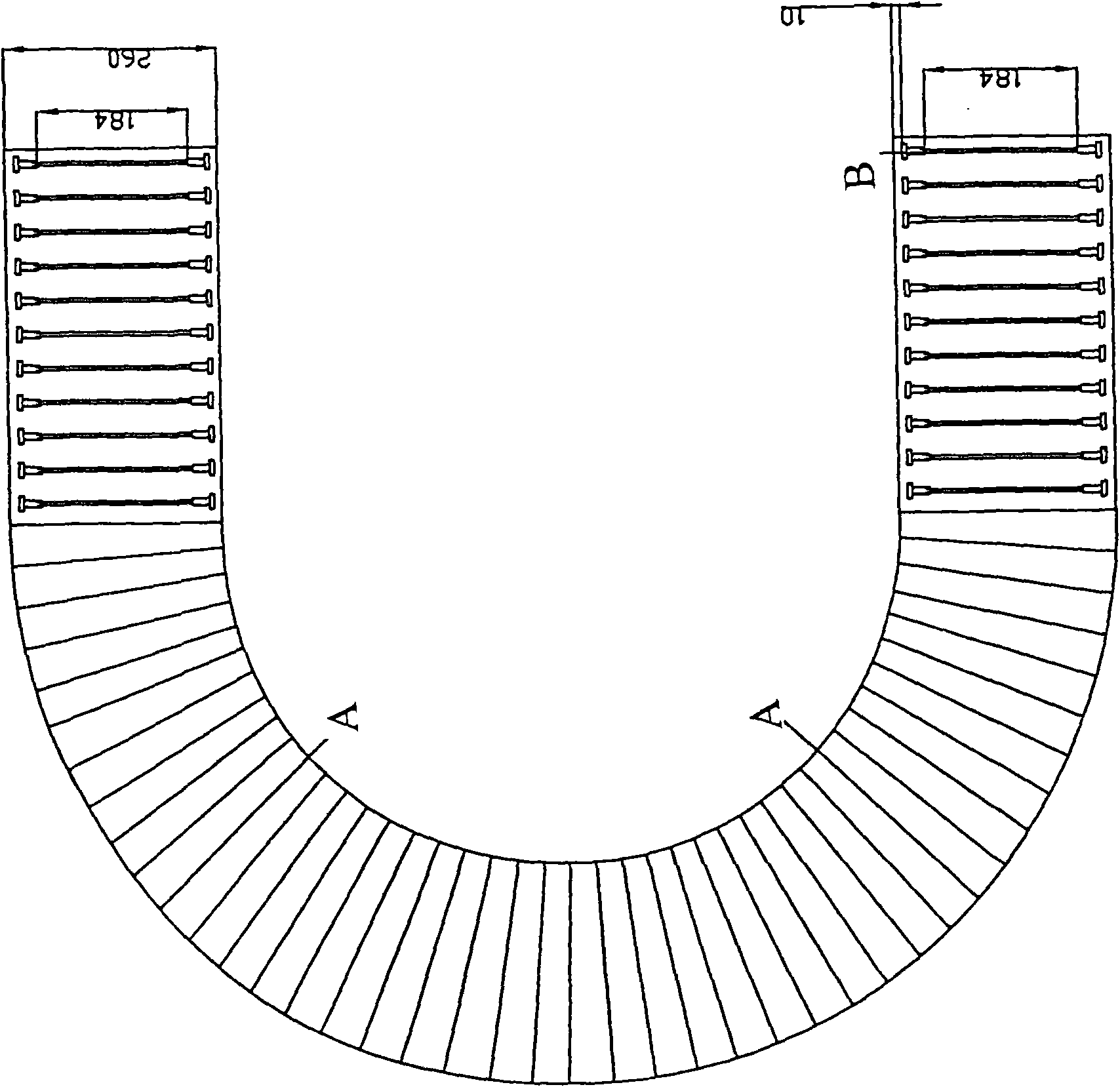

[0016] Embodiment 1: Make a luminous character of the letter 'C', the character height is 1320mm, the character width is 1108mm, and the stroke width is 260mm. The production method is divided into the following process steps:

[0017] Step 1. According to the stroke size of the word 'C', draw the lamp tube arrangement and installation diagram of the letter C.

[0018] Step 2. Arrange the Φ4mm lamp tubes evenly according to the lamp positioning card with an interval of 50mm, and connect the lamp cap (the distance between the cap and the edge is 5mm)

[0019] Step 3. A total of 65 lamps are needed, divided into 3 groups with three inverters, among which there are two A inverters with 22 lamps each, and the other B inverter with 21 lamps. Subtract 40mm from the side length to get the length of the lamp tube to be 220mm.

[0020] 6 fire-resistant and flame-retardant lamp holder wires: 4 for 22 lamps, 2 for 21 lamps.

[0021] 22 plastic strips for lamp tubes (distance 40mm, 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com