Keeper joint, keeper unit, scribing head and scribing device

A holder and scribing head technology, which is applied to glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of low position accuracy, difficulty in dismounting, and difficulty in removing the holder, and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

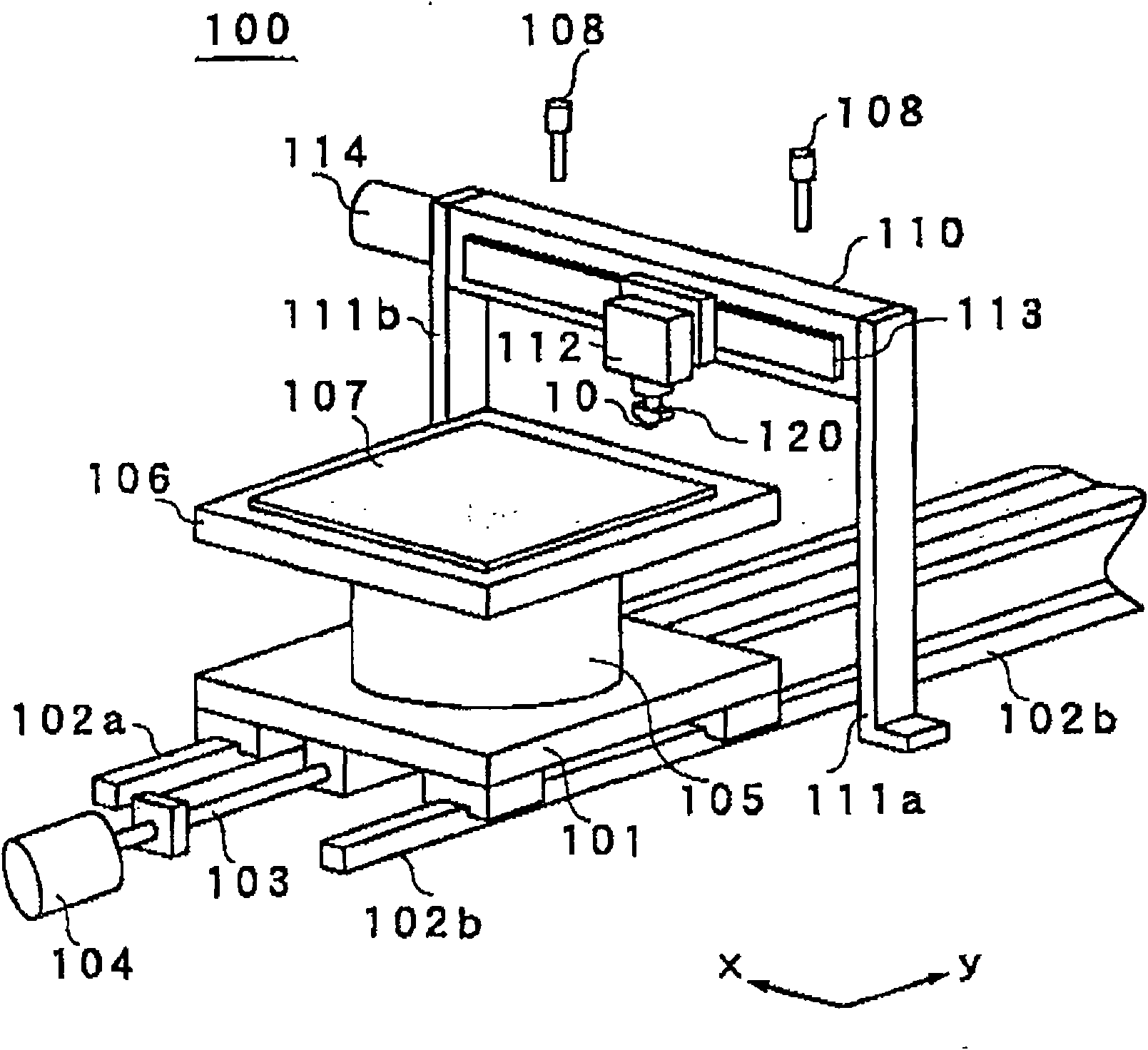

[0042] Figure 8 It is a perspective view showing a scribing device using a scribing head according to an embodiment of the present invention. In this scribing device, the same symbols are given to the same parts as those in the above-mentioned conventional example. In the scribing device 1 of the present embodiment, the moving table 101 is held movably in the y-axis direction along a pair of guide rails 102a and 102b. The ball screw 103 is screwed with the moving table 101 . The ball screw 103 is driven and rotated by the motor 104 to move the moving table 101 in the y-axis direction along the guide rails 102a and 102b. A motor 105 is provided on the upper surface of the mobile stand 101 . The motor 105 rotates the platform 106 on the xy plane to be positioned at a predetermined angle. The brittle ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com