Tobacco shred storage box

A storage box and shredded tobacco technology, applied in unloading devices, containers, packaging, etc., can solve problems such as system paralysis and lack of reliability, and achieve the effect of improved reliability and flexible transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

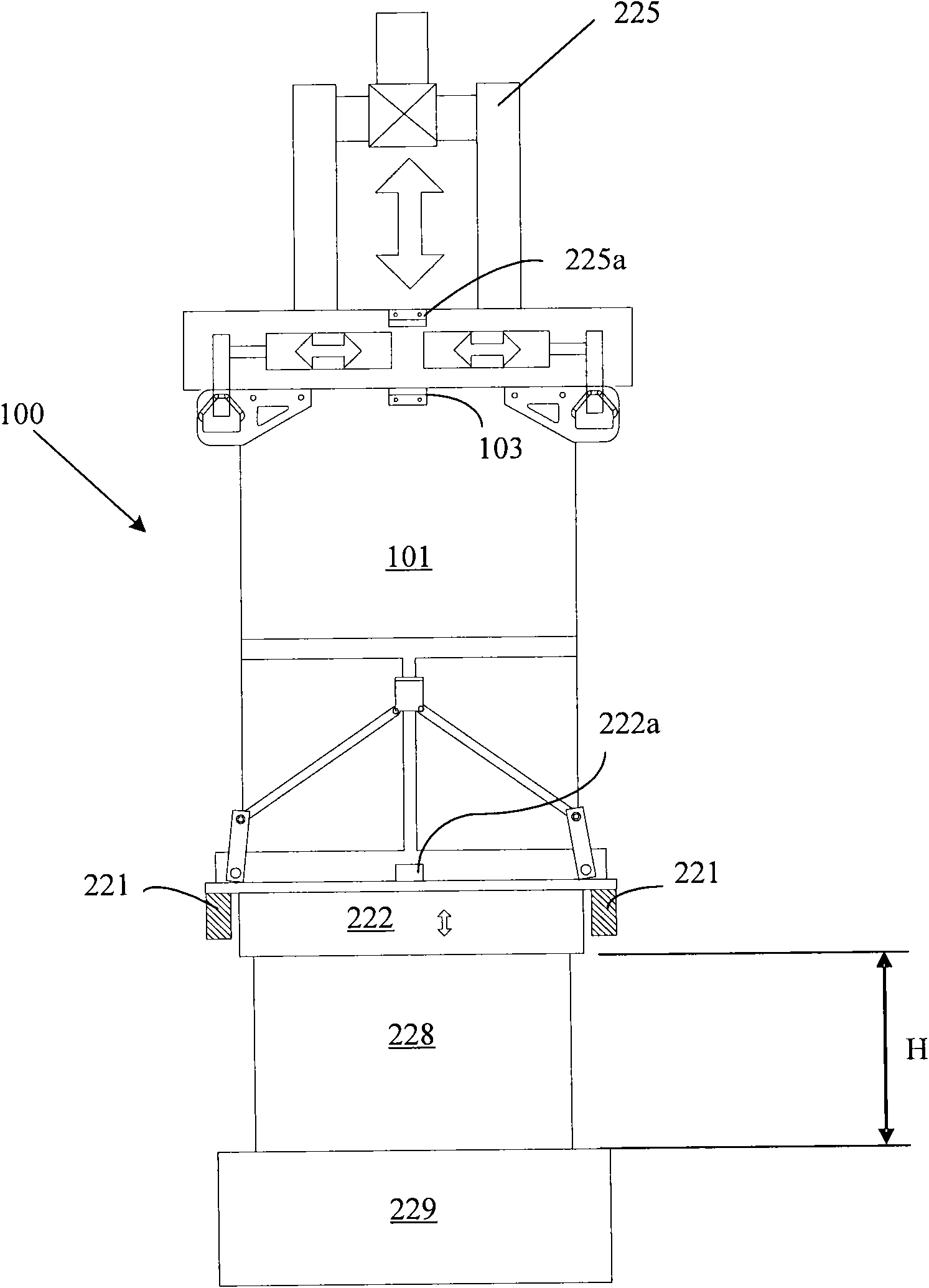

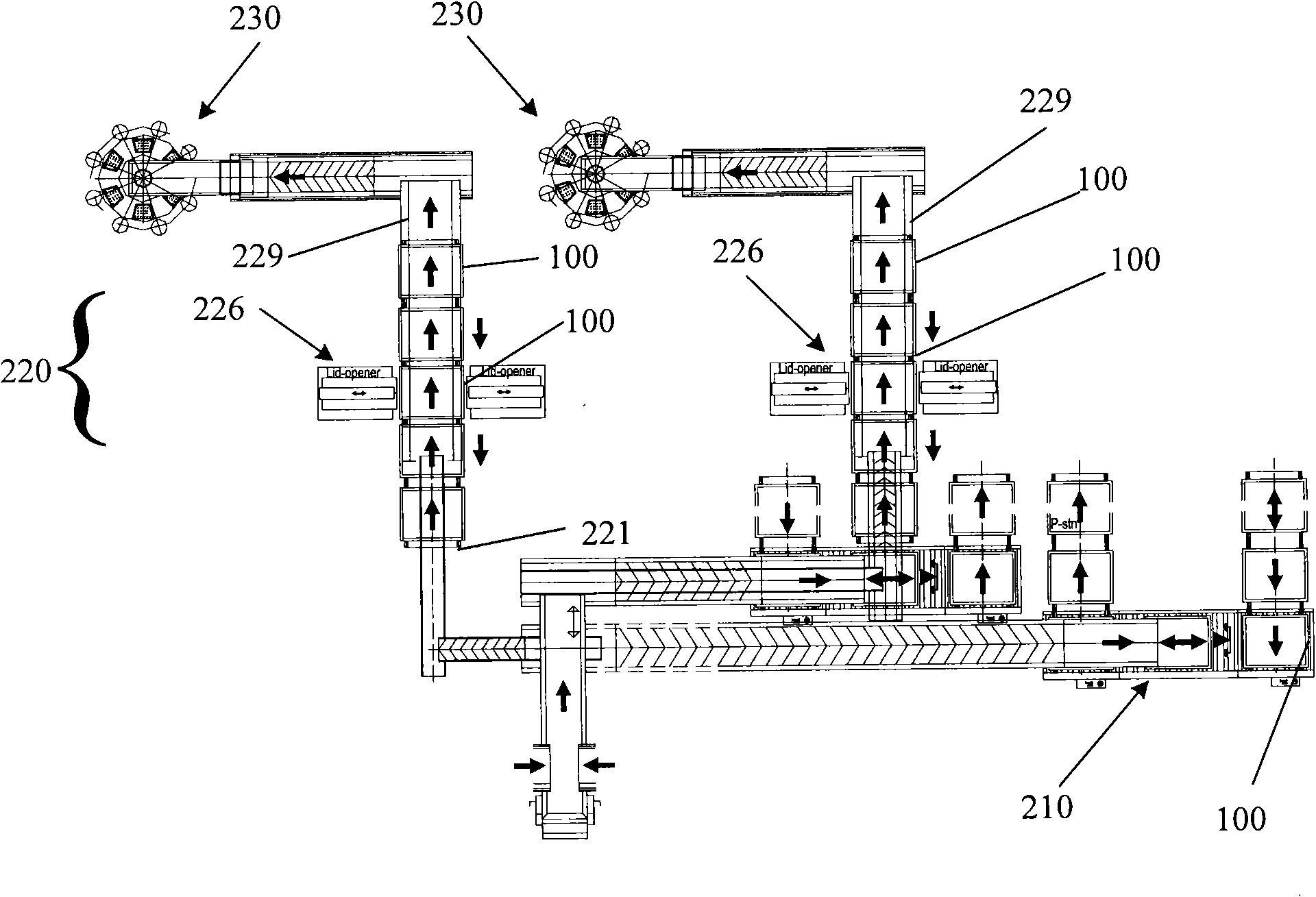

[0020] The shredded tobacco storage box of the present invention is used for transporting shredded tobacco material from the shredded storage cabinet system to the unloading station of the wind-forced wire feeder, or from the shredded tobacco storage cabinet system to the transfer station of the material storehouse. Through the description of the shredded tobacco storage box of the following embodiment, it will be understood how the present invention achieves flexible and reliable delivery.

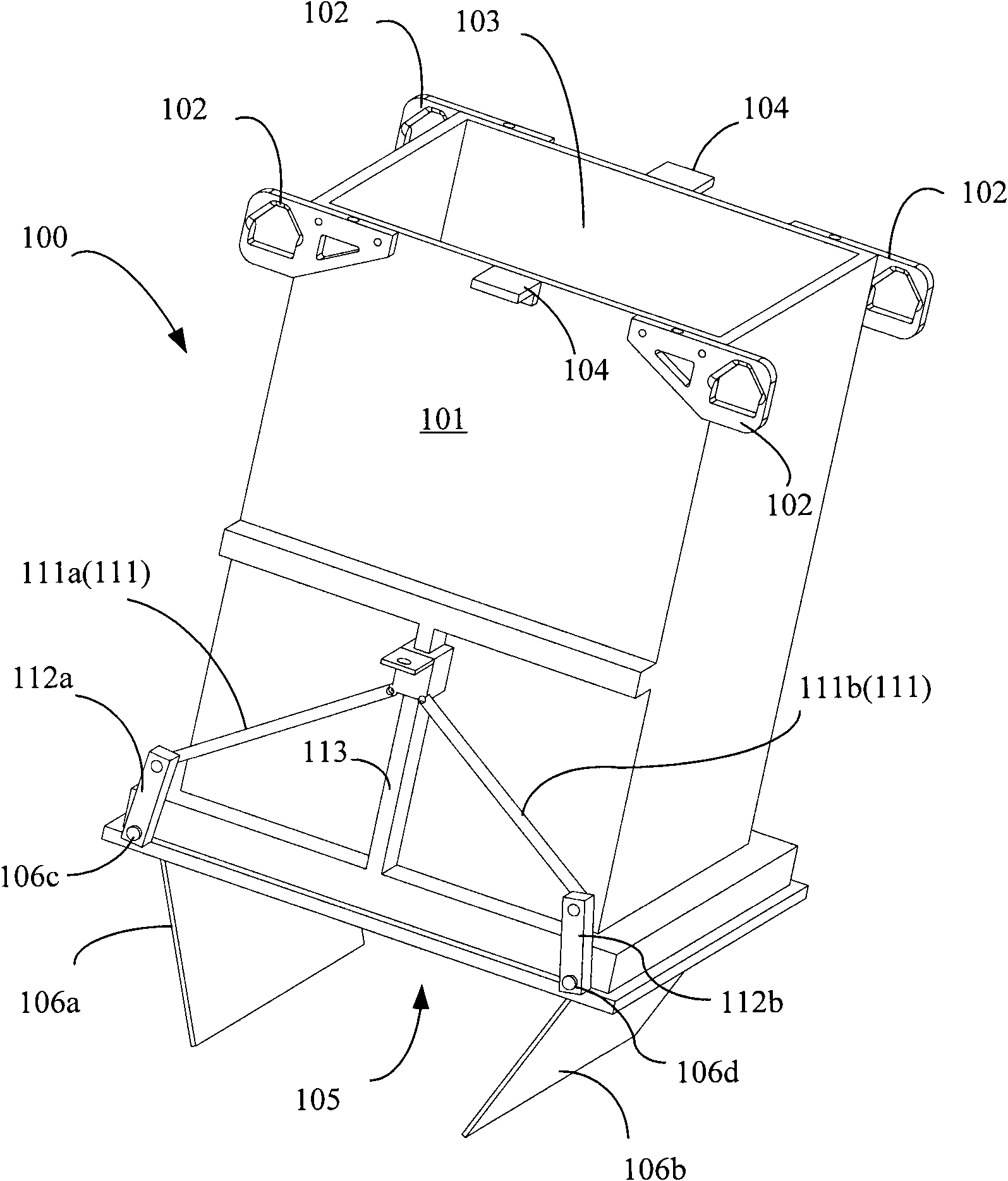

[0021] refer to Figure 1A As shown, the shredded tobacco storage box 100 includes a box body 101, and the material of the part in contact with the material (such as the inside of the box body) must meet the safety standards of the US FDA or the German Bgvv drug and food industry. The material is, for example, stainless steel. In addition, other requirements to be met include: no moisture or water condensation, no sticking, no static electricity, no odor transfer, no loose parts (to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com