Dust cup device for dust collector

A technology of vacuum cleaners and dust cups, which is applied in the direction of suction filters, etc., can solve the problems of limited separation effect, complicated air flow channel, and large air flow resistance, and achieve the effect of improving separation effect, improving separation effect and reducing gas resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

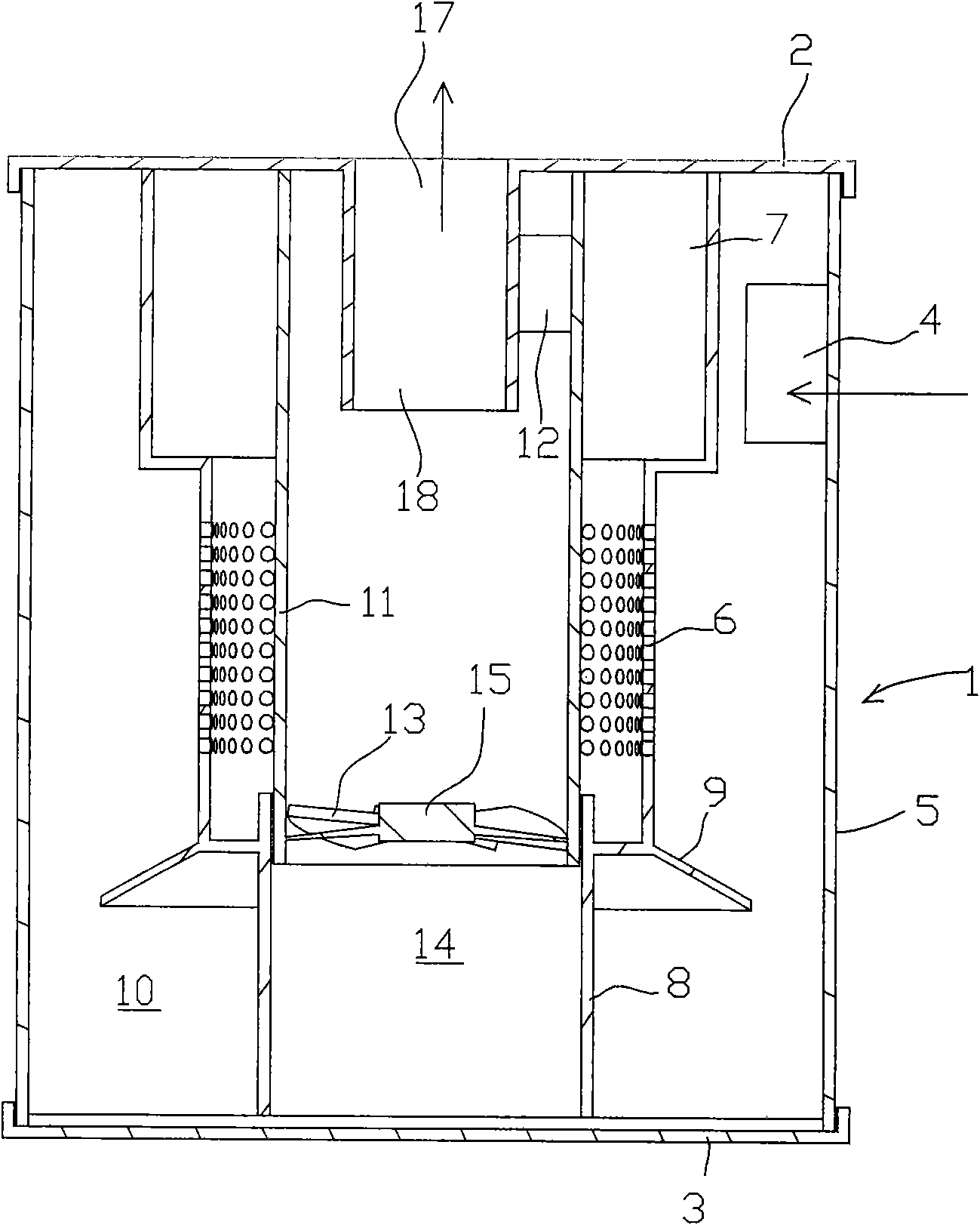

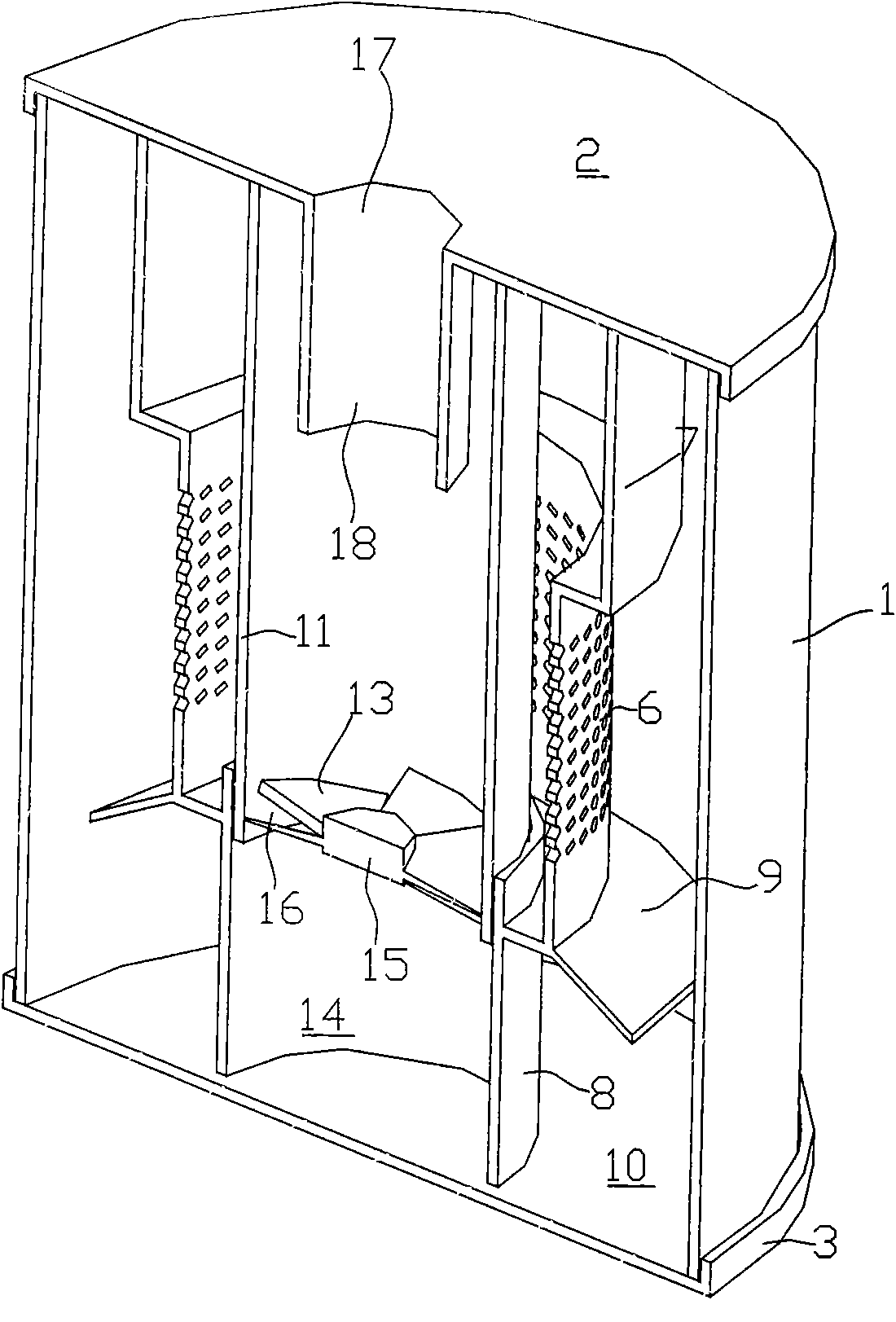

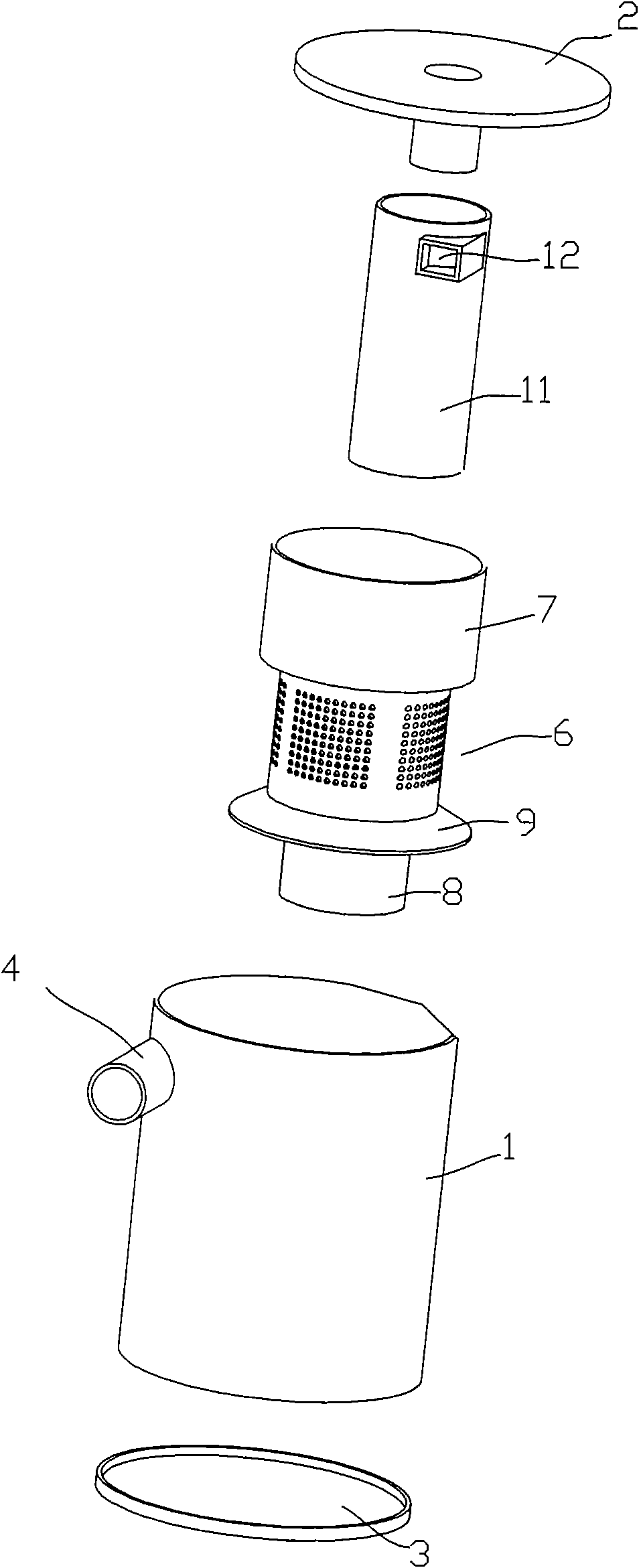

[0022] Such as Figure 1-5 Shown is a dust cup device for a vacuum cleaner, which includes a cup body 1, a cup cover 2 and other components, wherein the upper part of the cup body 1 has a tangential general air inlet 4 for easy air intake, and the cup body is divided into a main body 5 and a lower end. The cup bottom 3 is fixed on the lower end of the cup body 1 through a detachable connection such as threaded connection or clip connection, and there is also a cylindrical microporous filter 6 with a filtering effect. The filter 6 extends upwards with a diameter-enlarged, hollow cylindrical sleeve as the upper end sleeve 7, and extends downward with a diameter-reduced, hollow cylindrical sleeve as the lower end sleeve 8, so that It is directly arranged between the cup cover 2 and the cup bottom 3 of the dust cup. In order to limit the position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com