Hand press

A manual press and press bar technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of high manufacturing cost and complicated structure of manual presses, and achieve low manufacturing cost, simple structure, and lightweight model. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

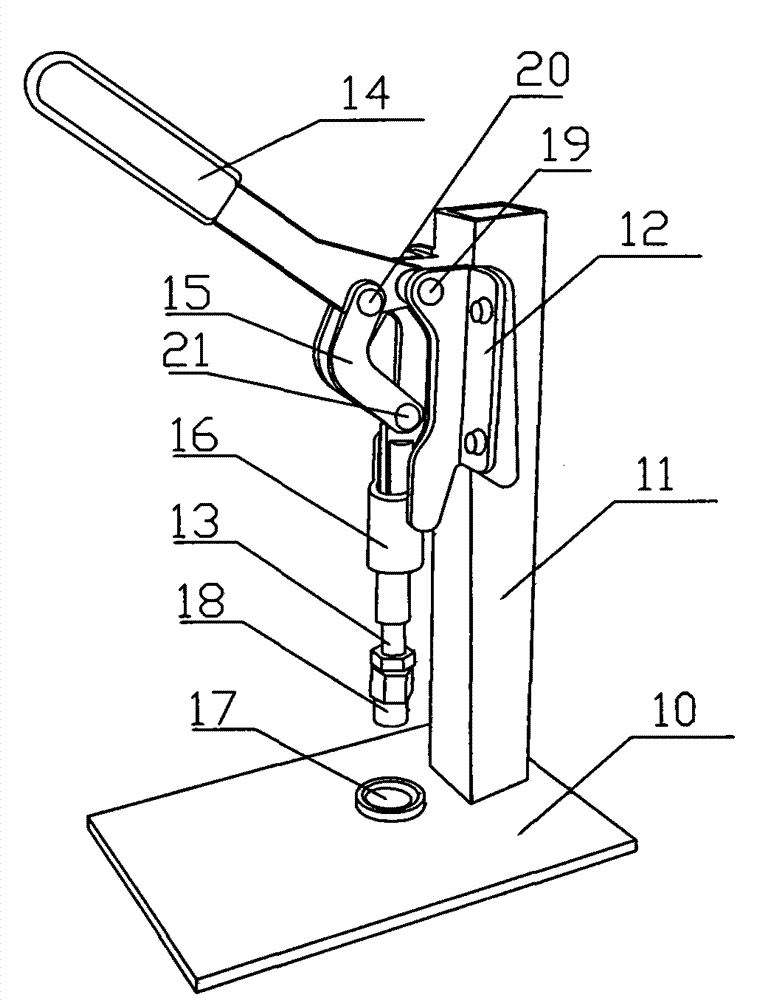

[0015] figure 1 A preferred embodiment of the invention is shown.

[0016] see figure 1 As shown, the manual press includes a machine base 10, a square column 11 on the base 10, and a pressing device is arranged on the column 11. The pressing device comprises a manual pressure rod 14, a connecting rod 15, a pressure rod 13, a guide member, and the guide member includes a fixed block 12 and a guide portion 16 fixedly connected to the lower end of the fixed block 12, and the fixed block 12 includes a left and right fixed block, and the fixed block 12 includes a left and right fixed block. Rivets are symmetrically fixed on the top of the column 12, and the distance between the left and right fixed blocks is compatible with the thickness of the manual lever 14 and the peripheral dimensions of the guide part 16; It can be a square hole or a circular hole or a hole of other shapes. The depression rod 13 is placed in the inner hole of the guide part 16 and can slide up and down in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com